UFC 3-280-03

23 JULY 2003

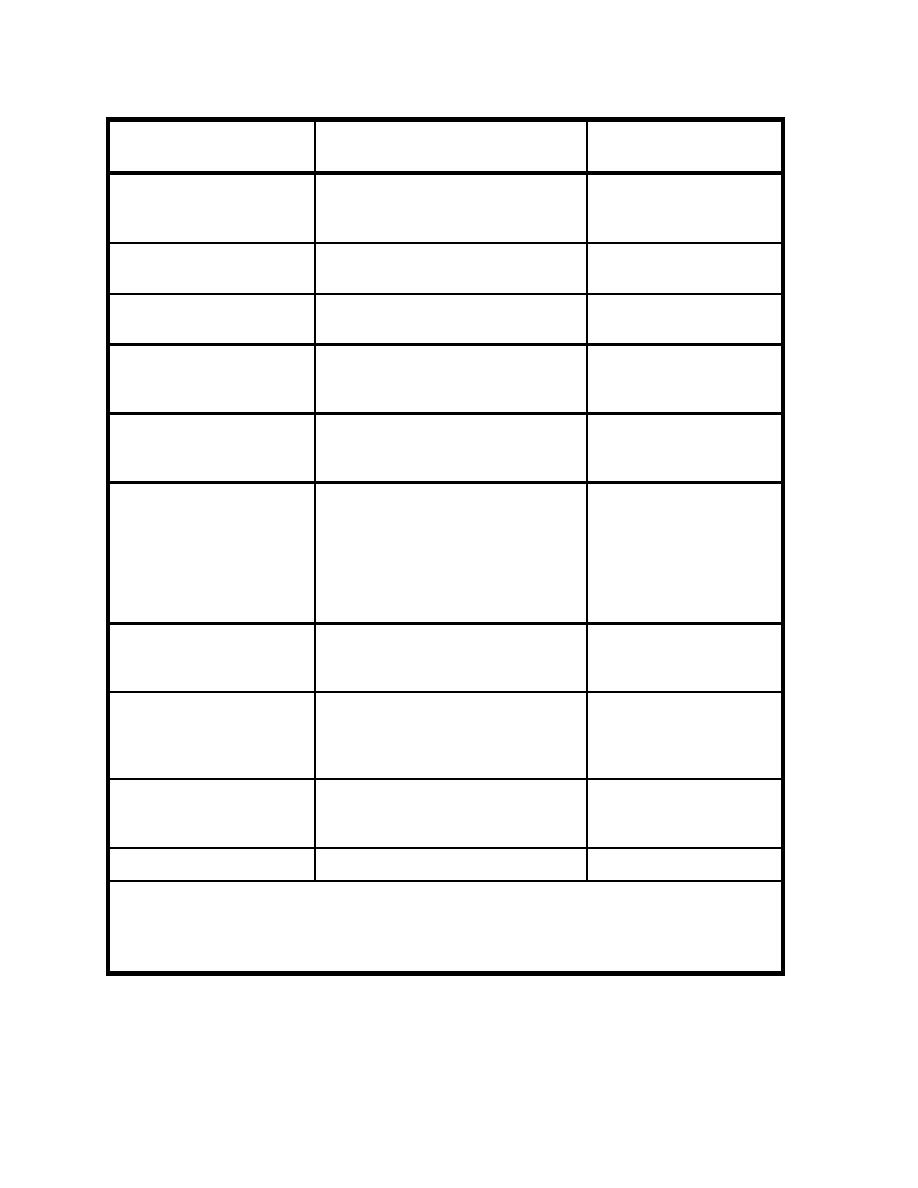

Parameter1,2

Applicability

Typical Design

Conditions2

Typically sized to are 1.5

-Filter Media Acid Wash

Used as required to reduce lime scaling

times the capacity of the

(Subparagraph 2-4.6.3.2)

on filter media for lime conditioning

press.

applications.

-Compressed Air

(Subparagraph 2-4.6.4)

Instrument Air

Used as required for pneumatic control.

Typically requires 690 kPa

pressure.

Air Blow/Core Blow

Used as desired to reduce excessive

filter media washing and provide drier

sludge cake.

690-1380 kPa.

Membrane Air

Typically used with variable-volume

Inflation

presses for no more than 150 psi

pressure applications.

Filter Press Control

Application specific.

Applicable type (i.e., manual,

Systems (Paragraph 2-10)

semiautomatic, and automatic systems)

based on the degree of desired

automation. Typically degree of

automation dependent on size of unit

and use of accessories and auxiliary

systems.

Sludge Cake Handling and

Typically involves only direct discharge

4 days' minimum storage

Storage

into storage container.

required if no other

dewatering facilities exist.

(Paragraph 2-4.10)

Sludge Cake Transport

Application specific.

Typically involves use of either

(Paragraph 2-4.11)

conveyor, auger, or sludge cake

pumping system when further sludge

treatment is required.

Sludge Cake Disposal

Application specific.

Several ultimate disposal methods are

(Paragraph 2-4.12)

available and are dependent on the

specific sludge generated.

1

More details are provided on design considerations and specific applications in the paragraphs

referenced.

2

Conversion Factors:

1 kPa = 0.15 psi

1 kg/m2 = 0.2 lb/ft2

1 L/m2s = 1.45 gpm/ft2

2-4.3.1.1 The feed system should be designed to achieve the initial fill cycle at initial

pressure (typically 70 to 140 kPa [10 to 20 psig]) within the first 5 to 15 minutes to

ensure even sludge cake formation. Any imbalance in the sludge feed rate or cake

formation can result in a nonuniform cake of high resistance, cloth binding, or initial poor

filtration quality, and longer cycle times (EPA 1979). After this initial fill period and as the

2-28

Previous Page

Previous Page