UFC 3-280-03

23 JULY 2003

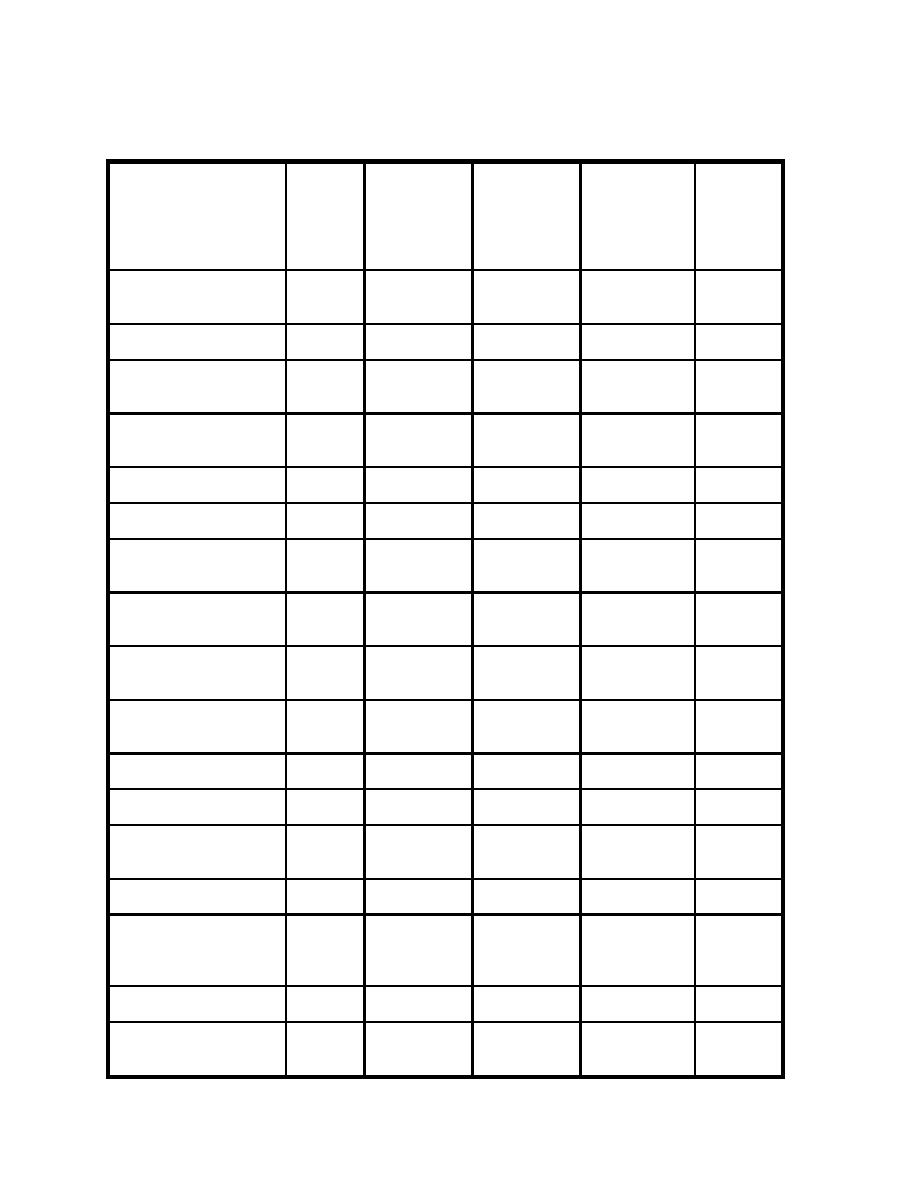

Table 2-4 Typical sludge dewatering performance data fixed-volume filter press.

Chemical

Addition-

Feed

Cake

Percent of

Solids

Cycle Time

Pressure

Solids

1

Dry Solids2

(Minutes)3

(kPa)4

Application

(%)

(%)

Aluminum Hydroxide

1 to 10

None or

120240

690 or 1550

25 to 35

Polymer

Barium Titanium Dioxide

40 to 50

None

6090

690 or 1550

60 to 80

Brewery Grain Mash

2 to 10

Polymer or

120210

690 or 1550

25 to 40

Lime-15

Calcium or

4 to 10

None or

90150

690 or 1550

30 to 60

Tri-Calcium Phosphate

Lime-25

Cement Slurry

60 to 70

None

2060

690

80 to 90

Ceramic Clay Slurry

20 to 30

None

60120

1550

60 to 80

Ceramic Wash Down

2 to 6

None or

90240

1550

30 to 45

Sludge

Polymer

Chicken Processing

2 to 8

FeCl3-6 &

90150

1550

30 to 40

Waste

Lime-18

Chrome Hydroxide

2 to 6

None or

150240

690 or 1550

25 to 35

Polymer

Coal Pile

4 to 8

Lime-10

90120

690

30 to 40

Runoff

Coal Slurry

25 to 40

None

4590

690

60 to 80

Cooling Tower Blowdown

4 to 8

Lime-10

90120

690

30 to 40

Copper Hydroxide

1 to 6

None or

120240

690 or 1550

25 to 40

Polymer

Creosote Waste

2 to 8

Lime-30

120180

1550

30 to 40

60210

1550

30 to 50

Domestic Septic Sludge

1 to 10

FeCl3-5 &

Lime-15 or

Lime-15

Fine Ash

6 to 10

None

60120

690 or 1550

40 to 60

Flue Gas Desulfurization

15 to 30

None

3090

690 or 1550

40 to 60

Oxidized Sludge

2-19

Previous Page

Previous Page