TM 5-822-11/AFP 88-6, Chap. 7

with carbide tipped bits, chip and damage PCC

b. Initial inspection. After the initial sawing to

pavements.

control cracking of the concrete, the saw cuts

g. Handtools. Enough handtools should be on

should be inspected for spalling. Excessive

hand to allow for work to continue in areas where

spalling of new concrete should not be found in

mechanized equipment cannot be used during the

normal construction. Spalls that extend more than

preparation of the joint or crack. This equipment

1/4 inch horizontally from the sidewall of the

can be straight or hooked bars with chisel shaped

initial cut should be repaired, since normally they

ends. Extra care must be used to ensure the

would not be removed during the widening

concrete is not damaged.

operation. Void areas caused by honeycombing of

h. Power Brooms. A vacuum type power broom

the concrete must also be patched to provide a

should be present to keep the pavement surface

solid joint sidewall for the sealant to bond.

free from all debris. A typical unit is shown in

c. Sawing Reservoir. After the required curing

figure 4-9.

period, the initial saw cut for crack control must

be widened to the size joint specified in the project

4-2.

Preparing New Joints in PCC.

specifications using a self-propelled concrete saw.

a. Initial Sawing. New PCC slabs will have

The depth of the cut should be uniform, and the

joints sawed or formed while the concrete is green

width should not vary along the length of the

(after it has taken initial set) to control cracking.

joint. A freshly sawn joint is shown in figure 4-

Concrete that cracks before the initial sawing must

11.

not be sawed. Instead, the resulting crack must be

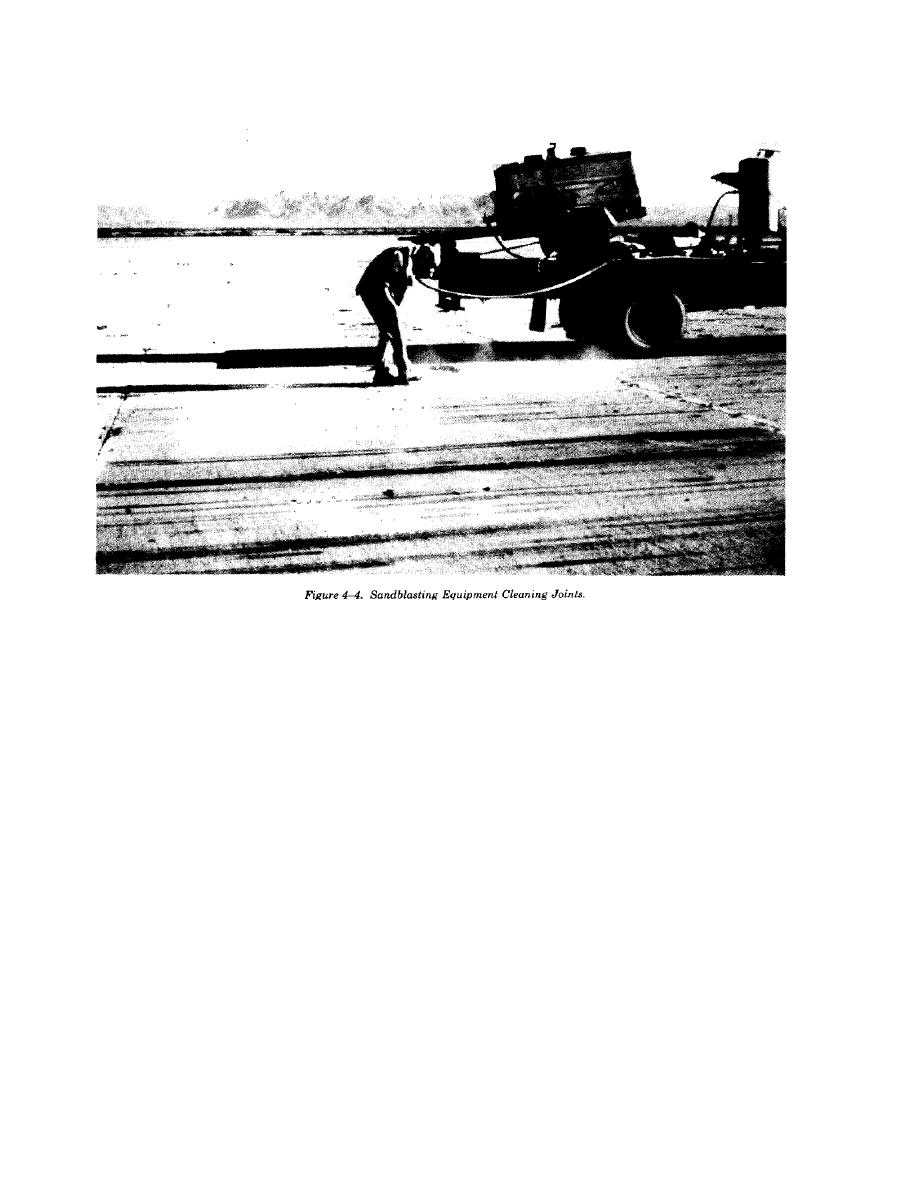

d. Cleaning. Following the sawing operation,

prepared and sealed. The initial cuts or dummy

the joint should be sandblasted to remove laitance,

joints must be prepared to function as a joint. This

curing compound, sawing dust, and other foreign

preparation begins after the curing period of the

debris from the joint sidewalls and from the

concrete has ended. Figure 4-10 provides the

pavement surface adjacent to the joint to a width

sawing sequence in new concrete.

of approximately 1 to 2 inches. A multiple pass

4-4

Previous Page

Previous Page