TM 5-809-3/NAVFAC DM-2.9/AFM 88-3, Chap. 3

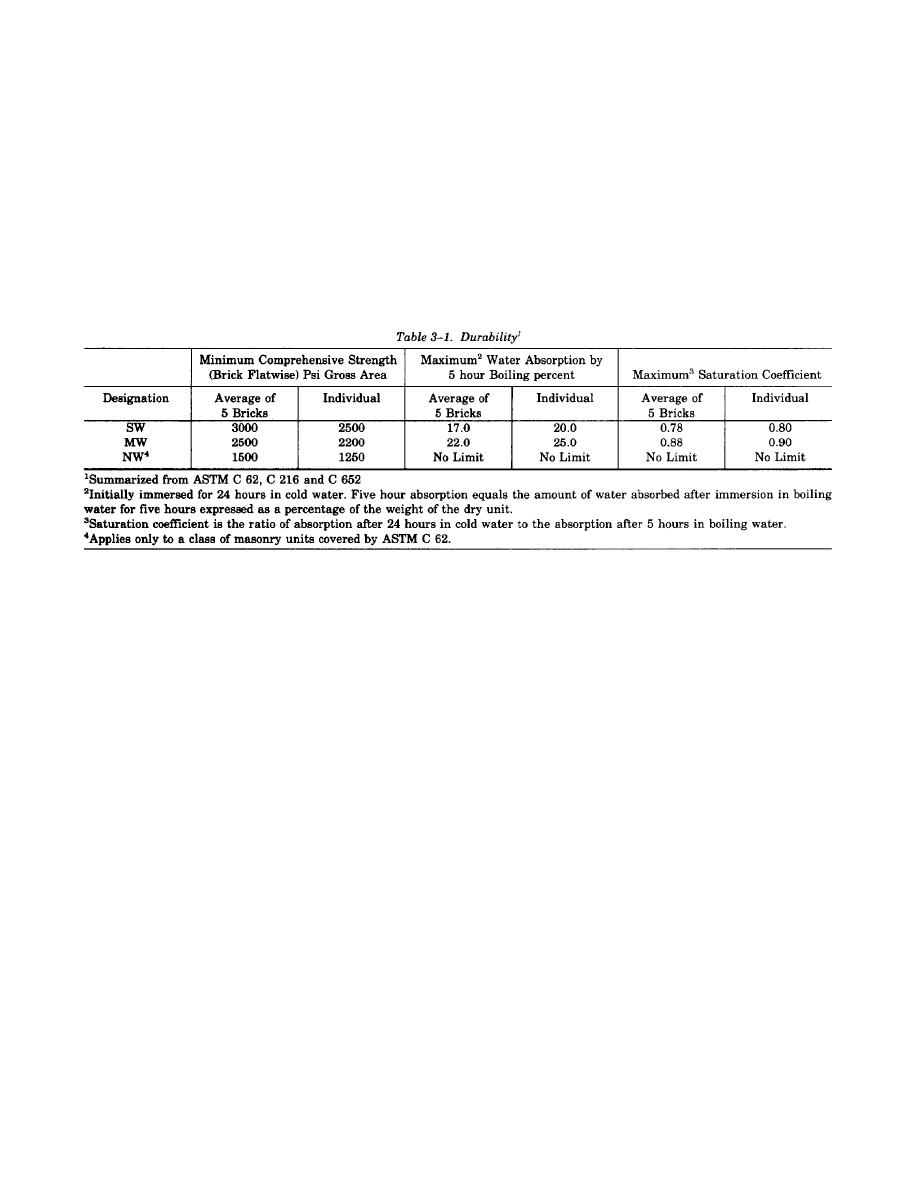

(1) Durability. Durability primarily refers to

thus may influence structural performance. Various

types of surface texturing, which is formed by steel

the ability of a masonry unit to withstand environ-

wire cutting parallel to the direction of extrusion,

mental conditions, such as freeze-thaw action. Clay

may be created on the face surfaces of clay units.

masonry units have been classified in ASTM C 62,

Surface texture is a factor influencing bond

C 216, and C 652 according to their weather

strength between the clay units and the mortar or

resistant capacities into the following grades: Se-

grout.

vere Weathering, SW; Moderate Weathering, MW;

e. Material properties. Material properties of

and No Weathering, NW. Durability, or weather

clay masonry units which can affect their structural

resistance classification, is evaluated in terms of

performance include: durability, initial rate of

compressive strength and water absorption as pre-

absorption, compressive strength, flexural strength,

sented in table 3-1.

and expansion potential.

(2) initial rate of absorption. Clay masonry

the firing temperature and the ambient moisture

units have a tendency to draw water from mortar or

conditions. The initial expansion is irreversible.

grout with which they are in contact due to a

Additional, but small, amounts of contraction or

capillary mechanism caused by small pores in the

expansion due to temporary variations in masonry

units. This phenomenon is termed the initial rate of

moisture content may occur. Clay unit masonry is

absorption, IRA, or suction and has been linked to

also subject to expansion and contraction due to

structural characteristics of masonry such as the

temperature variations.

bond between mortar and the unit. The quality of

bond between mortar and masonry unit is a

3-3. Concrete masonry units. Concrete masonry

function of properties of each. However, for many

units are made from lightweight or normal weight

often used mortar mixes an IRA value in the 10-25

aggregates, or both, to obtain three classes of

grams per 30 square inches per minute range has

masonry units; normal weight, medium weight, and

been observed to be most desirable. Absorption test

lightweight. The structural requirements of ASTM

procedures can be found in ASTM C 67.

C 90 are the same for all classes. Normal weight

(3) Compressive strength. Compressive

units are generally used where lightweight

strength of clay masonry units is measured by

aggregate is not readily available and the cost of

loading specimens to failure in a direction

obtaining the lightweight aggregate does not offset

consistent with the direction of service loading in

the advantages of lightweight units. The advantages

accordance ASTM C 67. Compressive strength of

of lightweight units include ease of handling and

units provides a basis for assuming the compressive

hauling, increased productivity, reduced dead

strength of the masonry assemblage.

loads, improved resistance to thermal flow, im-

(4) Flexural strength. Flexural strength, or

proved absorption of transmitted sound, and higher

modulus of rupture, determined in accordance with

fire resistance. One disadvantage of lightweight

ASTM C 67, is basically a measure of the tensile

units is that they are more porous. This makes them

strength of a masonry unit. It is somewhat corre-

more difficult to paint or seal as required for

lated to unit compressive strength.

interior and exterior exposure.

(5) Expansion potential. Clay masonry units

a. Ingredients. Concrete masonry units primarily

immediately after manufacture are extremely dry

consist of portland cement or blended cement,

and expand due to absorption of moisture from the

aggregate and water. Hydrated lime and/or pozzo-

atmosphere. The magnitude of the initial expansion

lans as well as air entraining agents may be used.

depends on the characteristics of the unit materials,

Other ingredients that have been established as

3-2

Previous Page

Previous Page