TM 5-805-6

d. Caulking. Oil- and resin-based caulking is

inexpensive and oxidizes to form a tack-free sur-

face skin that can be painted.

(1) Oil- and resin-based caulking must be used

with caution because it shrinks while curing,

hardens with aging, cannot be immersed in water,

and has limited resistance to joint movement.

Applications should be limited to rigid interior

joints not more than 6.3 mm ( inch) wide because

the caulking lacks elasticity and may shrink as

much as 20 percent. Paint will extend the service

life of caulking and will protect the material from

occasional exposure to water.

(2) Oil- and resin-based caulking should be

applied at temperatures between 4 and 38 degrees

C (40 and 100 degrees F). The service temperature

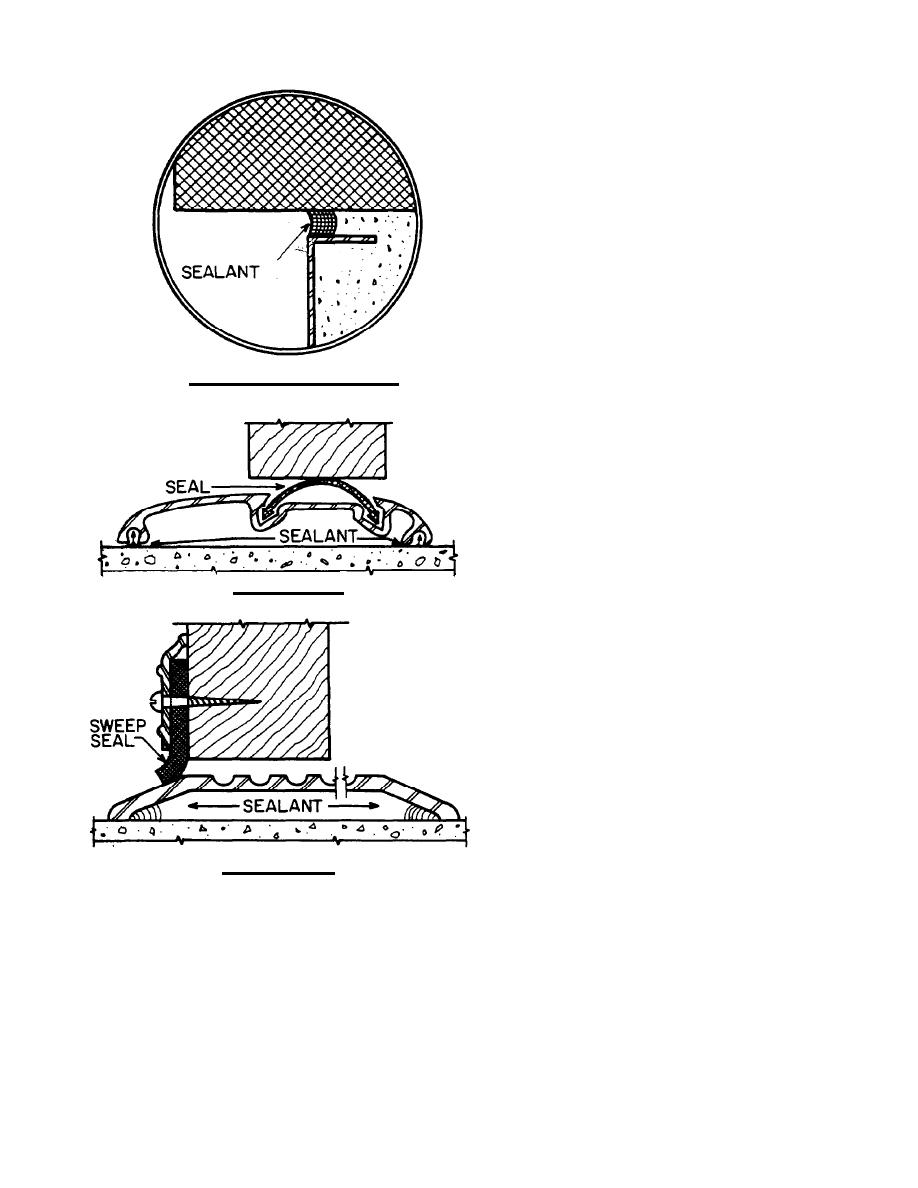

HEAD AND JAMB DETAIL

range is from -30 to 39 degrees C (- 20 to + 150

degrees F). Type I is used in caulking guns and

Type II is applied with a putty knife.

e. Latex sealants. Latex sealants adhere well to

wood, masonry, and concrete. Depending on the

grade of material, these sealants have varied

weather resistance which is improved by applying

a coat of paint.

(1) Latex sealants may shrink as much as 30

percent while curing and have limited resilience

when cured. Consequently, latex sealants should

be used only for temporary or low budget construc-

SILL DETAIL

tion where joint movement does not exceed 15

percent of the joint width.

(2) Many acoustic applications can be satisfied

with latex sealants, as shown in ASTM C 919.

(3) The binder in a latex sealant may be

natural rubber or a synthetic polymer. The most

common latex sealants are based on a water-

dispersed acrylic polymer, thus the terms "latex"

and "acrylic" are often used interchangeably.

f. Acrylic sealants. Acrylic sealants are widely

used because they are inexpensive and adhere well

to most porous surfaces. Most acrylic sealants are

water dispersed ("latex") but they are also avail-

able in solvent dispersions. These sealants usually

shrink up to 30 percent during the curing process.

SILL DETAIL

The service temperature range for acrylic sealants

is from -30 to +84 degrees C (-20 to +180

degrees F). A quality acrylic sealant may have a

Figure 7. Exterior Door and Threshold.

life expectancy up to 20 years.

(1) The quality of acrylic sealants varies; the

c. Primer. Some sealants require a primer to

higher the acrylic polymer content, the better the

promote adhesion to all substrates. More often, a

flexibility and resistance to weathering (and the

primer is only needed on a non-porous substrate

higher the cost). Solvent based systems often have

such as glass or metal. A primer is generally

better water resistance than those dispersed in

desinged for use with a particular commercial

water.

(2) Acrylic sealants should not be exposed to

sealant and may be restricted to specified sub-

strates. Primers should be provided (and used as

standing water and they do not bond well to bare

metal or glass unless a primer is applied first.

recommended) by the sealant manufacturer.

6

Previous Page

Previous Page