TM 5-814-3/AFM 88-11, Volume III

10-5.

Dissolved air flotation.

Flotation is a unit process whereby particulate matter is separated from a wastewater, causing the matter to

float to the liquid surface. Criteria are provided in the EPA Manual 625/1-74-006. Dissolved air flotation

units will not be installed without permission from HQDA (DAEN-ECE-G) WASH DC 20314-1000 for

Army projects or HQ USAF/LEEE WASH DC 20332 for Air Force projects. Permission will be granted only

when adequate laboratory or pilot studies data are available and when adequate justification for the additional

maintenance and operational labor requirements is provided.

10-6.

Wastewater flocculation.

Flocculation units will be used and will immediately precede clarification units when a chemical precipitation

process is employed as part of primary, secondary, or advanced wastewater treatment schemes.

a. Methods. Porous diffuser tubes or plates are commonly used for air agitation; but perforated pipes,

impingement diffusers, jet diffusers, or helix-type diffusers may also be used for air flocculation. Mechanical

flocculation is achieved by revolving or reciprocating paddles, radial-flow turbine impellers, or draft tubes.

In typical situations, mechanical aerators (vertical draft tube type) will be used in single tanks arranged for

cross flow.

b. Design factors. Mechanical and air flocculation units for domestic wastewater will be designed for 30

minutes of flocculation detention time followed by a clarifier with surface settling rates of 800 gallons per

day per square foot. The air requirement for flocculation is 0.1 standard cubic feet per gallon at 30 minutes

of detention time. To insure proper agitation, air will be supplied at 2.5 standard cubic feet per minute per

linear foot of tank channel. The number and size of air diffusers are determined by dividing the total air

requirement by the optimum air diffusion rate per unit (4.0 cubic feet per minute per square foot of porous

diffuser area). Water depths vary from 8 to 13 feet. In rectangular tanks, the ratio of length to width will be

3:1 For mechanical flocculation, revolving paddles may be either horizontal or vertical. Peripheral-paddle

speed should be kept in the range of 1.0 to 3.0 feet per second to minimize deposition and yet avoid

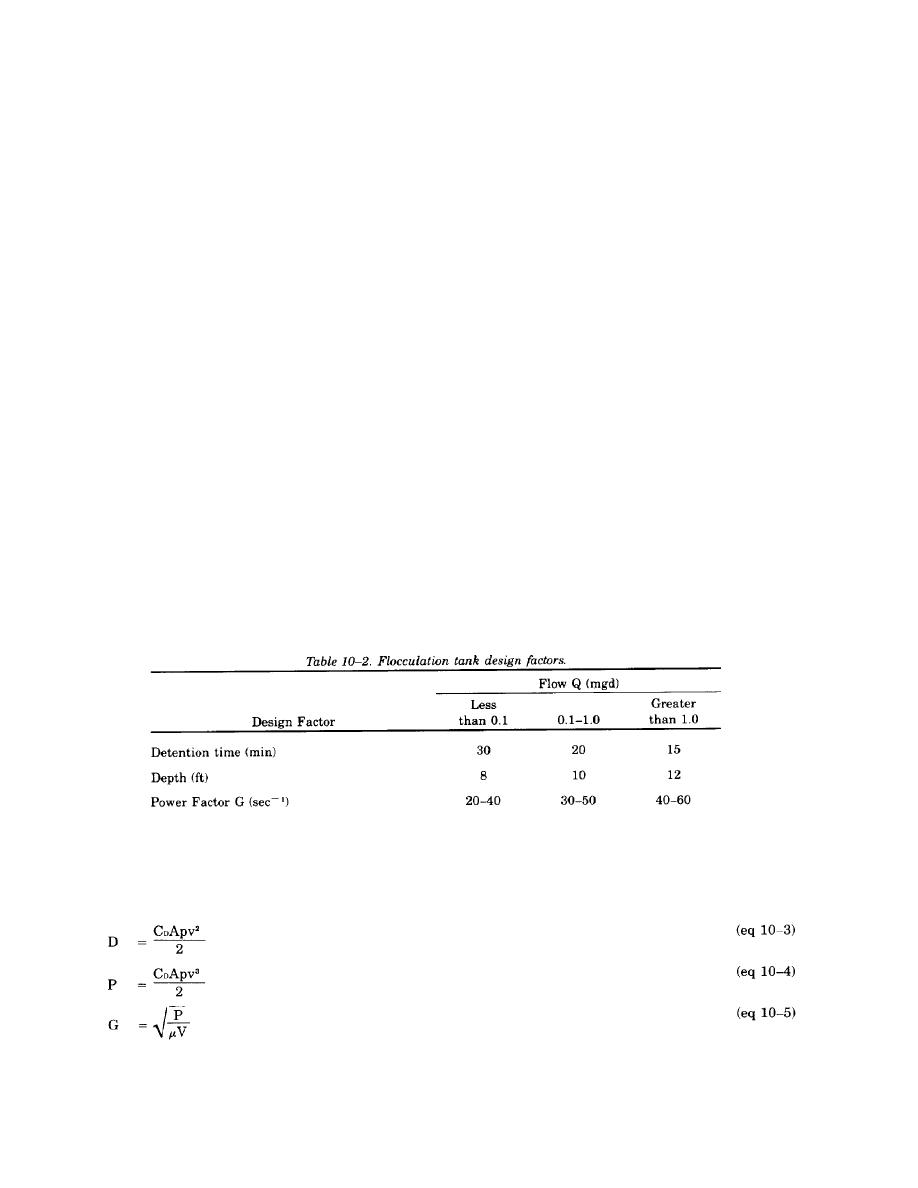

destruction of the flocs. Table 10-2 presents values for design factors to be used in designing typical sewage

treatment plants.

c. Power Requirements. To compute the power requirements and velocity gradient requirements,

the following formula should be used:

10-10

Previous Page

Previous Page