UFC 3-240-13FN

25 May 2005

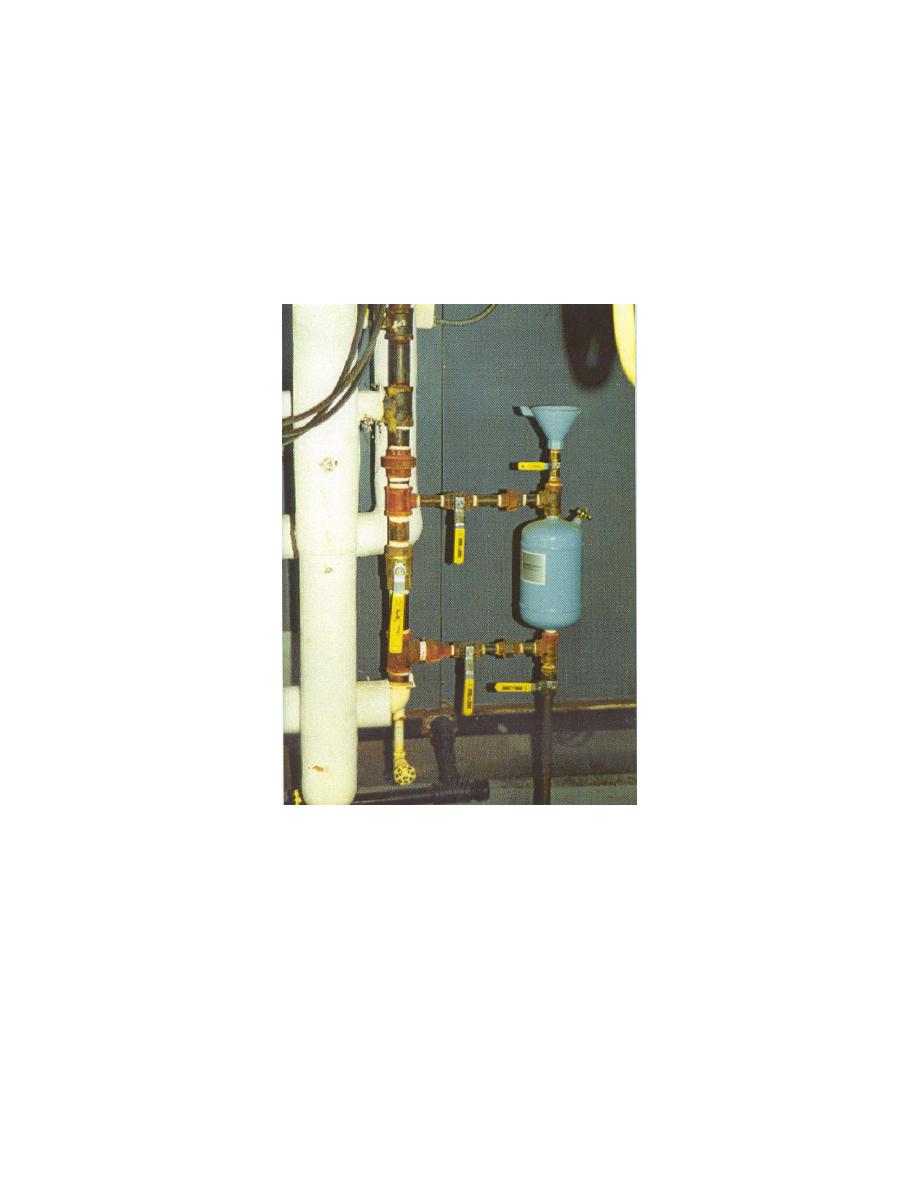

sidestream using a three-valve bypass configuration. Feeders may have funnels or

screw caps. The overall volume of a water treatment system should be considered

when determining the proper size of a pot feeder. A 3.78-liter (1-gallon) pot feeder on a

75,700-liter (20,000-gallon) closed system can work, but is not practical. A larger 18.9-

liter (5-gallon) pot feeder is more practical. Some pot feeders are designed to serve a

dual purpose as a filter.

Figure 7-1. Chemical Pot Feeder

7-2.1.2

Dry Chemical Feeders. Small cooling towers often require a dry,

granular, or pelletized product for control of scale, corrosion, or microbiological

organisms. The dry chemical can be placed in a plastic mesh bag and hung in the

cooling tower sump or put into a plastic container having small holes through which a

stream of water can pass. Small cooling towers can be shock-fed with a liquid chemical

agent, such as a biocide. This practice is not efficient and may be ineffective. The

manual handling of biocides also raises safety concerns. A liquid chemical feed system

may be more effective.

7-2.2

Automatic Chemical Feed with Manual Preparation. This type of feed

system is commonly found on steam boilers for which an operator must physically

prepare a chemical mixture specific for that boiler operation. After preparation, the

chemical mixture is automatically fed on demand using a chemical pump that is

174

Previous Page

Previous Page