TM 5-814-3/AFM 88-11, Volume III

CHAPTER 11

PRIMARY TREATMENT

11-1. Function.

The purpose of primary treatment is to remove solids which are not removed during preliminary treatment

(chap 10). Processes which can be used to provide primary treatment include the following: 1) primary

sedimentation, also called clarification; 2) microscreens; and 3) Imhoff tanks. In most facilities, primary

treatment is used as a preliminary step ahead of biological treatment.

11-2. Primary sedimentation.

Sedimentation tanks are designed to operate continuously. They are usually rectangular or circular and have

hoppers for sludge collection. Most sedimentation tanks are constructed with gently sloped bottoms and have

sludge hoppers with relatively steep sides. Non--mechanized settling tanks are used only in very small

installations; the sludge moves to hoppers by gravity, where it is removed.

a. Function. Primary sedimentation tanks may provide the principal degree of wastewater treatment, or

may be used as a preliminary step in further treatment of the wastewater. When used as the only means of

treatment (no longer authorized in U.S. and Trust territories), these tanks provide for removal of settleable

solids and much of the floating material. When used as a preliminary step to biological treatment, their

function is to reduce the load on the biological treatment units. Efficiently designed and operated primary

sedimentation tanks should remove 50 to 65 percent of the suspended solids and 25 to 40 percent of the

biochemical oxygen demand.

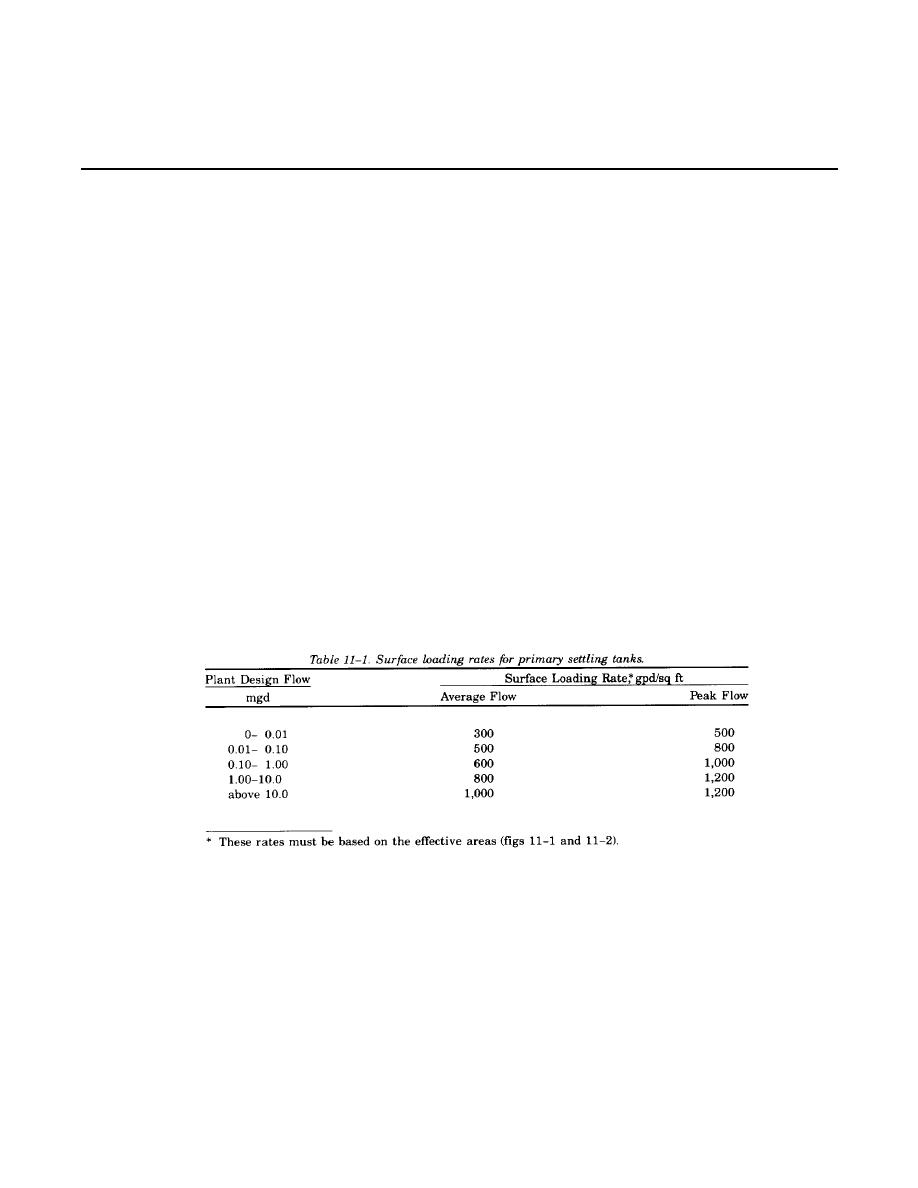

b. Design parameters. The tanks will be designed for the average daily flow or daily flow equivalent to

the peak hourly flow that requires the largest surface area. Table 11--1 shall be used to select the correct

surface loading rate. All tank piping, channels, inlets, outlets and weirs will be designed to accommodate peak

flows. Use 3.0 times the average hourly flow if specific peak flows are not documented.

Each tank will be sized, as a maximum, for 67 percent of the plant design flow (facility designs will normally

include two tanks). At treatment plants with less than 0.1 million gallons per day treatment capacity, one unit

is acceptable when an equalization tank or holding basin is constructed with adequate volume to dampen out

peak inflow rates.

11-1

Previous Page

Previous Page