TM 5-813-3/AFM 88-10, Vol 3

CHAPTER 5

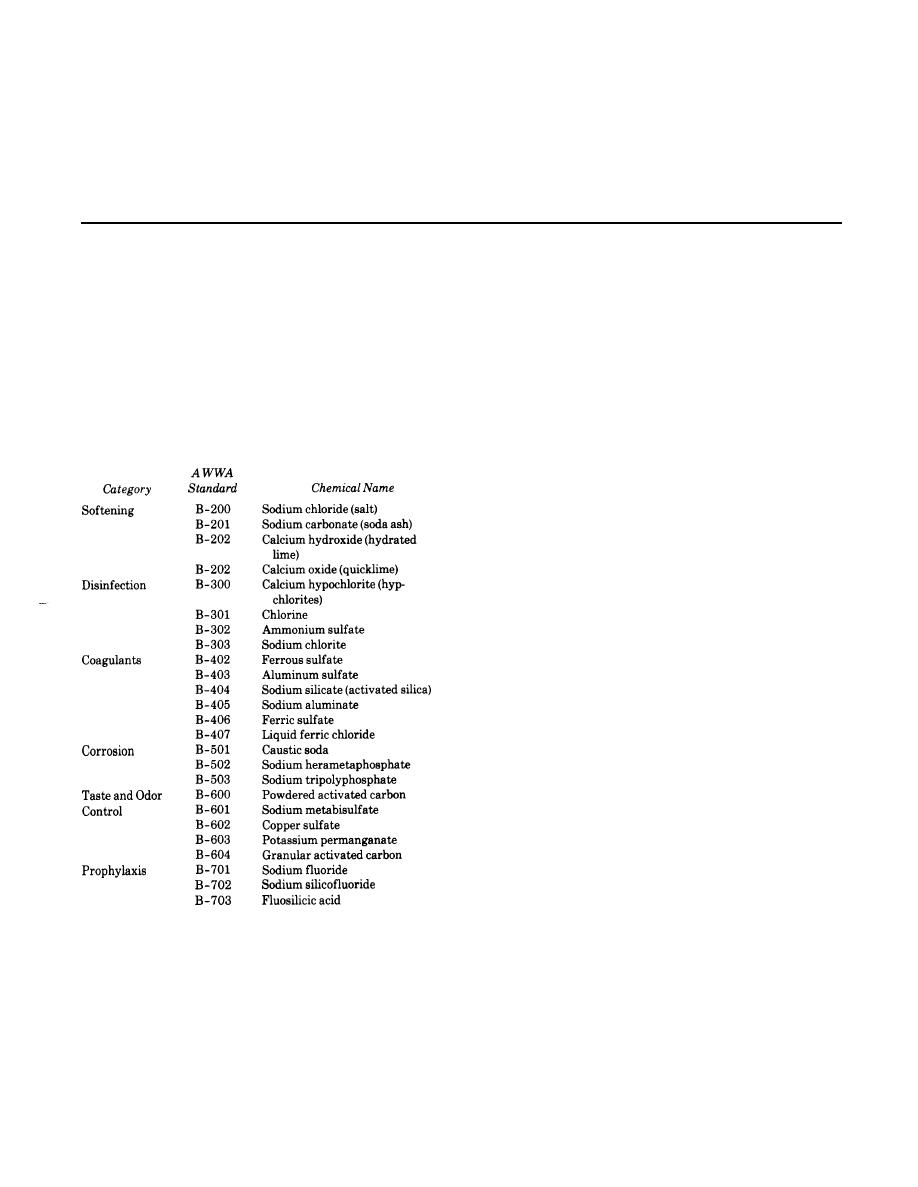

WATER TREATMENT CHEMICALS

istics of the chemical. Bulk liquids are usually unload-

5-1. Chemical properties.

ed by pumping from the tank truck or railroad car to

Chemicals are used for a variety of purposes in conven-

the storage tanks at the treatment plant. Bulk pow-

tional water treatment practice, including coagulation

ders can be unloaded by pneumatic unloading and con-

and flocculation, disinfection, fluoridation, taste and

veyance devices, or if the powder is to be mixed or dis-

odor control, and pH adjustment. The most common

solved in water, it can be unloaded directly into a wa-

chemicals and some of their characteristics are listed

ter eductor in which the powdered chemical and the

in table 5-1.

water are mixed as the water is flowing to the storage

5-2. Chemical

tank, Chemical crystals or granules are usually unload-

standards.

ed by mechanical devices, such as bucket elevators and

Chemicals used at military water treatment plants will

conveyor belts. All three forms of bulk chemicals can

meet the applicable standards of the AWWA. The

be unloaded by gravity if the chemical storage tanks or

AWWA publication number for these standards are:

bins are located below ground near the railroad tracks

or roadway. Chemicals shipped in bags, drums, bar-

rels, or other shipping containers can usually be stored

by placing these containers in a specified storage area,

Hazardous chemicals must be stored in separate rooms

to avoid reaction of chemical vapors. The supply of

chemicals in storage at a water treatment plant should

always be at least equal to the projected 30-day re-

quirements. Under some circumstances, it may be de-

sirable to maintain larger supplies of essential chemi-

cals, such as chlorine or coagulant, and smaller sup-

plies of nonessential chemicals, such as fluoridation

agents.

5-4. Chemical

application.

a. Dry chemicals. Dry chemicals are usually convert-

ed to a solution or slurry prior to application to the wa-

ter. Measurement of the chemical application rate is

accomplished by the dry-feed machine. The measured

quantity of chemical is then dissolved or slurried in a

small amount of water for transport to the feed point,

where the solution or slurry must be rapidly and thor-

oughly mixed with water being treated. Before quick-

lime can be applied to water, it must be hydrated in a

slaker. Either retention-type or paste-type slakers may

be used at military water treatment plants. If a reten-

5-3.

Chemical

handling

and

storage.

tion-type slaker is used, a temperature of 160 F or

In the design of water treatment facilities, the selec-

greater will be maintained in the slaker. All slakers

tion of methods of chemical handling and storage must

must be equipped with grit removal mechanisms.

be based primarily on ease of operation, operating flex-

b. Liquid chemicals. Chemical solutions or slurries

ibility, and safety considerations. If chemicals are to

are applied directly, or after dilution, to the water be-

be received in shipping containers such as bags, boxes,

ing treated by volumetric liquid feeders such as meter-

drums, or canisters, equipment required for chemical

ing pumps or rotating wheel feeders. Rapid, thorough

handling may include carts, dollies, fork lifts, cranes,

mixing of the chemical solution or slurry with the wa-

etc. If chemicals are shipped in bulk quantities, the

mode of unloading depends on the physical character-

ter is essential,

5-1

Previous Page

Previous Page