TM 5-623

Name of Distress:

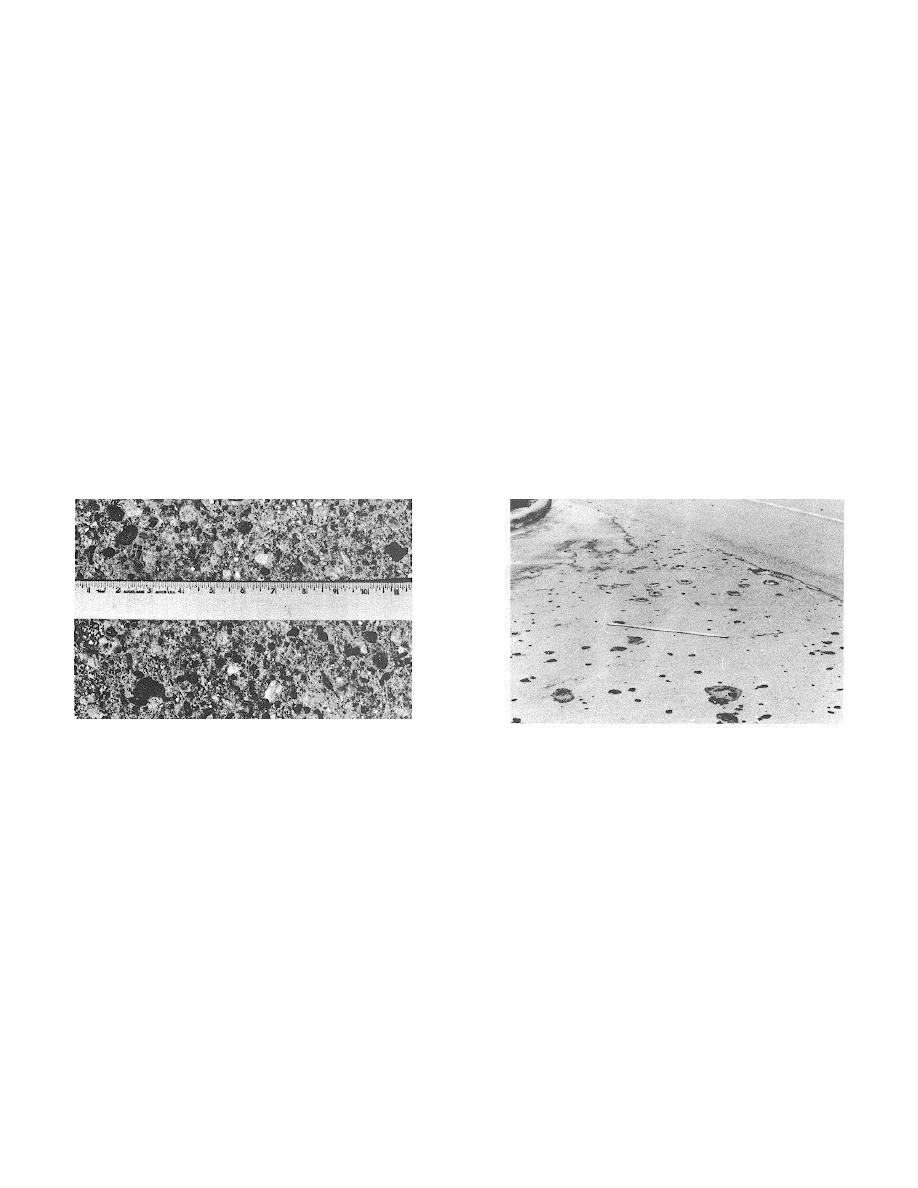

Polished Aggregate.

Description:

This distress is caused by repeated traffic applications. When the aggregate in

the surface becomes smooth to the touch, adhesion with vehicle tires is

considerably reduced. When the portion of aggregate extending above the

surface is small, the pavement texture does not significantly contribute to

reducing vehicle speed. Polished aggregate should be counted when close

examination reveals that the aggregate extending above the concrete is

negligible, and the surface aggregate is smooth to the touch.

This type of distress is indicated when the number on a skid resistance test is low

or has dropped significantly from previous ratings.

Severity Levels:

No degrees of severity are defined. However, the degree of polishing should be

significant before it is included in the condition survey and rated as a defect

(fig B-116).

How to Count:

A slab with polished aggregate is counted as one slab.

Name of Distress:

Popouts.

Description:

A popout is a small piece of pavement that freeze-thaw action, combined with

aggregate expansion, causes to break loose from the surface. Popouts

usually range in diameter from approximately 1 to 4 inches and in depth from

M to 2 inches.

Severity Levels:

No degrees of severity are defined for popouts. However, popouts must be

extensive before they are counted as a distress. Average popout density

must exceed approximately three popouts per square yard over the entire

slab area (fig B-117).

Figure B-116. Polished aggregate.

Figure B-117. Popouts.

How to Count:

The density of the distress must be measured. If there is any doubt that the

average is greater than three popouts per square yard, at least three random

1-square-yard areas should be checked. When the average is greater than

this density, the slab should be counted.

Name of Distress:

Pumping.

Description:

Pumping is the ejection of material from the slab foundation through joints or

cracks. This is caused by deflection of the slab by passing loads. As a load

moves across the joint between the slabs, water is first forced under the

leading slab, and then forced back under the trailing slab.

This erodes and eventually removes soil particles, resulting in progressive loss of

pavement support. Pumping can be identified by surface stains and evidence

of base or subgrade material on the pavement close to joints or cracks.

Pumping near joints is caused by poor joint sealer and indicates loss of

support; repeated loading will eventually produce cracks. Pumping can also

occur along the slab edge, causing loss of support.

B-41

Previous Page

Previous Page