UFC 3-240-13FN

25 May 2005

c) The carbon dioxide removal is: 31 - 2.1 = 28.9 ppm

2-2.6

heated to produce relatively pure water vapor that is then condensed to liquid water and

used for boiler feed. Evaporators are of several different types. The simplest is a tank of

water through which steam coils are passed to heat the water to the boiling point. To

increase efficiency, the vapor from the first tank may pass through coils in a second

tank of water to produce additional heating. Another type of evaporator operates under

a partial vacuum, lowering the boiling point of water and enabling evaporation at lower

temperatures. Following its production in the evaporator, water vapor is cooled and

becomes liquid water that is essentially pure water, without any dissolved solids. Using

evaporators may be economical where inexpensive steam is readily available as the

source of heat. Evaporators also have an advantage over deionization units when the

dissolved solids in the raw water are very high, such as on ocean-going vessels.

2-2.7

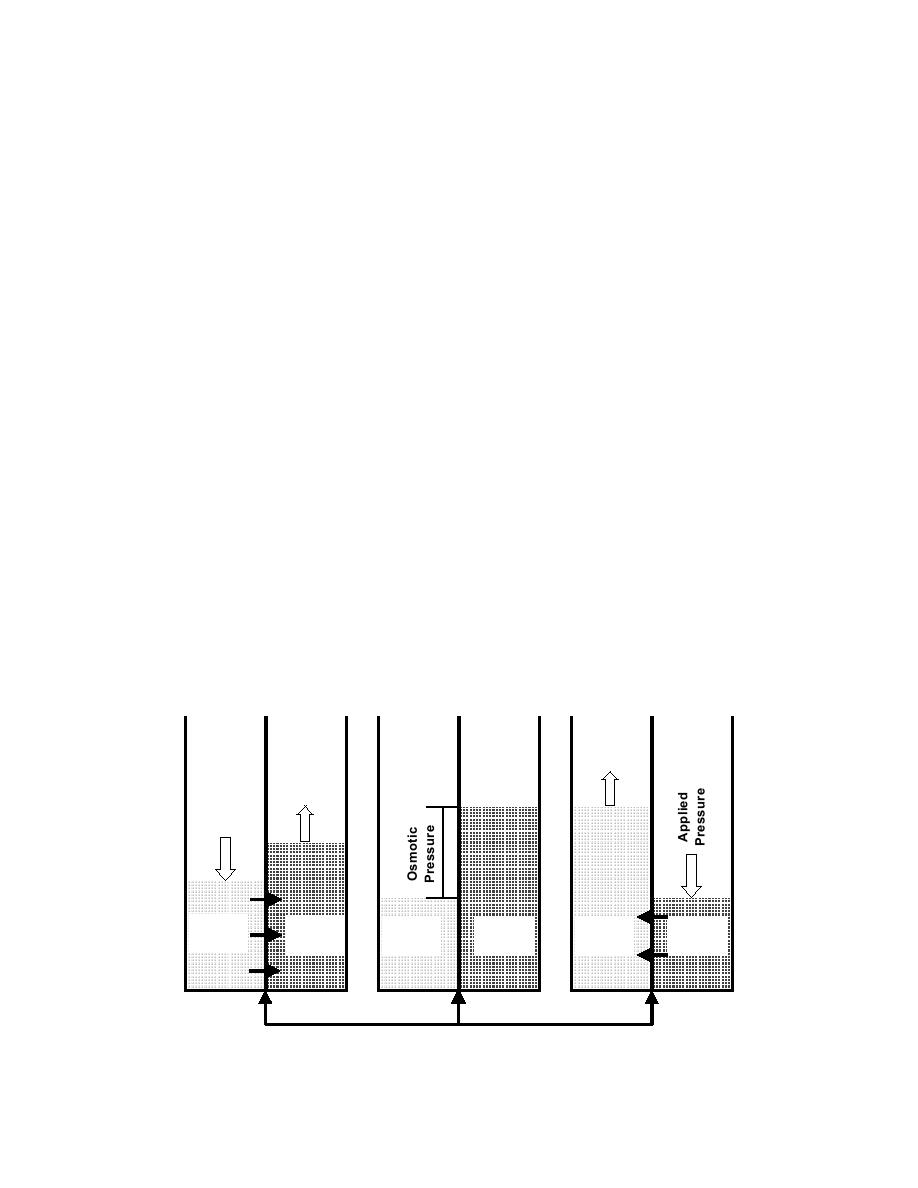

Reverse Osmosis (RO). This process is the opposite of osmosis. It

produces very pure water by separating dissolved minerals from the water. Water

pressure is used to push water though a membrane. The membrane allows only pure

water to pass through. Water thus produced is known as RO product water. All

dissolved solids, organics, and gases that do not pass through the membrane are

removed in the waste stream of RO reject water. Sufficient care must be taken to

protect the membrane from deposits, which reduce efficiency or plug the membrane.

This RO process is illustrated in Figure 2-7. An RO unit is shown in Figure 2-8.

Figure 2-7. RO Schematic

Osmotic

Osmosis

RO

Fresh

Salt

Fresh

Fresh

Salt

Salt

Water

Water

Water

Water

Water

Water

Membranes

29

Previous Page

Previous Page