TM 5-814-3/AFM 88-11, Volume III

(b) Countercurrent centrifuge. The centrifuge illustrated in figure 16-5 operates in the counter-

current mode. Influent sludge is added through the feed pipe; under centrifugal force, sludge solids settle

through the liquid to the bowl wall because their density is greater than that of the liquid. The solids are then

moved gradually by the rotating conveyor from left to right across the bowl, up the dewatering beach to

outlet ports and from there drop downward into a sludge cake discharge hopper. As the settled sludge solids

move from left to right through the bowl toward the sludge cake outlet, progressively finer solids are settled

centrifugally to the rotating bowl wall. The water or centrate drains from the solids on the dewatering beach

and back into the pool. Centrate is actually moved from the end of the feed pipe to the left, and is discharged

from the bowl through ports on the left end, which is the opposite end of the centrifuge from the dewatering

beach. The loca-tion of the centrate removal ports is adjustable and their location establishes the depth of the

pool in the bowl.

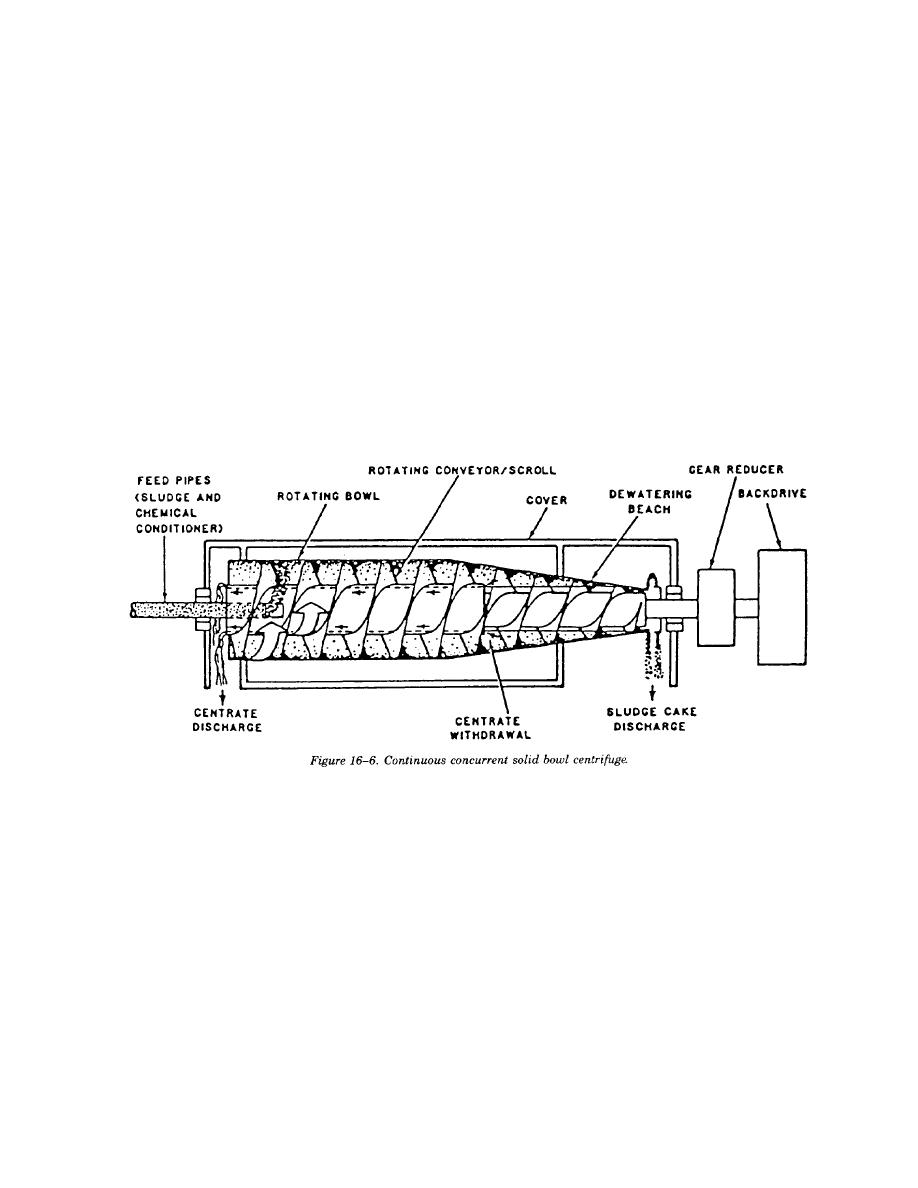

(c) Concurrent centrifuge. A second variation of the solid bowl centrifuge is the concurrent model

shown in figure 16-6. In this unit, liquid sludge is introduced at the far end of the bowl from the dewatering

beach, and sludge solids and liquid flow in the same direction. General construction is similar to the counter-

current design except that the centrate does not flow in a different direction than the sludge solids. Instead,

the centrate is withdrawn by a skimming device or return tube located near the junction of the bowl and the

beach. Clarified centrate then flows into channels inside the scroll hub and returns to the feed end of the

machine where it is discharged over adjustable weir plates through discharge ports built into the bowl head.

(d) Differential speed control. A relatively new development in solid-bowl decanter centrifuges is the

use of a backdrive to control the speed differential between the scroll and the bowl. The objective of the

backdrive is to control the differential to give the optimum solids residence time in the centrifuge and thereby

produce the optimum cake solids content. a backdrive of some type is considered essential when dewatering

secondary sludges because of the fine particles present. The backdrive function can be accomplished with a

hydraulic pump system, an eddy current brake, direct current variable speed motor or a Reeves-type variable

speed motor. The two most common backdrive systems are the hydraulic backdrive and the eddy current

brake.

(e) Installation. Most centrifuge installations have the centrifuge mounted a few feet above the floor

and use a belt conveyor to move dewatered cake away. Other methods of installing a solid bowl centrifuge

are to put the centrifuge on the second floor of a two-story building and drop the dewatered cake into either

trucks or a storage hopper on the first level; to mount the centrifuge about a foot off the floor and to drop

cake onto a screw conveyor built into the floor; or to let the centrifuge cake drop into an open-throated,

progressive cavity-type pump for transfer of the cake to a truck, incinerator or storage.

16-16

Previous Page

Previous Page