UFC 3-280-03

23 JULY 2003

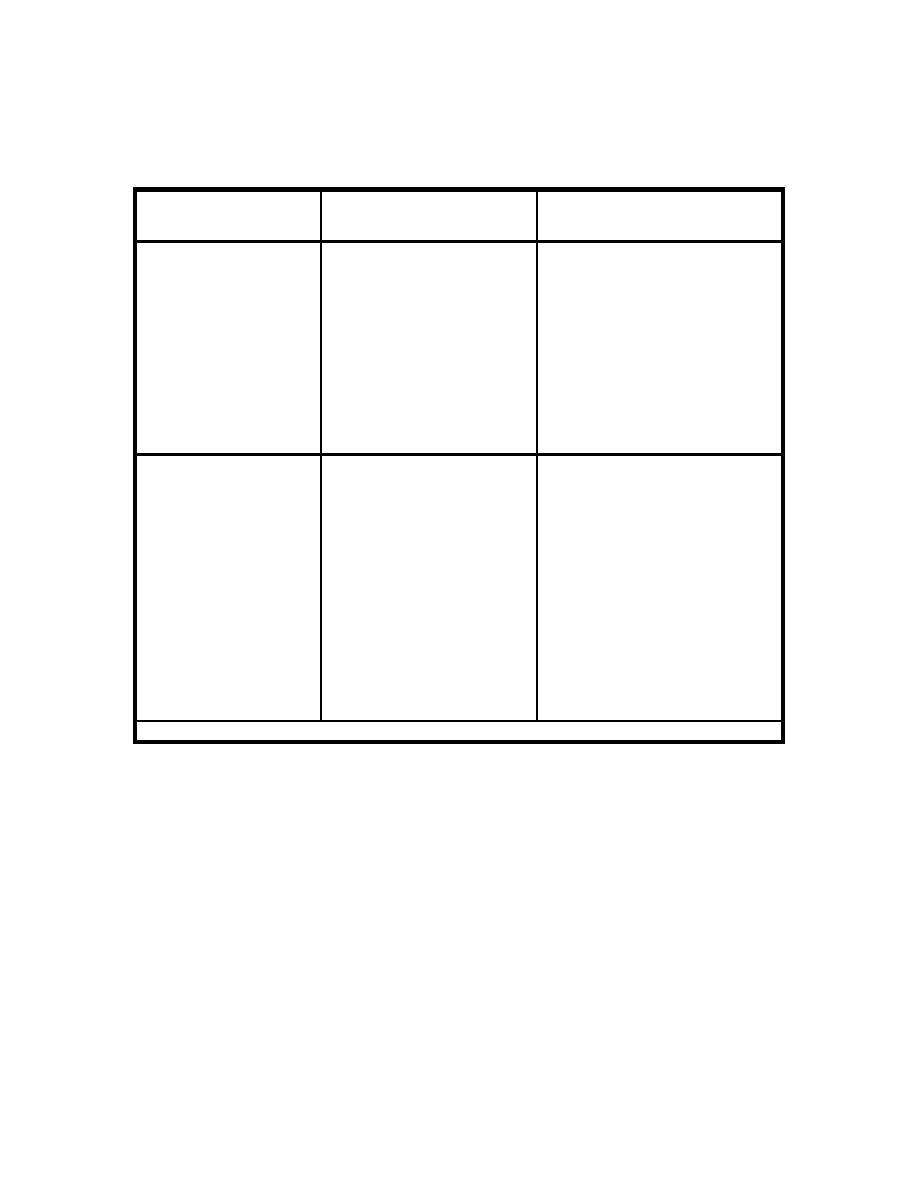

Table 2-3. Advantages and disadvantages of fixed-volume versus

variable-volume filter presses.

Type of Dewatering

Advantages

Disadvantages

Process/Device

Dewaters only well conditioned

Fixed-Volume Press

Higher volumetric capacity

sludges.

requires fewer dewatering

cycles per day.

More chemicals required for

conditioning.

Less complex instrumentation.

Longer cycle time/per unit volume of

Fewer moving parts.

sludge.

Longer plate life.

Lower maintenance.

Limited volumetric capacity, requires

Variable-Volume Press

Dewaters marginally

more cycles per day.

conditioned sludges.

Mechanically complex.

Shorter cycle time.

Complex instrumentation.

Fewer chemicals required for

conditioning.

Labor intensive filter cloth

replacement.

Lower operation and

maintenance for sludge feed

Higher maintenance.

pumps.

Precoating system is not

required.

Source: EPA (1982a, 1986)

2-3.2.1 Advantages. As shown in Table 2-2, plate and frame filter presses have

several advantages compared with other sludge dewatering systems. A high cake solids

content (typically 30 to 50%) can be achieved, which is 6 to 10% higher than that

achieved with other dewatering systems. A very high solids capture (98%) can be

obtained. High filtrate quality can be achieved, which lowers recycle stream treatment

requirements. This system can dewater hard-to-dewater sludge and sludge of varying

characteristics and is mechanically reliable. In addition, this type of system may be the

only one capable of dewatering sludge dry enough to meet landfill requirements in some

areas.

As shown in Table 2-3, the variable-volume press system has several advan-

tages over the fixed-volume press system. First, the variable-volume system produces a

dryer cake (typically 3 to 5%) of more uniform moisture content. Second, the variable-

volume press has a shorter cycle time and, thus, a higher production throughput. This

shorter cycle time is a result of the more effective and uniform pressure placed on the

sludge during the dewatering process. Other advantages of the variable-volume filter

2-14

Previous Page

Previous Page