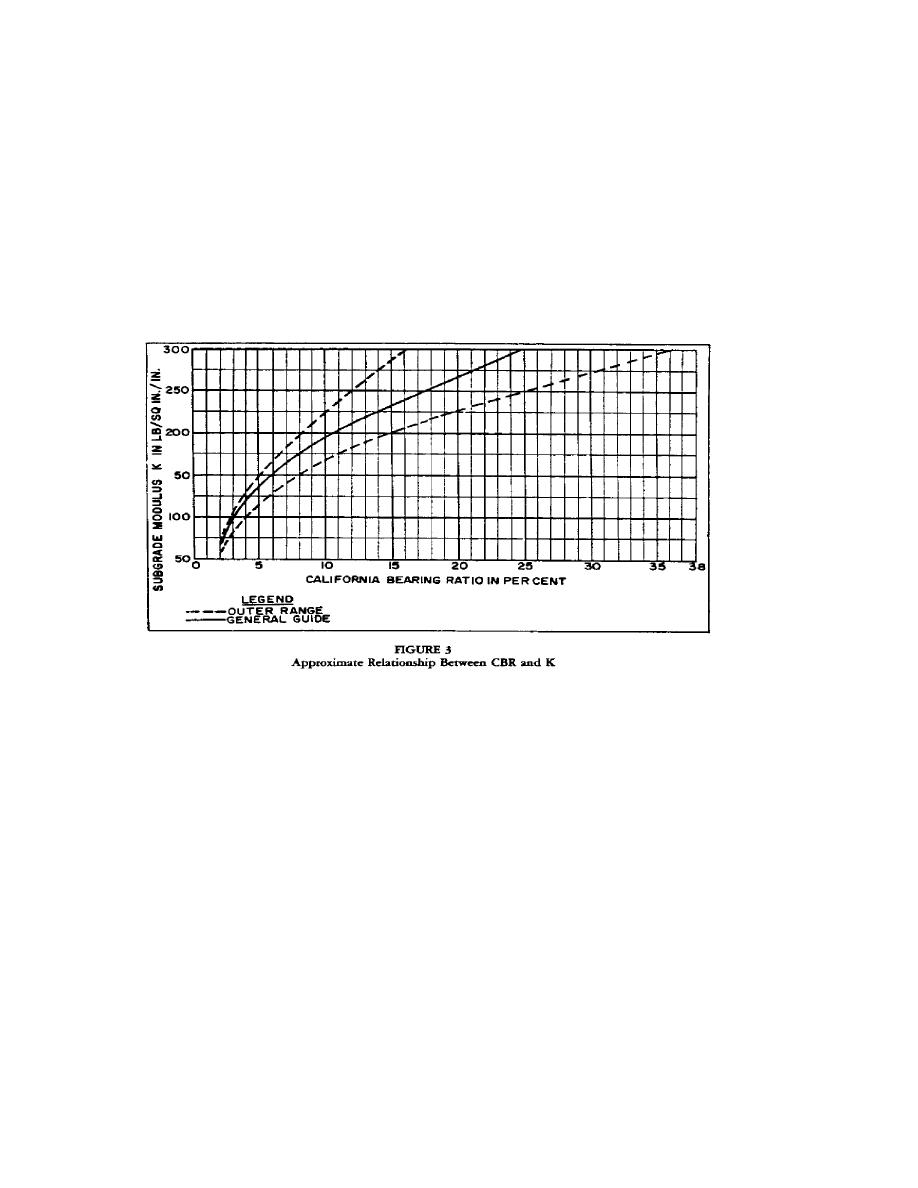

d. Subgrade Modulus. The modulus of subgrade reaction (K) is the unit

load per inch of deflection on a 30-inch-diameter rigid steel plate. Determine

the subgrade modulus when designing rigid pavements. Use the test procedure

given in ASTM D1196 and compute the K value at the unit load corresponding to

.05 inches deflection. For an estimation of K from CBR test results, see the

relationship given by Figure 3.

e. Frost Susceptibility. As a general rule, inorganic soils containing

greater than 3 percent by weight finer than .02 millimeters are frost

susceptible. Where frost-susceptible soils arc encountered in regions of

freezing temperatures, design pavements to limit the depth of frost

penetration into the subgrade. For a specific design procedure, see

Airfield Pavement, NAVFAC DM-21.

7. BORROW MATERIAL. From the developed soil profiles, determine the quality of

material available for fill.

a. Fill Material. Soil types shown in Table 2 are listed in decreasing

order of their value as fill material. Generally, granular soils are the

preferred fill material and should bc used in the top of the subgrade. Avoid

the use of expansive clays and organic soils.

b. Borrow. When borrow is required, locate pits in proximity to the

proposed roadway using soil maps and other forms of exploration. To determine

the suitability and extent of borrow material, conduct borings in a grid

pattern on approximately 100-foot centers. The depth of borings should be 2 to

4 feet below the anticipated depth of borrow.

8

Previous Page

Previous Page