TM 5-803-11/AFJMAN 32-10139

11-3. Safety Surfaces.

face meets the ASTM F 1292 standard. For instance,

a particular surfacing material may not meet test

Adequate safety surfacing throughout play equip-

criteria for a fall from 2400 mm (96 inches), but will

ment use zones is an essential safety requirement.

meet criteria for a 1800 mm (72-inch) fall. It can

Falls from play equipment represent over 70% of all

then be said that this surfacing material has a 1800

playground equipment-related injuries treated in

mm (72-inch) critical height. The critical height of

hospital emergency rooms. Without appropriate

safety surfacing material used in children's play ar-

safety surfacing, these falls may result in perma-

eas will equal or exceed the highest accessible height

nent head injury or death.

of the equipment provided. The highest accessible

a. Types of Safety Surfacing. A number of safety

height of various types of play equipment is mea-

surfacing materials are available. Each type of

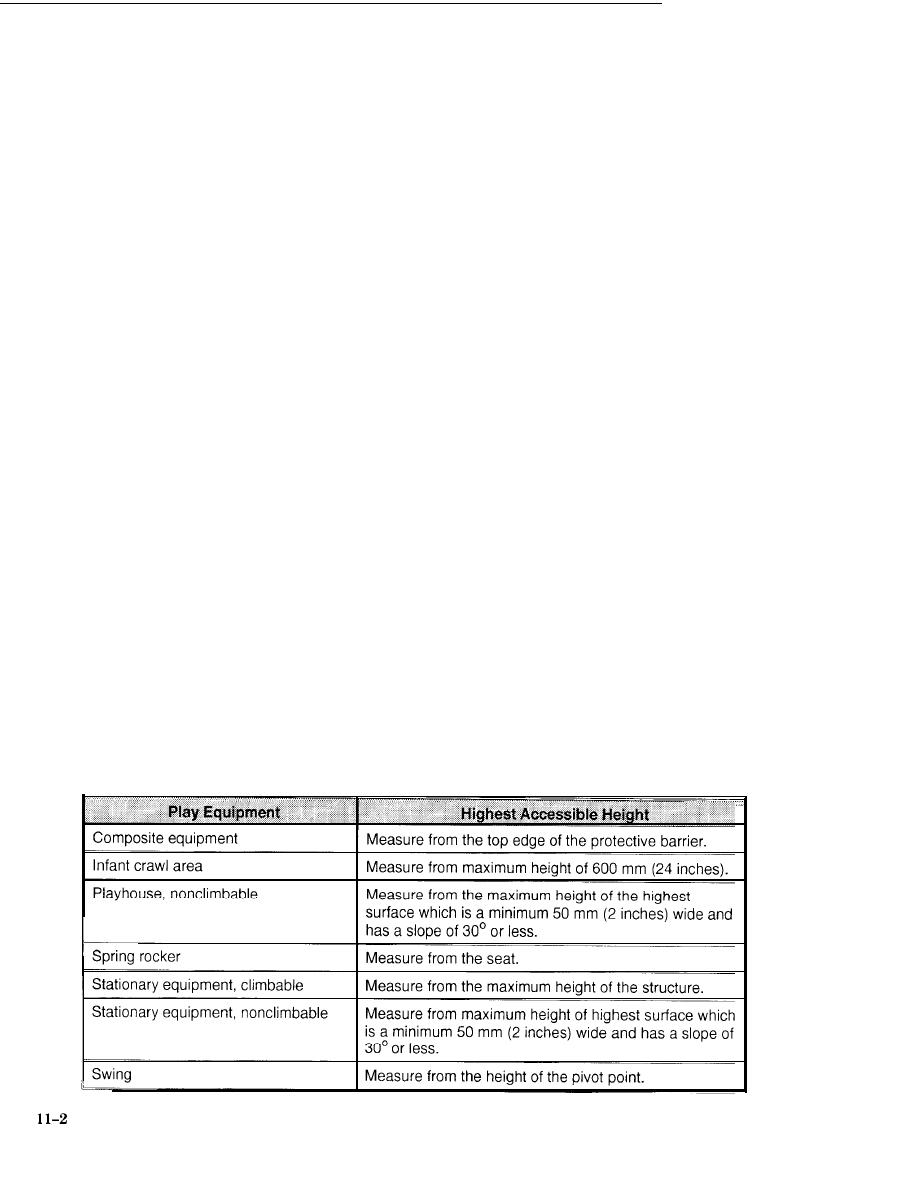

sured from different points. Table 111 describes

safety surfacing has unique advantages and disad-

how the highest accessible height is determined for

vantages. The two major types of safety surfaces are

manufactured play equipment.

synthetic surfacing and loose-fill surfacing. Syn-

d. Manufactured Safety Surfacing. Testing data

thetic surfacing includes tiles that are formed in the

should be obtained from manufacturers of synthetic

factory, or surfacing that is poured in place onsite.

surfaces, chopped tire surfaces, or wood products

Loose-fill surfacing includes organic and inorganic

manufactured as safety surfacing to verify that the

materials, such as sand, gravel, chopped tire, and

surface meets the requirements of ASTM F 1292 for

wood products.

a headfirst fall from the highest accessible equip-

b. Impact Attenuation Criteria. Standards for im-

ment height to be provided.

pact attenuation have been developed with the goal

of reducing severe head injury or death from falls

e. Loose-Fill Surfacing. Loose-fill materials are

from manufactured play equipment. Safety surfaces

often not manufactured specifically as safety surfac-

that meet the requirements of ASTM F 1292 will be

ing. Therefore, test data is often not available from

provided throughout the play equipment use zone.

suppliers. In 1993, the U.S. Army Corps of Engi-

ASTM F 1292 states that the surface must yield

neers commissioned a testing program to develop

both a peak deceleration of no more than 200 g's

recommended material depths for loose-fill sur-

and a Head Injury Criteria (HIC) value of no more

faces. Materials tested include sand, pea gravel,

than 1,000 for a headfirst fall from the highest ac-

and bark mulch. To reproduce required impact-

cessible height of the play equipment. G-force mea-

attenuating performance, the materials must meet

sures the peak deceleration of the head during im-

the requirements in this chapter; the maximum ac-

pact. HIC measures the duration of the impact

cessible height of play equipment must not exceed

during its most sever phase.

2400 mm (96 inches); and the surface must receive

c. Critical Height of Safety Surfacing Materials.

regular maintenance to maintain material depth. A

The performance of safety surfacing is measured

25 mm (l-inch) difference in material depth may

from potential fall heights. The critical height of a

dramatically increase injury potential. Table 112

surfacing material is the maximum height at which

describes the recommended installed material

a headfirst fall from equipment onto the safety sur-

depth for loose-fill surfacing.

Table 11-1. Highest Accessible Equipment Height,

Previous Page

Previous Page