TM 5-852-5/AFR 88-19, Volume 5

(4) Attached growth systems. These include

ms = proportionality coefficient for sludge, use

trickling filters, rotating biological discs, and other

0.6 for sludge concentrations in range 0-

devices with plastic, rock or wooden media. Effec-

7 percent solids (higher concentrations

are difficult to spread on bed), in (EFd)-

tive treatment depends on maintaining a thin film of

IA = Air freezing (or thawing) index, EFd

liquid over the media. These units are susceptible to

freezing and must therefore be enclosed in a pro-

(use warmest winter of record for

tective structure. Criteria from TM 5-814-3/AFM

freezing calculations)

88-11, Vol.3, will be used for design, along with the

temperature coefficients given in table 9-3. The need

(1) Sludges with an undrainable jelly-like

for additional heat in the protective structure will

consistency will dewater immediately upon thawing

depend on the temperature of incoming waste-water

and then have a granular consistency.

and on the degree of treatment required.

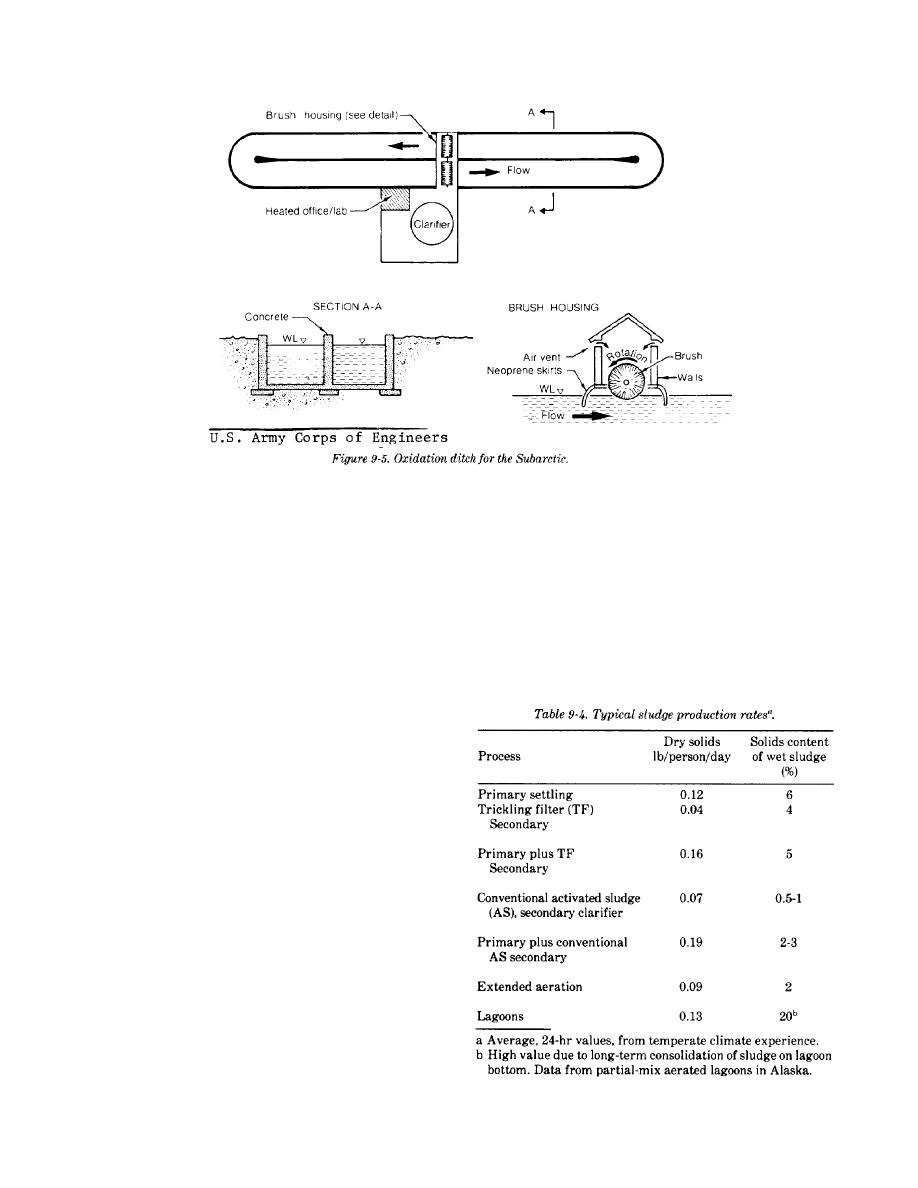

9-5. Sludge management.

Large-scale, conventional treatment facilities and

those operating in a heated environment can be

expected to produce sludge at rates similar to those

of conventional temperate zone practice. Typical

values for systems in use in the cold regions are

presented in table 9-4. Thickening, digestion, and

dewatering of sludge all follow temperate zone

practice as defined in TM 5-814-3/AFM 88-11,

Vol.3.

a. Freeze-thaw dewatering. Sludges from water

or waste water treatment operations can be flooded

onto conventional open sand drying beds in layers

and allowed to freeze. The depth of sludge that can

be frozen (or thawed) is calculated with:

X = ms (IA)

(eq 9-6)

where:

X = depth of sludge that can be frozen, inches

9-8

Previous Page

Previous Page