UFC 3-280-03

23 JULY 2003

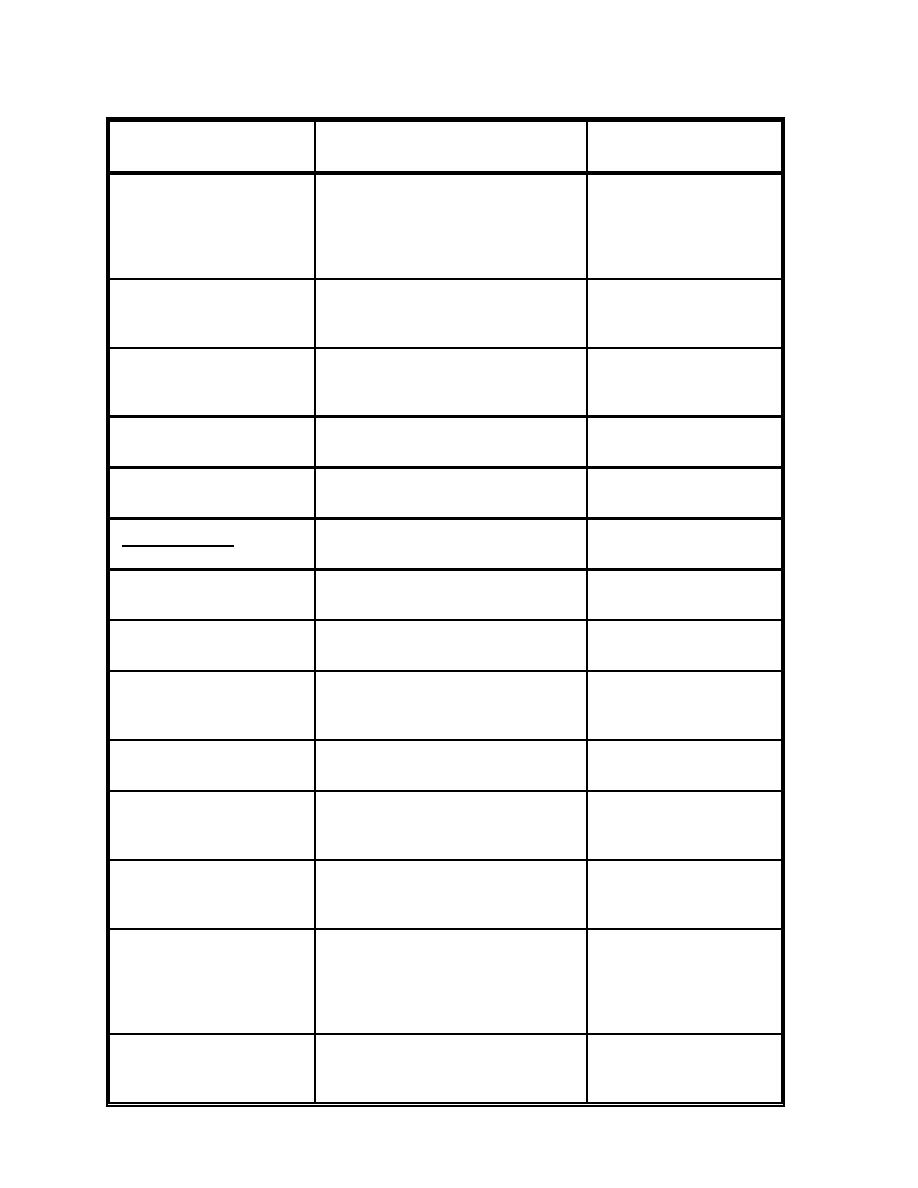

Parameter1,2

Applicability

Typical Design

Conditions2

-Structural Frame

Both side bar and overhead frame types

(Subparagraph 2-4.5.1)

available. Overhead frame typically used

for plate sizes greater than 1200 mm (48

inch) or for higher pressure applications

(i.e., 1550 kPa [225 psi]).

-Filter Press Plates

Size dependent on volume

(Subparagraphs 2-4.5.2 and

of sludge cake generated

2-8.1.2 and Table 2-8)

per cycle.

-Filter Media

(Subparagraphs 2-4.5.3 and

2-8.1.3)

-Closing Mechanism

(Subparagraph 2-4.5.4)

-Plate Shifter

(Subparagraph 2-4.5.5)

Optional Features:

Can be used for either type of press if

(Subparagraph 2-4.5.6)

desired.

-Safety Guards

(Subparagraph 2-4.5.6.1)

-Light Curtains

(Subparagraph 2-4.5.6.2)

-Drip Trays and Bombay

Doors

(Subparagraph 2-4.5.6.3)

-Cake Breakers

(Subparagraph 2-4.5.6.4)

Filter Press Accessories

and Auxiliary Systems

(Paragraph 2-4.6)

Application specific.

-Chemical Feed

As required for chemical conditioning,

(Subparagraph 2-4.6.1)

precoat, and filter media acid wash

systems.

Typically sized to 1.5 times

-Precoat

As required to reduce excessive filter

the press capacity, with an

(Subparagraph 2-4.6.2)

washing requirements for sticky sludge

application rate of 0.4

applications.

kg/m2 over a 3-5 minute

period at 0.2 to 0.3 L/m2s.

10.3 MPa wash pressure

-Filter Media Water Wash

Required for all applications. Both

typical.

(Subparagraph 2-4.6.3.1)

manual and automatic systems

available.

2-27

Previous Page

Previous Page