UFC 3-280-04

17 DEC 2003

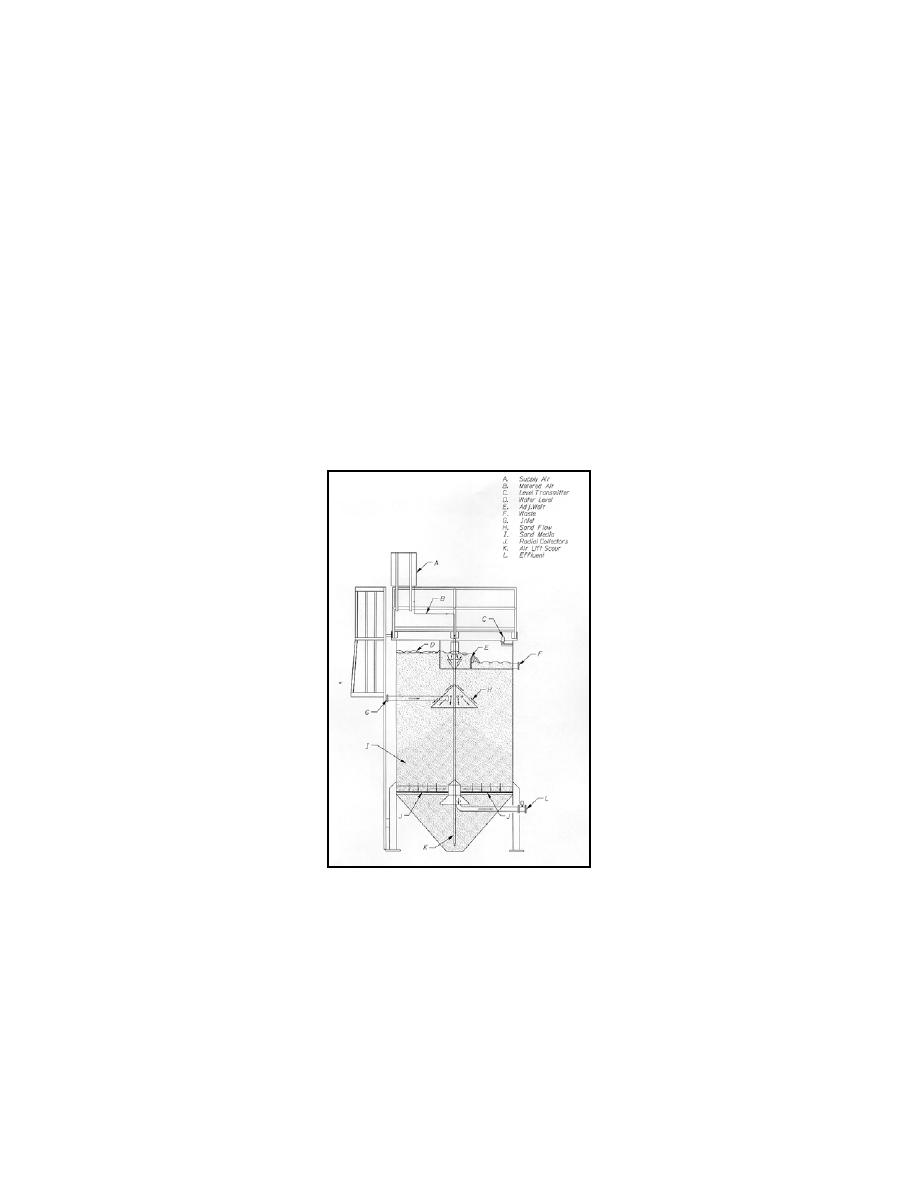

increasingly finer sand, enters a filtrate chamber, and is discharged. The coarse-to-fine

gradation occurs as clean sand falls from the washbox to the top, and center, of the fil-

ter bed. The coarsest sand "rolls" to the periphery of the filter cell while the finest parti-

cles remain at, or near, the peak of the filter bed. This grading process is the result of

gravity's effect on the varying sizes of sand as it seeks its natural angle of repose. The

coarse-to-fine gradation is maintained throughout the depth of the filter as the airlift

pump continually removes the lowest layer of sand for cleaning. The airlift tube assem-

bly transports the sand media and captured solids to the top of the filter. The turbulence

within the assembly separates the sand from the solids. Both sand and solids are

placed into a sand washer chamber, which operates in essentially the same manner as

that employed by the upflow system. The heavier sand falls back into the sand bed and

the solids are discharged through the reject pipe. Figure 5-8 shows a typical downflow

continuous backwash system configuration.

Figure 5-8. Typical Downflow Continuous

Backwash System

Generally, the sand used in the downflow continuous backwash filter is

coarser than the sand layer in granular media filters used in batch processes (12 mm

as opposed to 0.41 mm for the sand layer in dual media filters). The media depth will

be on the order of 1.2 m (4 ft) with a surface loading of 814 (m3/m2)/hr (3.35.7

gpm/ft2). The backwash rate is typically on the order of 10% of the surface loading. Be-

cause of the coarser media grain size and the continuous agitation of the medium and

removed solids, the removal efficiency of the downflow continuous backwash filter is not

as high as is available through gravity and pressure granular media filters. Generally ef-

fluent on the order of 10 mg/L TSS can be expected.

5-25

Previous Page

Previous Page