TM 5-805-6

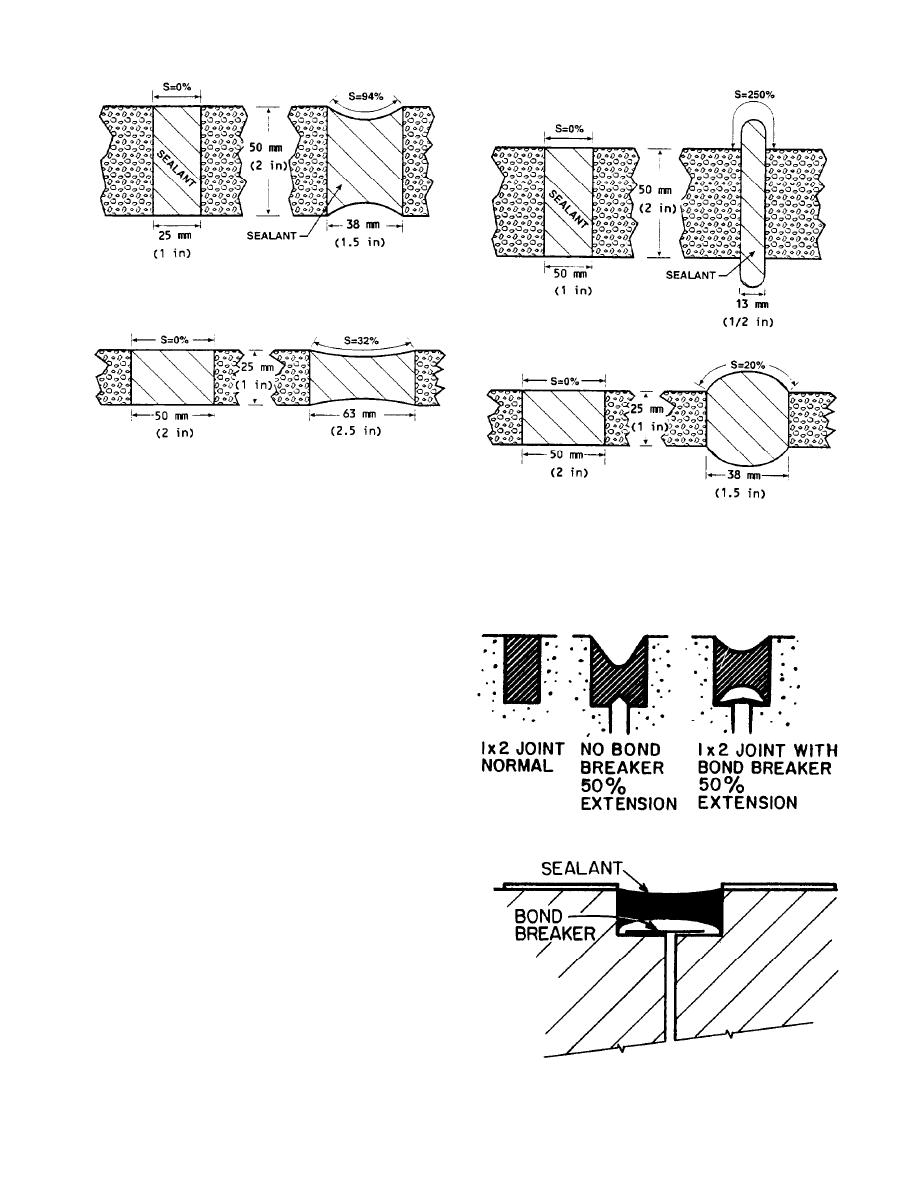

S = SURFACE ELONGATION

Figure 1. Joint Extension.

S = SURFACE ELONGATION

percent in the narrow joint, but only 20 percent in

Figure 2. Joint Compression.

the wide joint.

(4) Effect of bond-breaker and backing. Figure

3 shows how the top surface elongation is greatly

increased when the sealant is bonded to the

bottom of the joint and the joint is elongated or

compressed. Figure 4 shows the location of a bond

breaker which prevents the sealant from adhering

to the bottom of the joint. Where the joint is

deeper than the sealant, a backing material is

used to support the sealant as shown in figure 5.

The backing may prevent adhesion, thus acting as

a bond breaker, or it may be sufficiently flexible to

move with the sealant.

Figure 3. Effect of Bond-Breaker.

e. Temperature. The maximum temperature

range that a joint must withstand depends on the

service temperature of the adjacent materials.

Service temperatures amy exceed ambient, as dis-

cussed below. Coefficients of thermal linear expan-

sion are quite different for various materials, as

listed in ASTM C 1193. Thermal expansion also

varies at different parts of the temperature range

and is affected by variations in thickness or

composition. As a result, when calculations require

an exact coefficient of thermal expansion of a

material, it is best obtained from the manufact-

urer of that specific material and for the exact

thickness and expected temperature range to be

Figure 4. Bond-Breaker in Shallow Joint.

2

Previous Page

Previous Page