TM 5-822-13/AFJMAN 32-1018

Stabilization with portland cement, lime, flyash, or other agent that causes a chemical cementation to occur shall

be referred to as chemical stabilization. Chemically treated soils having unconfined compressive strengths greater

than the minimum strength are considered to be stabilized materials and should be tested in accordance with the

methods specified for stabilized materials. Chemically treated soils having unconfined compressive strengths

less than the minimum strength are considered to be modified soils. Most likely this will result in using the

maximum allowable subgrade modulus. Bituminous-stabilized materials should be characterized in the same

manner as bituminous concrete. Stabilized materials other than bituminous stabilized should be characterized

using cracked section criteria, which is explained later in conjunction with figure 4-3.

(a) Stabilized materials for the base and subbase must meet the strength and durability requirement of

TM 5-822-14/AFJMAN 32-1018. The basic strength requirements are presented in table 4-1.

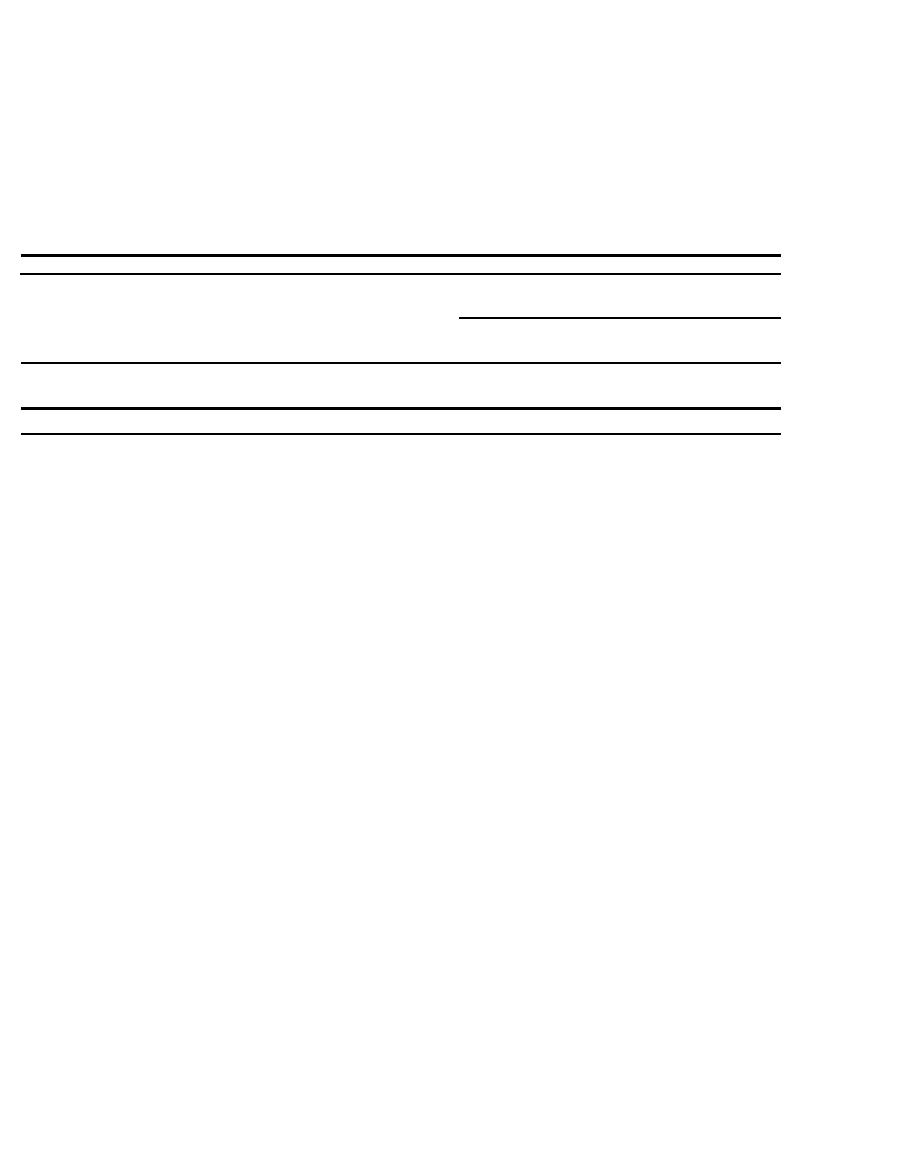

Table 4-1. Minimum Unconfined Compressive Strengths for Cement, Lime, and Combined Lime-Cement Flyash Stabilized Soils.

Minimum Unconfined Compressive Strength,*

pounds per square inch

Concrete

Flexible

Pavement

Pavement

Stabilized Soil Layer

750

500

Base Course

250

200

Subbase course, select material, or subgrade

*Unconfined compressive strength determined at 7 days for cement stabilization and 28 days for lime or lime-cement-flyash stabilization.

(b) Lime-stabilized materials will continue to gain strength with time; therefore, if sufficient evidence is

available that indicates a lime-stabilized material will acquire adequate strength prior to traffic, then the 28-day

strength requirement may be waived.

(c) For concrete pavements having a stabilized base or subbase, the determination of elastic modulus

values becomes more complicated than for the pavement with unbound granular base. Two cases in particular

should be considered. In the first case, where the stabilized layer is considered to be continuous with cracking

due only to curing and temperature, the elastic modulus values may be determined from flexural beam tests. In

the second case, the stabilized layer is considered cracked because of load. Once the cracks have developed

extensively in the stabilized base, the layer would behave as a granular material but with a higher modulus

value. The cracked stabilized base course is represented by a reduced resilient modulus value, which is deter-

mined from the relationship between resilient modulus and unconfined compressive strength shown in figure

4-3. This relationship may be used for concrete pavement design for roads and streets.

(d) The general, material, and compaction requirements of base courses under a pavement are described

in TM 5-822-5/AFM 88-7, Chap. 3.

(5) Subgrade soils. The term "subgrade" as used herein refers to the natural, processed, or fill soil founda-

tion not meeting the requirements for a base or subbase on which a pavement structure is placed. The modulus

of the subgrade is determined through the use of the repetitive triaxial test. The procedure is described in TM 5-

825-2-1/AFM 88-6, Chap. 2, Section A. For most subgrade soils, the modulus is greatly affected by changes in

moisture content and state of stress. As a result of normal moisture migration, water table fluctuation, and other

factors, the moisture content of the subgrade soil can increase and approach saturation with only a slight change

in density. Since the strength and stiffness of fine-grained materials are particularly affected by such an increase

in moisture content, these soils should be tested in the near-saturation state.

(a) Procedures for specimen preparation, testing, and interpretation of test results for cohesive and

granular subgrades are presented in TM 5-825-2-1/AFM 88-6, Chap. 2, Section A. For the layered elastic theory

of flexible pavement design, the maximum allowable modulus for a subgrade soil should be restricted to 30,000

pounds per square inch (psi).

(b) In areas where the subgrade is to be subjected to freeze-thaw cycles, the subgrade modulus must be

determined during the thaw-weakened state. Testing soils subject to freeze-thaw requires specialized test appa-

ratus and procedures. The Cold Regions Research and Engineering Laboratories (CRREL) can assist in charac-

terizing subgrade soils subjected to freeze-thaw.

(c) For some design situations, estimating the resilient modulus of the subgrade (M,) based on

available information may be necessary when conducting the repetitive load triaxial tests. An estimate of

the resilient modulus can be made from the relationship of MR = 1500 l CBR, where CBR is the California

Bearing Ratio. This relationship provides a method for checking the reasonableness of the laboratory re-

sults. The relationship shown in figure 4-4 may be used to estimate the elastic modulus from the modulus of

4-4

Previous Page

Previous Page