TM 5-814-3/AFM 88-11, Volume III

15-5. Filtration.

a. Basic design parameters. The basic parameters to consider are the following:

-- Type and size of filter media;

-- Depth of filter;

-- Rate, duration and timing of backwash;

-- Filter run duration;

-- Filtration rate; and

-- Type of chemical pretreatment dosage requirement.

b. Coarse-media filtration.

(1) General design consideration. Filter media size will influence filter performance; smaller media

will achieve better suspended solids removal, but will involve increased pressure drop and head loss buildup.

Therefore, a balance between removal efficiency and hydraulic loading rate must be attained. For sewage

applications, coarser media, higher flow rates and longer filter runs will be used. Chemical treatment of the

feed water may be necessary to improve effluent quality.

(2) Media sizes and filtration rate. Coarse media particles must have an effective size of

approximately 1.3 millimeters with a uniformity coefficient of approximately 1. Sand or anthracite coal may

be used, with coal giving a poorer solids removal but producing less pressure drop. Refer to the EPA Process

Design Manual for Suspended Solids Removal for additional information regarding media specification.

The design application rate for coarse-media filters will be 5 gallons per minute per square foot at design

maximum flow.

(3) Effectivenness. Single-media, coarse sand filters will be credited with 60 percent removal of

suspended solids when the sand media size is no greater than 1.0 millimeters and the flow rate is no greater

than 4 gallons per minute per square foot. Biochemical oxygen demand removal efficiencies will be dependent

on the biochemical oxygen demand fraction of the suspended solids that is removed since dissolved organic

materials generally pass through the filter.

c. Multi-media filtration. Multi-media filtration, as compared to single-media filtration, will provide

better suspended solids removal with longer filter runs at higher flow rates. A 75 percent suspended solids

removal efficiency with multi-media filtration will be an acceptable design allowance for a design application

rate of 5 gallons per minute per square foot. Filter aids such as alum can be used to increase removal

efficiency. An application rate of 6 gallons per minute per square foot at maximum design flow will be utilized

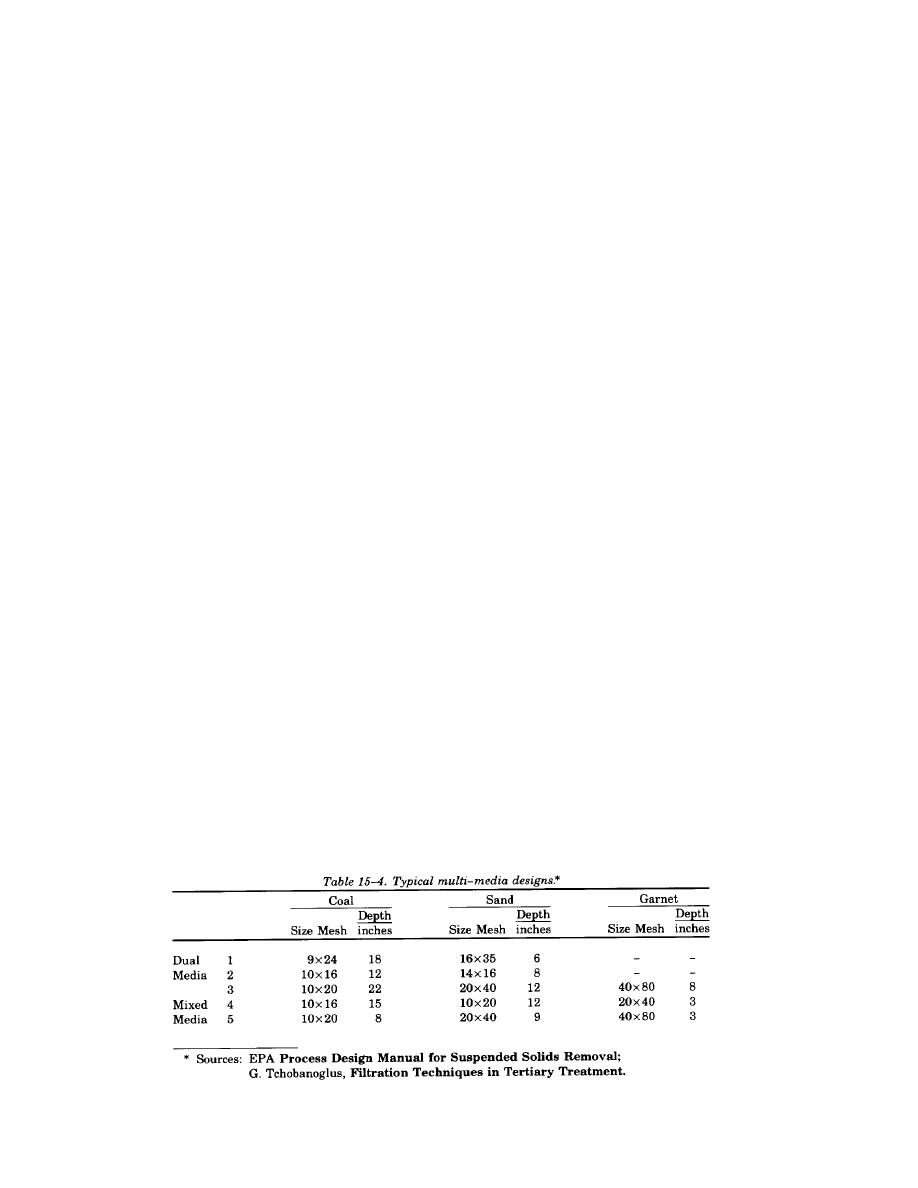

for design. Typical design parameters for multi-media filtration processes are given in tables 15-4 and 15-5.

15-8

Previous Page

Previous Page