TM 5-814-3/AFM 88-11, Volume III

(5) Carbon quantities and adsorption capacity. Carbon requirements range from 250 pounds to 350

pounds of carbon per million gallons treated; 300 pounds per million gallons is the preferred value. The

adsorption capacity of carbon is affected by several factors and should be determined experimentally for each

particular wastewater to be treated. Factors which influence adsorption include surface area, nature of the

material to be adsorbed (adsorbate), pH, temperature, nature of carbon (adsorbent), and complexity of

material to be adsorbed. The adsorption capacity of carbon per cycle usually ranges from 0.25 to 0.87 pounds

COD removed per pound of carbon applied. Th obtain guidance regarding the selection of the type of

activated carbon to be used in bench-scale or pilot-scale studies, refer to chapter 4 of the EPA Process Design

Manual for Carbon Adsorption.

c. Equipment. The effluent quality requirement will deterimine the required contact time and this in turn

will set the approximate total carbon volume. The hydraulic loading will determin the total cross-sectional

area and total carbon bed depth. The total bed depth can be divided between beds in series, and the total

cross-sectional area can be divided into separate carbon beds in parallel. Vessel heights should provide for

bed expansion of 50 percent. Contact tanks should have length-to-diameter ratio of between 0.75 and 2.0,

with carbon depth usually greater than 10 feet. The tanks should be constructed of concrete or lined carbon

steel. Typical coating materials range from a painted, coal tar epoxy to laminated rubber linings. The carbon

transport system must be designed to resist the abrasiveness of carbon slurry. More specific design details

can be obtained from the EPA Process Design Manual for Carbon Adsorption and from equipment

manufacturers.

15-7. Phosphorus removal.

1. General approaches. Mineral addition and lime addition are the principal methods for in-plant removal

of phosphorus from wastewater. The most commonly used of these metal salts are: alum, a hydrated

aluminum sulfate (Al2SO4)3.18 H20); sodium aluminate (Na2O.Al2O3); ferric sulfate (Fe2(SO4)3); ferrous

sulfate (FeSO4); ferric chloride (FeCl3); and ferrous chloride (FeCl2). Mineral addition is usually followed by

anionic polymer addition, which aids flocculation; the pH may require adjustment depending on the particular

process. In lime addition, phosphorus removal is attained through the chemical precipitation of

hydroxyapatite, Ca5OH (PO4)3. When designing the phosphorus removal system, consideration must be given

to the phosphorus levels in the system effluent suspended solids. Additional information may be found in the

EPA Process Design Manual for Phosphorous Removal.

b. Mineral addition using aluminum.

(1) Aluminum requirements. The theoretical requirement for aluminum (Al) in the precipitation pro-

cess is a mole ratio of aluminum to phosphorus of 1:1. Actual case histories have indicated considerably

higher (2:1) than stoichiometeric quantities of aluminum are needed to meet phosphorus removal objectives.

Alum, Al2(SO4)3.18H2O, is the aluminum additive most frequently used, with sodium aluminate being

substituted when alum addition would force the pH too low for other treatment processes. The theoretical

weight ratio of alum to aluminum is 11:1 and in practice alum weight ratios in the range of 13:1 to 22:1

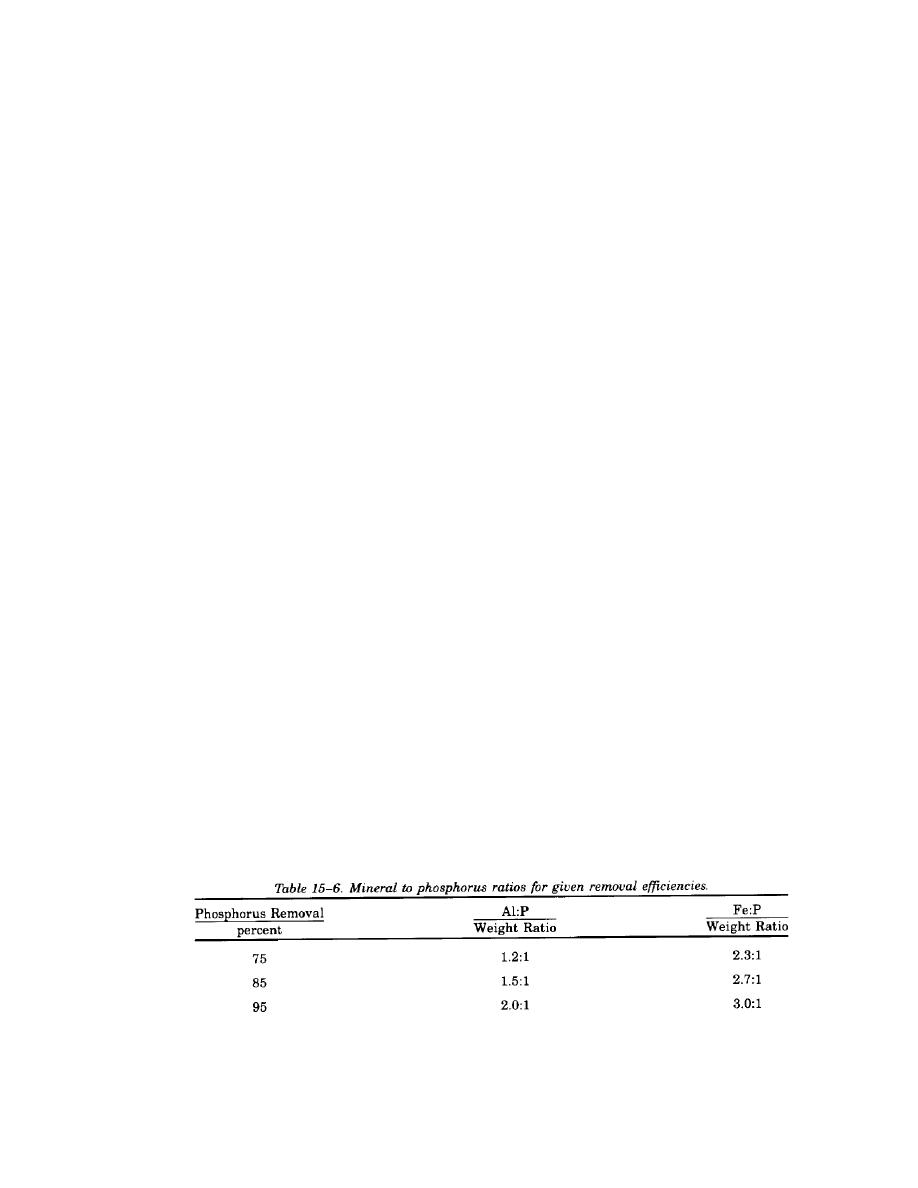

(depending on the degree of removal desired) have been needed. For higher removal efficiencies, the Al:P

ratio must be increased. Table 15-6 lists the Al:P (and Fe:P) ratios required for 75, 85 and 95 percent

phosphorus removal. Laboratory, pilot plant, or full-scale trial runs are often necessary to determine the most

effective mineral dosages.

(2) Addition at primary treatment stage. In the primary treatment stage, the mineral is added

directly to the raw sewage which is then mixed, adjusted for pH (if necessary), flocculated, and clarified. The

mixing and flocculation are to be carried out in specially designed units, or within existing systems at

15-11

Previous Page

Previous Page