UFC 3-240-13FN

25 May 2005

4-1.4.3

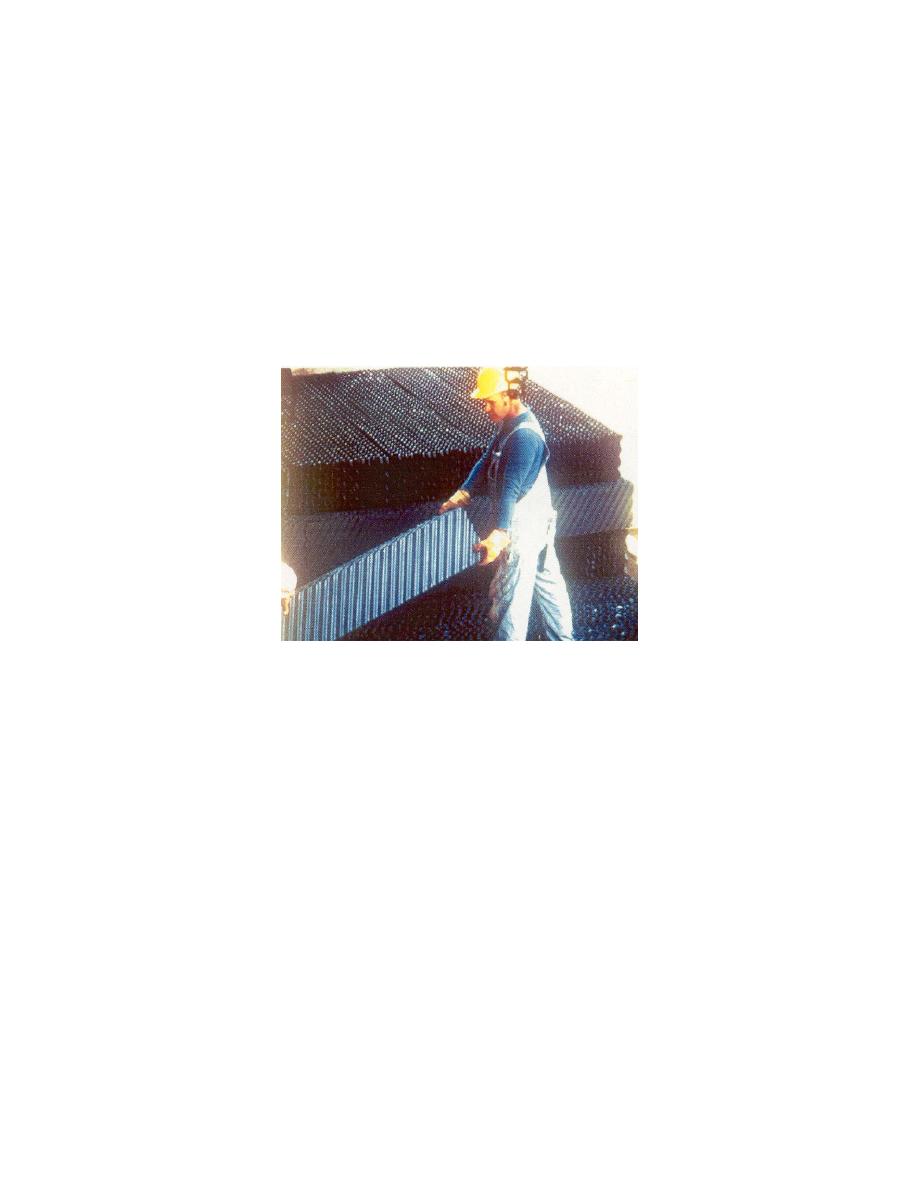

Fill. Fill is the internal part of a tower where air and water are mixed. The

fill intercepts the downward fall of water. The water is mixed with the air contained in the

fill material and water is evaporated and cooled. There are two types of fill: splash fill

and film fill. The falling water hits the splash fill, splashes, and breaks up into smaller

water droplets, resulting in an increased rate of evaporation. The splash fill is made of

wooden slats or bars, plastic, or ceramic tile. Film fill is a compact plastic material,

similar to a honeycomb, that causes water to flow over the fill material, creating a large

wet surface that maximizes evaporation as air travels past the film surface (see Figure

4-11).

Figure 4-11. High-Efficiency Cooling Tower Film Fill

4-1.4.4

Drift Eliminators. The drift eliminators efficiently remove water droplets

from the air and return the recovered water to the cooling tower, thereby minimizing the

loss of cooling tower water. They are located in areas that are situated after the fill and

water sprays and just before the area where the air exits the cooling tower (see Figures

4-6 and 4-8). Drift eliminators are also known as "mist eliminators."

4-1.4.5

Water Distribution and Fan Deck. In a cross-flow cooling tower, the hot

water basin is used to distribute the warm return water flow uniformly over the tower fill

(see Figure 4-6). In a counter-flow cooling tower, water sprays are used to distribute

the warm water (see Figure 4-8). The fan deck supports the motor and fan of the water

spray system. The stack is the structure (typically a cylinder) that encloses the fan and

directs warm, humid discharge air upward and out of the cooling tower.

4-1.4.6

Cell. This is the smallest subdivision of a large cooling tower in which the

fan can operate as an independent unit. A midwall casing must separate each end of

the cell from the adjacent cells to ensure all air flow induced by the cell fan is drawn only

through the cell fill and mist eliminator air path. Figure 4-7 illustrates a typical three-cell

cross-flow cooling tower. Figure 4-9 illustrates a typical four-cell counter-flow cooling

tower.

98

Previous Page

Previous Page