UFC 3-240-13FN

25 May 2005

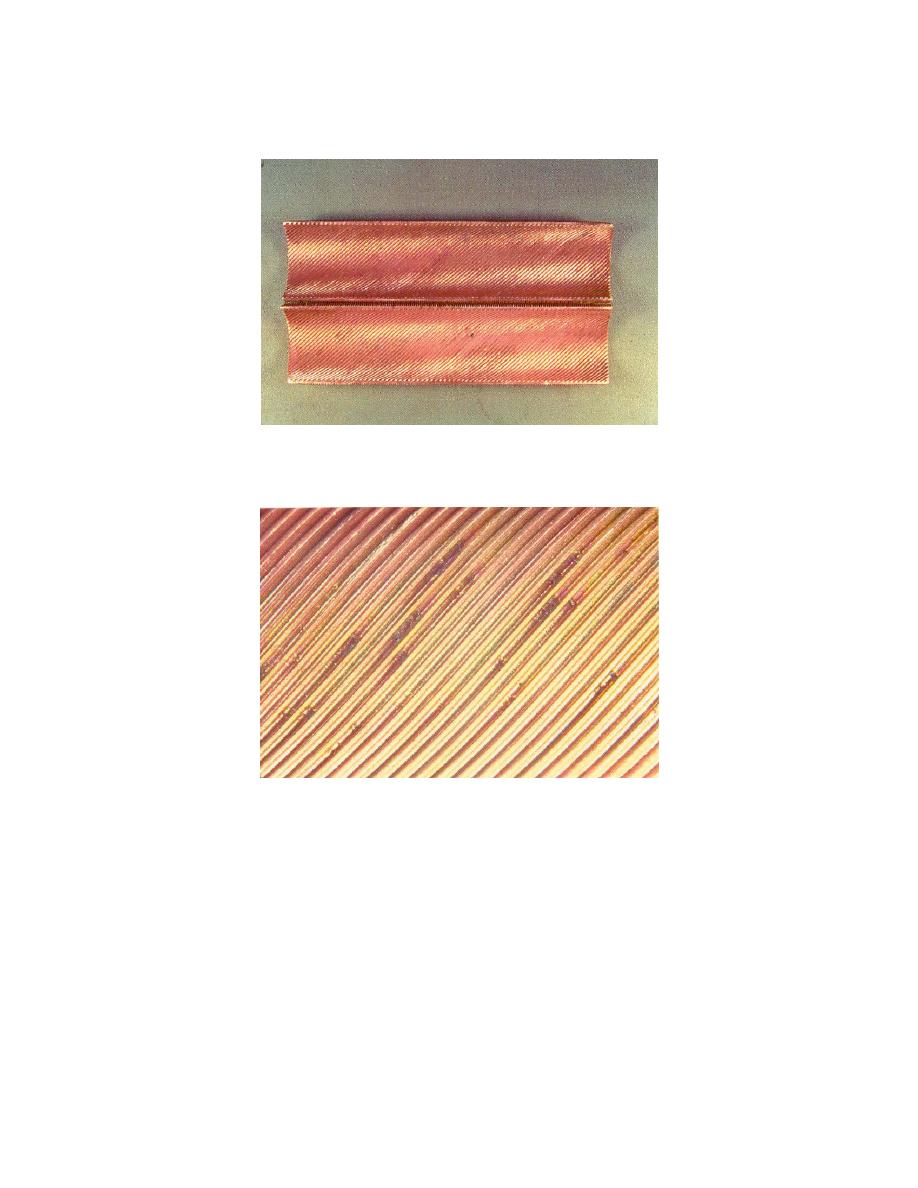

Figure 4-12. Super-Enhanced Copper Tubes

Figure 4-13. Close-Up of Corrosion Pitting on Super-Enhanced Copper Tube

4-1.5.2

White Rust. Some cooling towers are constructed with galvanized steel

components and must not be exposed to conditions of high pH (high alkalinity). The

galvanizing process deposits a protective zinc coating on a mild steel metal surface,

resulting in increased resistance to corrosion. Failure to avoid such exposure can result

in production of "white rust" due to the corrosion of the galvanizing coating. Eventually,

this corrosion process exposes the mild steel underneath, which then starts to corrode.

White rust failures have been a common occurrence throughout the country, mainly with

newer cooling towers. Proper protection of the galvanizing material is necessary both

during startup of a new cooling tower and during normal operations. Specific water

treatment chemicals are needed to provide this protection. Examples include

pretreatment with a high level of orthophosphate.

4-1.5.3

Cooling Tower Film Fill. Small- and medium-sized cooling towers use

film fill, which is a tightly packed media as compared to the splash-type fill used

100

Previous Page

Previous Page