TM

5-822-14/AFJMAN

32-1019

spreading should be completed in the first working

2 WINDROWS

lane and under way in the second lane before

mixing operations are begun. This ensures a full-

width cement spread without a gap between lanes

3 WINDROWS

and keeps spreading equipment out of the way of

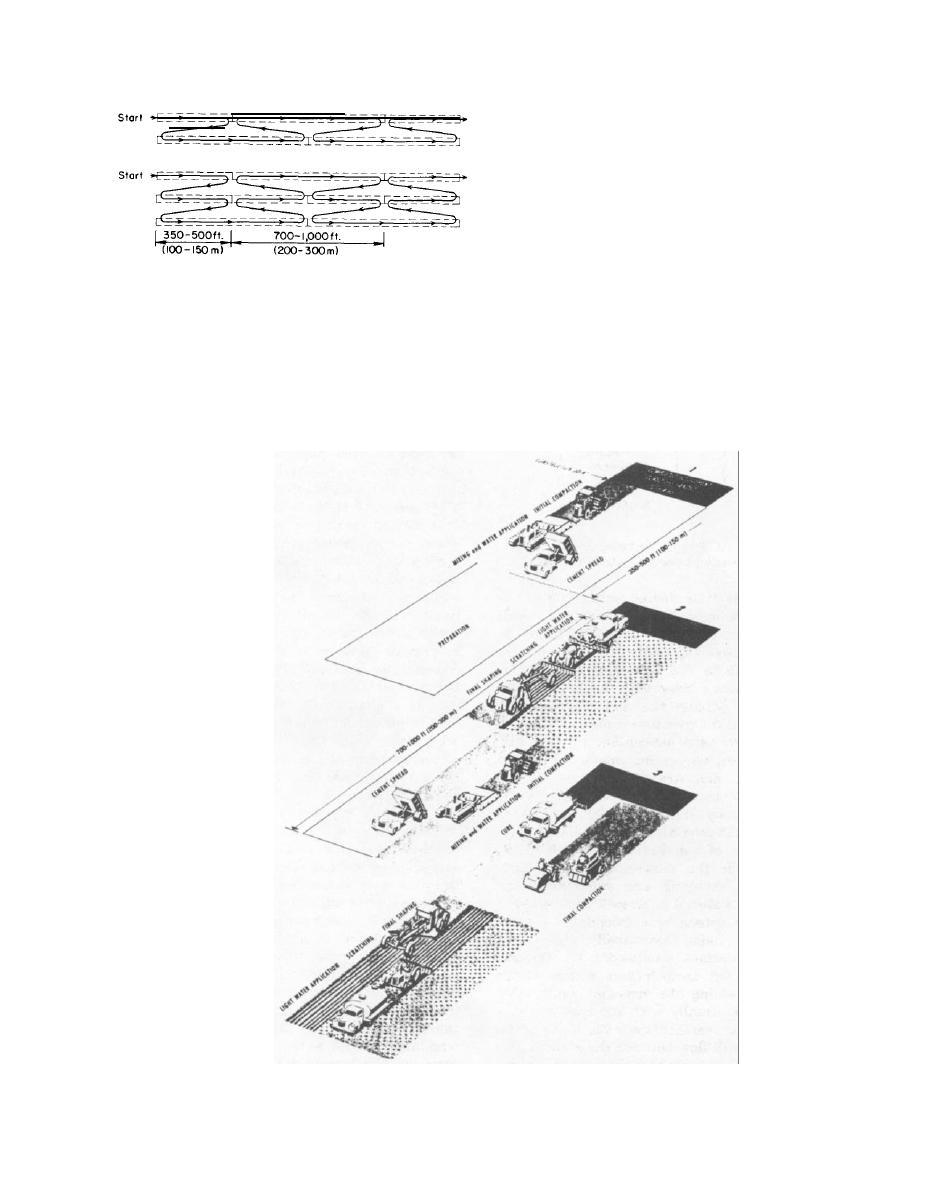

mixing equipment. See figures 4-12 and 4-13 for

an illustration of the construction sequence.

3. Single-shaft traveling mixing machine.

Soil-cement construction with single-shaft travel-

ing mixers differs from the preceding examples in

Figure 4-11. Plan for processing with windrow-type

that more than one mixing pass is required. The

traveling pugmill.

basic principles and objectives are the same, how-

ever. Shaping, scarifying, and pulverizing the

to approximate crown and grade. If an old roadbed

roadway are the first steps of preparation, as

is extremely hard and dense, prewetting and scari-

described previously in this chapter. Since most

fication will facilitate processing. Processing is

single-shaft traveling mixers were not designed to

done in lanes 350 to 500 feet long and as wide as

scarify, the soil material may need to be loosened

the mixing machine. Cement is spread on the soil

with a scarifier. Prewetting the soil material is

material in front of the mixing machine. Cement

common practice. Applying water at this stage of

Figure 4-12. Sketch of soil-cement processing operations with multiple-transverse-shaft traveling mixing machine.

4-6

Previous Page

Previous Page