TM 5-852-5/AFR 88-19, Volume 5

(a) Special requirement. A permanent ice

(3) Activated sludge systems. Systems that have

cover must be avoided in the aeration compartments

been successfully used in cold regions include

of activated sludge systems. An ice cover will inhibit

conventional and pure-oxygen activated sludge,

atmospheric aeration and will entrap solids, both of

contact stabilization, and extended aeration con-

which reduce treatment efficiency. The design must

cepts, both in package plants and in oxidation

provide for a minimum of exposed liquid surface

ditches. Basic design criteria for these processes can

area to reduce heat losses. An unheated shelter, a

be found in TM 5-814-3/AFM 88-11, Vol.3. When

temporary tank cover or a wind break is required

the system is enclosed and incoming waste-water

during the winter. Clarifiers associated with these

temperatures exceed 50 degrees F, basic design

systems will require similar protection to avoid

criteria will apply. Special measures are necessary

freezing and to inhibit density currents. A

only when incoming wastewaters are below 50

continuously heated building is not necessary to

degrees F or if a significant temperature drop is

maintain treatment efficiency. Operator comfort and

expected within the system. All of the biological

convenience are the only justifications for such

reaction rates involved are temperature sensitive,

energy inputs. If the incoming sewage is 50 degrees

and must be adjusted using:

F or warmer there is sufficient heat in the liquid to

sustain a protected treatment process. A standby

heat source and emergency power are recommended

for extended power failures and other emergencies.

where

(b) Extended aeration. Extended aeration

units have been successfully operated with liquid

kT = reaction rate coefficient at temperature T

temperatures as low as 33 degrees F and have still

k20 = reaction rate at 20 degrees C

produced high quality effluent. Design organic

T = design wastewater temperature, degrees C

loadings (food/microorganism ratio) of up to 0.08 lb

2 = temperature coeeficient.

BOD (biochemical oxygen demand)/lb MLSS/day,

and mixed liquor suspended solids (MLSS) concen-

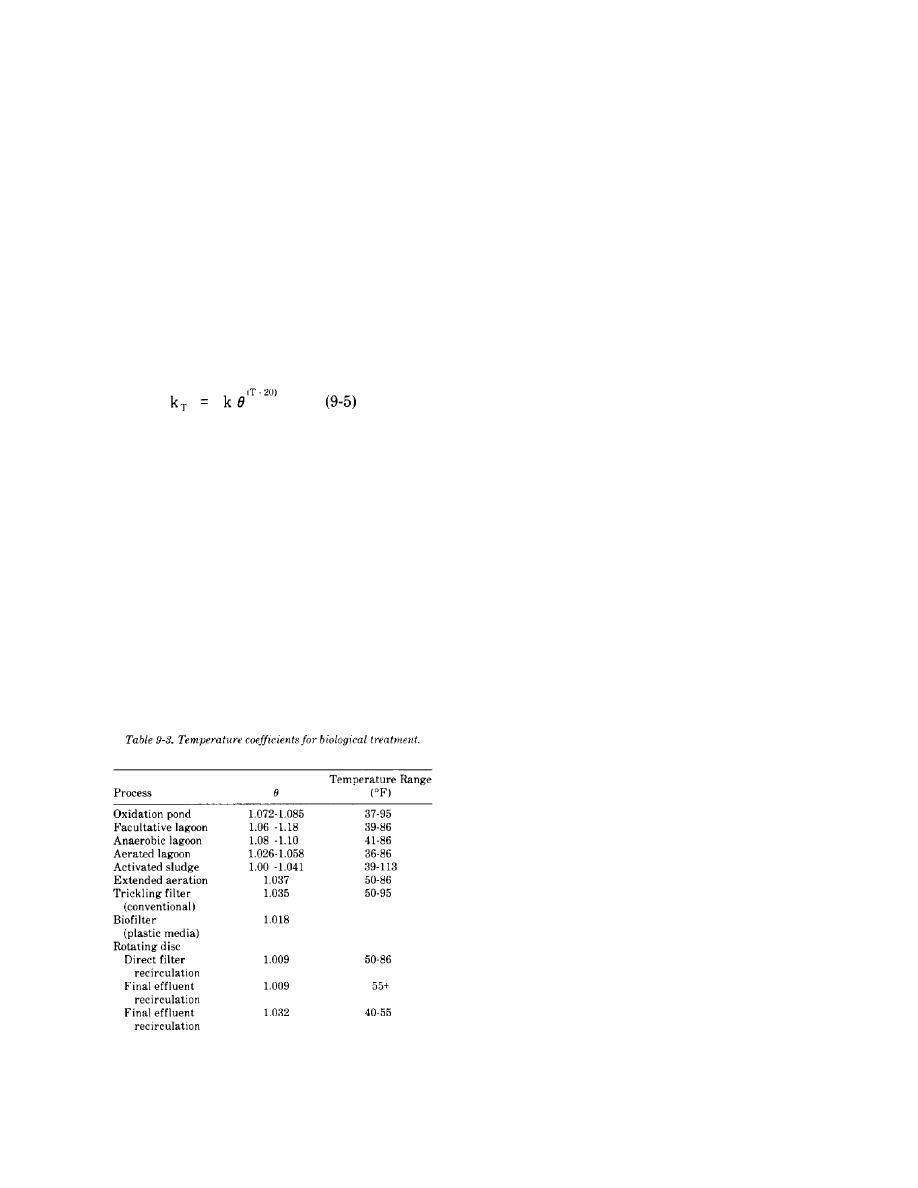

The 2 values given in table 9-3 will be used in

trations of 3000-40000 mg/L are recommended for

equation 9-5 to adjust the reaction rate for the

low temperature operation. Small packaged treat-

design wastewater temperature. The basic reaction

ment units must be covered and must be protected

rate coefficients are found in TM 5-814-3/AFM 88-

from the wind. Pumps, motors, blowers, external

11, Vol.3.

pipes, valves and similar appurtenances will require

heat as well as a protective shelter. These systems

must not be oversized or overdesigned with respect

to hydraulic capacity, because low organic loadings

usually result in poor performance. Dual units are

required for low, intermittent flows at remote

installations. Only one unit is operated during low

flow periods. This unit is operated with a MLSS

concentration. Sludge is then transferred to the

second unit during peak flow periods allowing an

immediate start-up. Figure 9-5 illustrates the special

features of an oxidation ditch in the Subarctic. The

aeration basin has vertical sidewalls and a vertical

central divider. This reduces exposed surface area

and heat losses by about 32% as compared to the

conventional ditch with sloping sidewalls and center

island. The only heated space in this treatment

system is the office/laboratory clarifier equipment

and aeration brushes are housed in simple concrete

block construction. Condensation and ice forms on

the interior surfaces of exterior walls. Thus

switches, control panels, etc., must be located on

dry interior walls. These features are not unique to

oxidation ditches and can usually be incorporated

into other systems as well.

9-7

Previous Page

Previous Page