TM

5-822-14/AFJMAN

32-1019

the tank trucks are being switched. As soon as the

point water is added through spray nozzles and the

first windrow is mixed and spread on one section

remaining paddles complete the mixing. A strike-

of the roadway, it is compacted. At the same time

off attached to the mixing machine spreads the

a second windrow is being mixed and spread. It in

mixed soil-cement. If a motor grader is used to

turn is then compacted. Finishing of the entire

spread the mixture and a tamping roller is used

roadway is completed in one operation. Water

for compaction, the mixture should first be loos-

requirements are based on the quantity of soil

ened to ready it for compaction. If two windrows

material and cement per unit length of windrow.

have been made, the mixing machine progresses

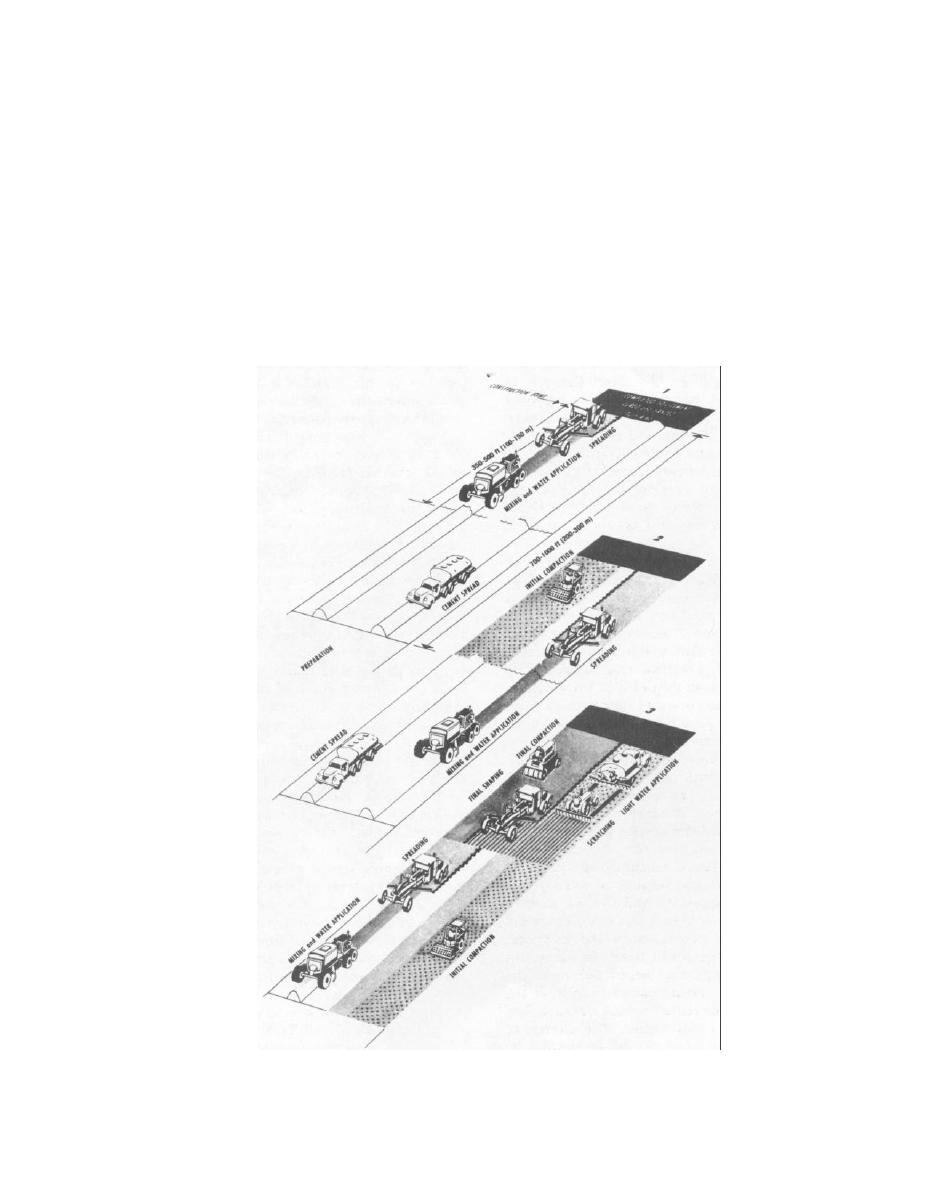

See figures 4-10 and 4-11 for construction se-

350 to 500 feet along one windrow and then is

quences for windrow-type operations.

backed up to process the other windrow for 700 to

2. Multishaft traveling mixing machine.

1,000 feet. The cement spreading operation is kept

Since most multi-shaft traveling mixing machines

just ahead of the mixing operation. Water is

have a high-speed pulverizing rotor, preliminary

supplied by tank trucks. A water tank installed on

pulverization is usually unnecessary. The only

preparation required is shaping the soil material

the mixer will permit continuous operation while

Figure 4-10. Sketch of soil-cement processing operations with windrow-type traveling pugmill.

4-5

Previous Page

Previous Page