TM 5-822-13/AFJMAN 32-1018

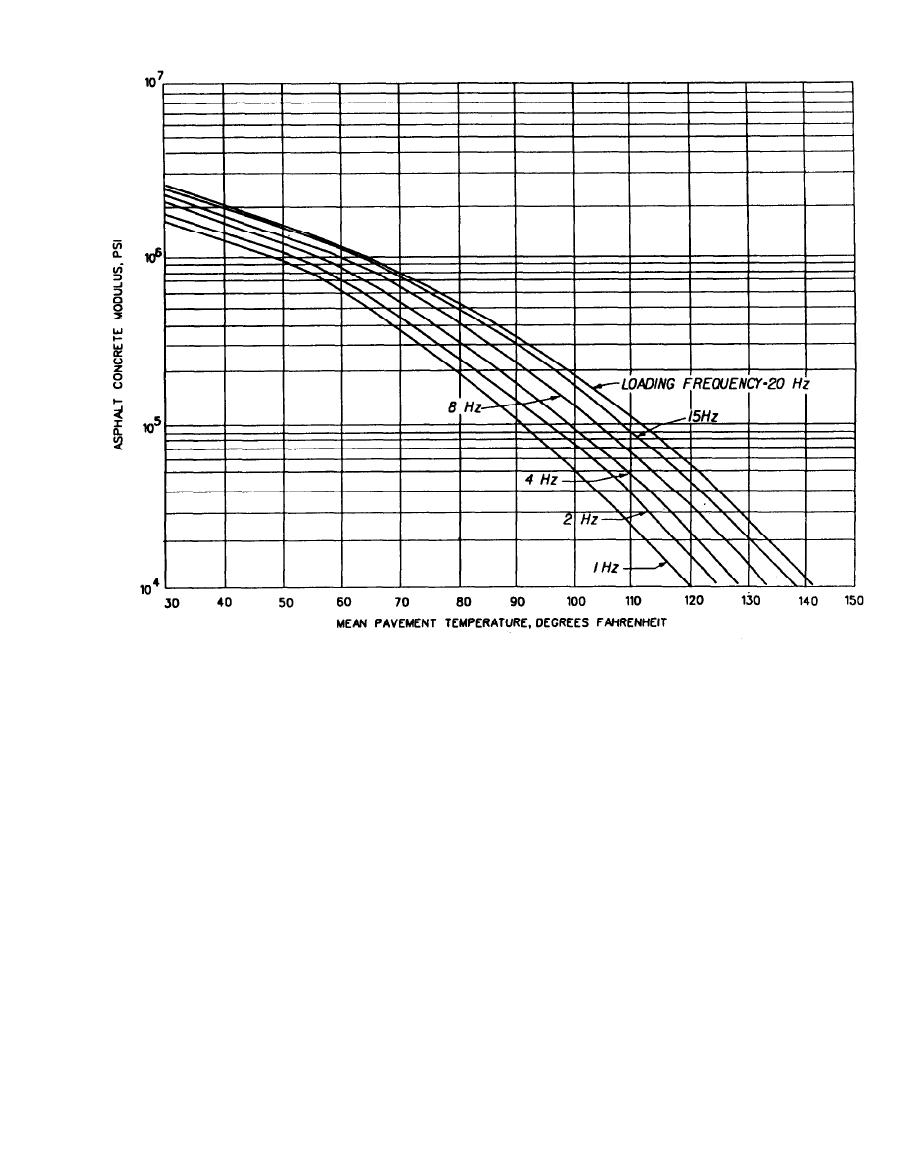

Figure 4-2. Prediction of Asphalt Concrete Modulus for Bituminous Layers.

these extreme ranges, if possible. The modulus value to be used for each strain computation would be the value

applicable for the specific pavement temperature determined from the climatic data.

(b) An indirect method of obtaining an estimated modulus value for bituminous concrete is presented in

detail in TM 5-825-2-1/AFM 88-6, Chap. 2, Section A. Use of this method requires that the ring-and-ball soften-

ing point and the penetration of the bitumen as well as the volume concentration of the aggregate and percent

air voids of the compacted mixture be determined. The modulus of bituminous concrete may also be estimated

from the design pavement temperature using figure 4-2.

(2) Portland cement concrete (PCC). The modulus of elasticity and flexural strength of PCC will be deter-

mined from static flexural beam tests in accordance with ASTM C 78. When test results are not available, a

modulus value of 4,000,000 psi may be assumed for the concrete. Proportioning of the concrete mix and control of

the concrete for pavement construction will be in accordance with TM 5-822-7/AFM 88-6, Chap. 8.

(3) Unbound granular base and subbase course materials. The terms "unbound granular base course

material" and "unbound granular subbase course material" as used herein refer to materials meeting grading

requirements and other requirements for base and subbase for roads and streets, respectively. These materials

are characterized by use of a chart in which the modulus is a function of the underlying layer and the layer

thickness. The chart and the procedure for use of the chart are given in appendix B. The modulus values of

unbound granular bases may also be determined from cyclic triaxial tests on prepared samples. The recom-

mended test procedure is outlined in TM 5-825-3-1/AFM 88-6, Chap. 3, Section A. The base course under a rigid

pavement can be unbound granular or a chemically stabilized material. Design using stabilized materials is de-

scribed in the next section.

(4) Stabilized material. The term "stabilized material" as used herein refers to soil treated with such

agents as bitumen, portland cement, slaked or hydrated lime, and flyash or a combination of such agents to

obtain a substantial increase in the strength of the material over the material's untreated natural strength.

4-3

Previous Page

Previous Page