UFC 3-280-03

23 JULY 2003

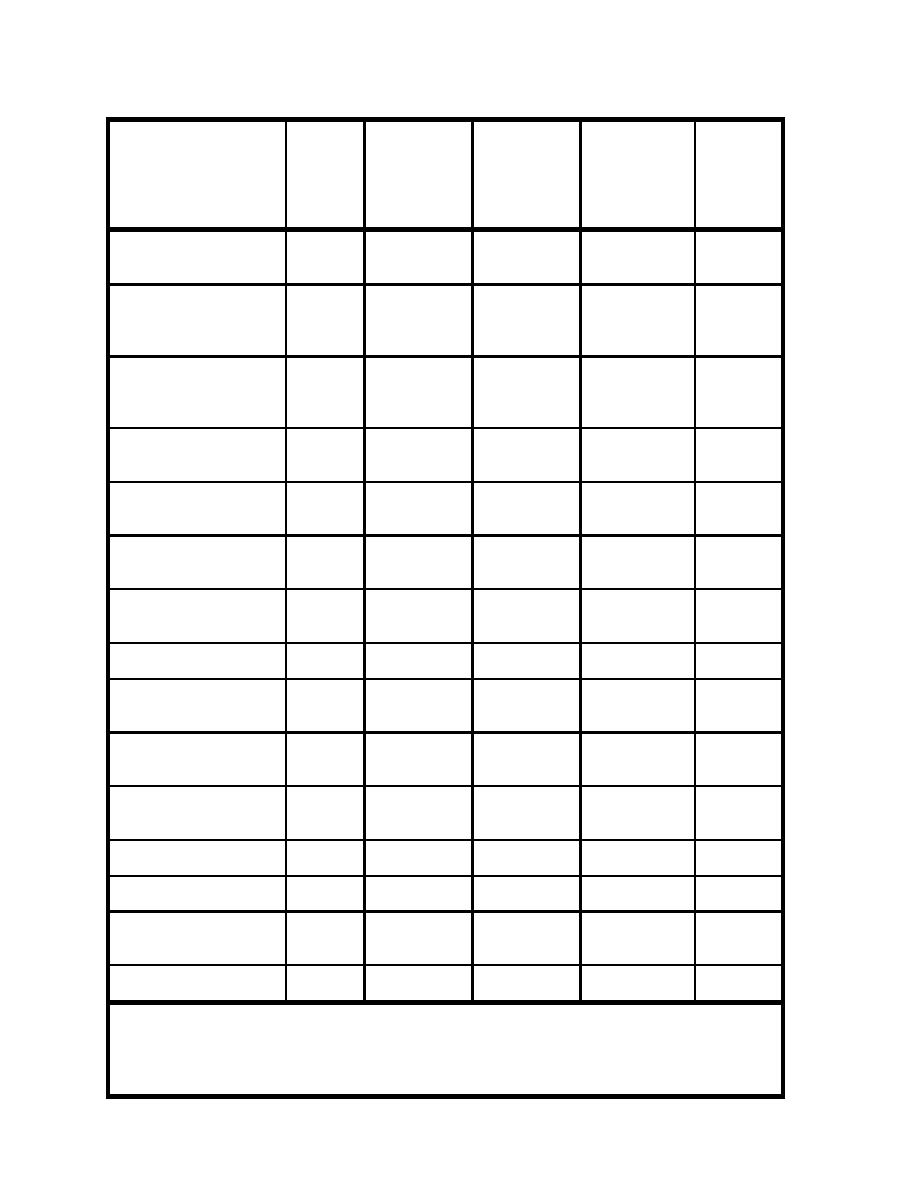

Chemical

Addition-

Feed

Cake

Percent of

Solids

Cycle Time

Pressure

Solids

1

Dry Solids2

(Minutes)3

(kPa)4

Application

(%)

(%)

Municipal Water FeCl3

2 to 8

Polymer

90180

1550

30 to 40

Treated Sludge

60120

1550

35 to 60

Oily Industrial Wastes

4 to 15

Polymer or

FeCl3-5 &

Lime-15

120180

1550

30 to 50

Oily Waste Refinery

4 to 8

FeCl3-10 &

Sludge

Lime-30 or

Lime-30

Pharmaceutical

1 to 4

FeCl3-10 &

150240

1550

25 to 35

Biological Sludge

Lime-30

Surface Water (Low

2 to 3

Polymer or

150180

690 or 1550

30 to 35

Turbidity)

Lime-25

Surface Water (High

4 to 8

Polymer or

90120

690 or 1550

35 to 50

Turbidity)

Lime-15

Surface Water (Lime

6 to 10

None

45120

690

40 to 55

Softened)

Steel Scale

15 to 25

Lime-5

4590

690 or 1550

50 to 70

Textile Waste

2 to 8

FeCl3-10 &

150240

1550

25 to 35

Lime-30

Water Based Ink Sludge

1 to 10

FeCl3-5 &

120210

1550

25 to 55

Lime-15

Water Based Paint

4 to 10

FeCl3-4 &

120180

1550

35 to 60

Sludge

Lime-12

Wet Scrubber

5 to 15

None

4590

690 or 1550

45 to 60

Yttrium Earth

40 to 60

None

1020

690

85 to 95

Zinc Phosphate

1 to 10

None or

60180

690 or 1550

25 to 45

Lime-15

Zinc Sterate

5 to 10

None

2060

690

30 to 40

1

Application data complied from manufacturers referenced in Appendix A.

2

Polymer dosages are not listed because several types may be commercially available and applicable for

the sludge application listed.

3

Cycle time includes mechanical turnaround (i.e., plate shifting, etc.).

4

Pressure conversations: 690 kPa is equivalent to 100 psi, and 1550 kPa is equivalent to 225 psi.

2-21

Previous Page

Previous Page