TM 5-809-3/NAVFAC DM-2.9/AFM 88-3, Chap. 3

units are typically 15e inches long; either 7e

suitable for use in concrete such as coloring pig-

inches or 3e inches high; and 7e inches, 5e

ments, ground silica, etc., may also be used.

inches, or 3e inches wide. Nominal widths up to

b. Manufacturing process. Concrete masonry

units are cast using no slump concrete. The mixture

16 inches are also available in many areas. The

is placed into molds and vibrated under pressure for

walls of most hollow concrete units taper or are

a specified time to obtain compaction. Higher

flared and thicker on one bed surface of the unit

strength units can be obtained by subjecting the

than the other to enable release from the mold

material to longer vibration and compaction

during production. Hence, the net concrete cross-

periods. The units are removed from the molds and

sectional area may be greater on the top of the unit

may be cured under normal atmospheric conditions,

than the bottom. For structural reasons, ASTM C

or by autoclaving (steam curing).

90 stipulates minimum wall thickness for load-

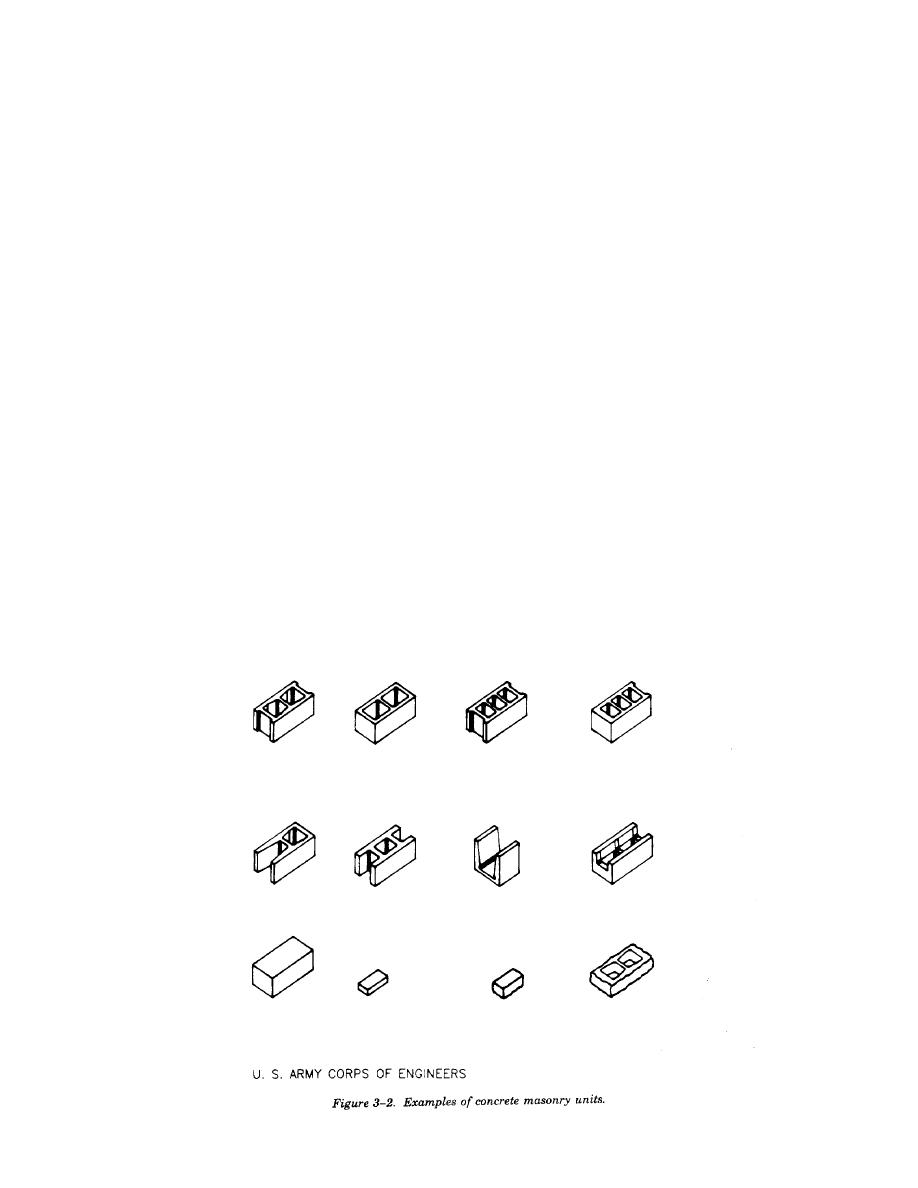

c. Size and shape. Concrete masonry units are

bearing concrete masonry units.

d. Visual properties. Color other than the nor-

available in a wide variety of sizes and shapes as

shown in figure 3-2. They may be classified as

mal concrete gray may be obtained for concrete

hollow or solid.

units by adding pigments into the mix at the time of

(1) A solid unit is defined in ASTM C 90 as

manufacture or by painting after installation. A

having a net area not less than 75 percent of the

variety of surface effects are possible including

gross area. A type of unit known as concrete

smooth face, rough (split) face, and fluted, ribbed,

building brick, ASTM C 55, is available which is

recessed, angular and curved faces, some of which

completely solid. Solid units are typically 7e

may affect cross-sectional area calculations.

e. Classifications. Concrete masonry units are

inches high and are available in several lengths and

widths. Concrete bricks are normally 3e inches

classified according to moisture content require-

wide, 2 inches high and 7e inches or 15e inches

ments. The two types of moisture controlled units

long.

are:

(2) A hollow unit is defined in ASTM C 90 as

(1) Type I, Moisture-Controlled Units, which

having face shell and web thicknesses which con-

must conform to the appropriate ASTM moisture

form to the requirements listed in Table 2 of the C

content requirements.

90 standard. Most hollow concrete masonry units

(2) Type II, Nonmoisture-Controlled Units,

range from 50 to 70 percent of the gross area,

which have no moisture control requirements.

f. Material properties. The material properties

depending on such factors as: unit width, wall (face

shell and web) thickness, and core shape. Hollow

3-3

Previous Page

Previous Page