TM 5-814-3/AFM 88-11, Volume III

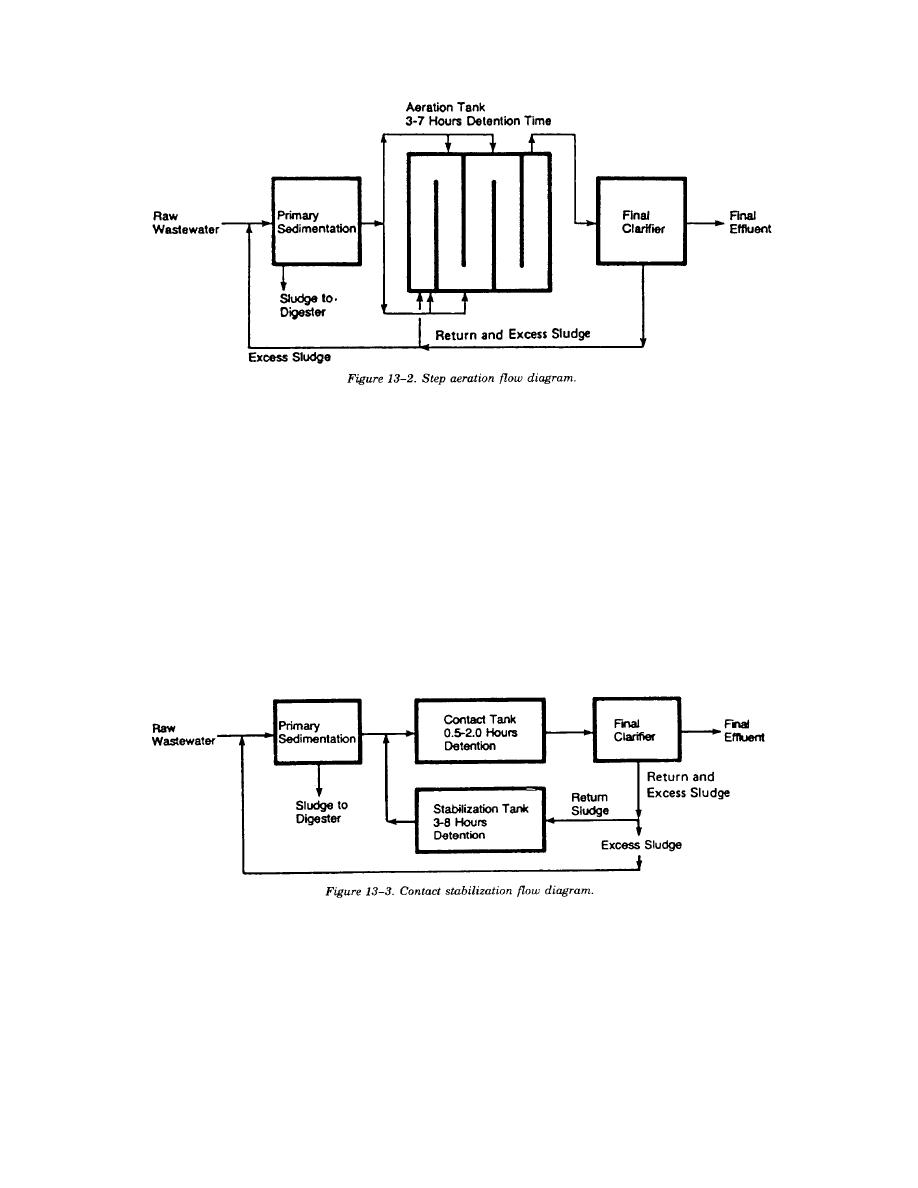

c. Contact stabilization. The contact stabilization activated sludge process (fig 13-3) is characterized

by a two-step aeration system. Aeration of short duration ( to 2 hours) is provided in the contact tank

where raw or primary-settled wastewater is mixed with the activated sludge in the contact tank. The effluent

from the contact tank is then settled in a final settling tank. The settled activated sludge to be recycled from

the final clarifier is drawn to a separate re-aeration in a stabilization basin for 3 to 8 hours of aeration time.

It is then returned to the contact aeration basin for mixing with the incoming raw wastewater or primary-

settled effluent. In addition to a shorter wastewater aeration time, the contact stabilization process has the

advantage of being able to handle greater shock and toxic loadings than conventional systems because of the

buffering capacity of the biomass in the stabilization tank. During these times of abnormal loadings, most of

the activated sludge is isolated from the main stream of the plant flow. Contact stabilization plants will not

be used where daily variations in hydraulic or organic loadings routinely exceed a ratio of 3:1 on consecutive

days or for plants with average flows less than 0.1 million gallons per day without prior approval of HQDA

(CEEC-EB) WASH DC 20314-1000 for Army projects and HQ USAF/LEEE WASH DC 20332 for Air

Force projects.

d. Completely-mixed activated sludge. In the completely-mixed process (fig 13-4), influent wastewater

and the recycled sludge are introduced uniformly through the aeration tank. This allows for uniform oxygen

demand throughout the aeration tank and adds operational stability when treating shock loads. Aeration time

ranges between 3 and 6 hours. Recirculation ratios in a completely-mixed system will range from 50 to 150

percent.

13-2

Previous Page

Previous Page