UFC 1-900-01

1 DECEMBER 2002

Initially, additional time will be required for contract development. Once a recycling

contract has been developed and accepted, future contracts for recycling can be readily

implemented and contract development is no longer a factor.

3-2.3 Recover (Time). Recovering building materials for reuse is a viable option when

time is not constrained. The time involved in handling, sorting, cleaning, cutting, and

selling second hand building materials is substantial and can undermine the feasibility of

salvage at a demolition job. Duration on-site depends on the extent of the recovery and

hand labor required to extract recoverable materials. Extra care and time must be taken

to reduce the chances of damaging the materials as they are removed. Separating and

sorting materials as they are recovered from the building will increase the total time for

on-site removal, but will produce higher quality materials and much higher financial

returns. References for deconstruction can also be used for determining the time

requirements for recovery. These references are included in the paragraphs below.

3-2.4 Deconstruct (Time). Relocating or removing the entire building intact and

panelized deconstruction, are rapid forms of deconstruction. However, manual

deconstruction is labor intensive and will naturally increase the overall duration of the

project. The time requirements for disassembly may vary between three to eight times

that of mechanical wrecking. Case studies conducted in the military and private sector

show that manual deconstruction proceeds at a rate of about 0.3 SF per man-hour for a

wood frame building. For example, a 3,600 SF typical wood frame WWII building, at 0.3

SF per man-hour, with a 10-person crew, requires roughly 3 weeks to manually

deconstruct. This figure includes handling, on-site processing and project management

and is consistent with R.S. Means productivity data.

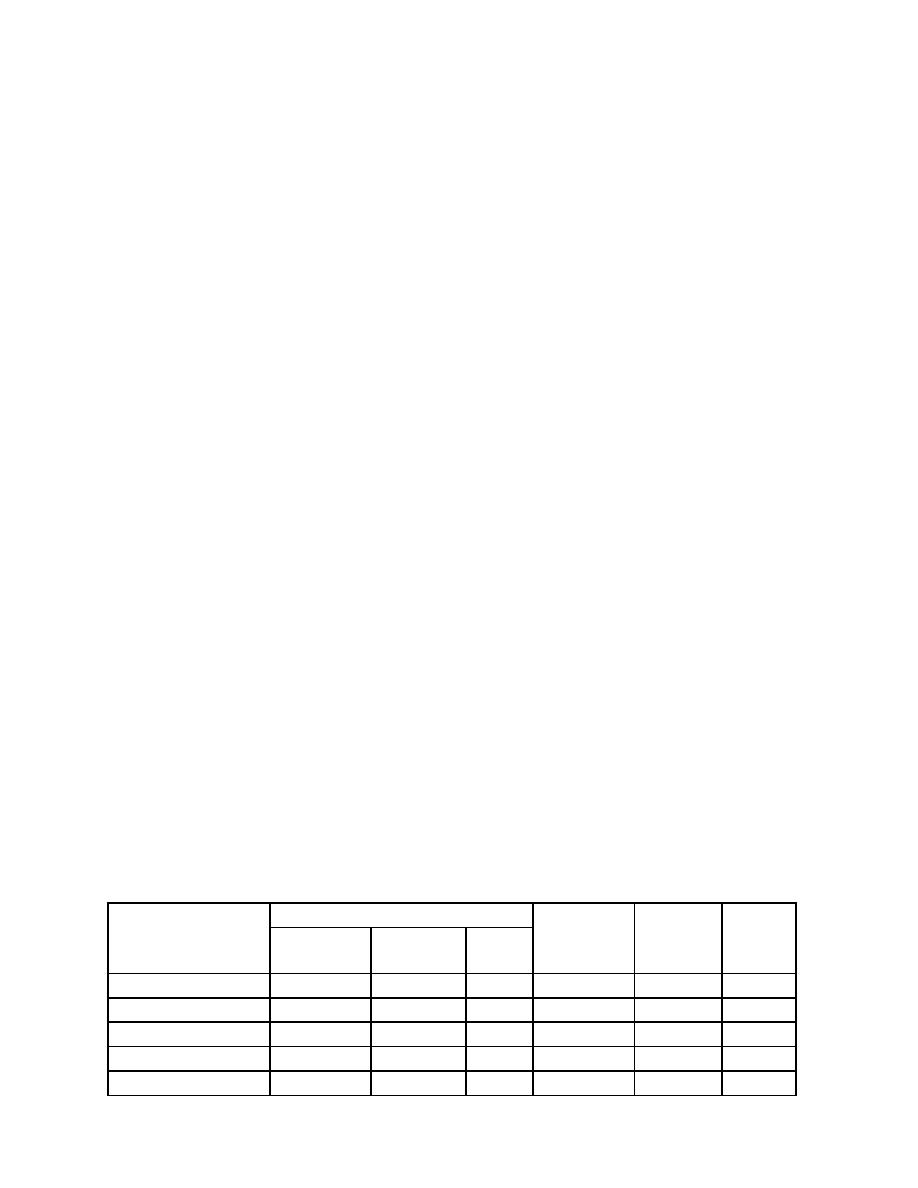

Table 3-4 lists labor hours recorded for the disassembly and salvage of components

from a 2,000 square foot building made up of four residential units that was

deconstructed as part of the Riverdale Case Study. The Riverside Case Study was a

multi-agency (EPA/NAHB/HUD) deconstruction project in Baltimore that implemented

pilot deconstruction.

These labor hours can be used in combination with more comprehensive references,

such as R.S. Means Building Construction Cost Data, Micro Computer-Aided Cost

Engineering Systems (MCACES), and a Job Order Contracting (JOC) handbook for

estimating deconstruction/demolition square foot costs.

Table 3-4. Labor Hours for Disassembly and Salvage of a 2,000 SF Building.

Tasks (hours)

Disassem Processi Supp Compone

Labor

Component

nt Total

Hours

Unit

bly

ng

ort

Interior

Doors, frames

5.75

5.25

11.0

0.55

EA

Trim, baseboards

4.75

5.0

9.75

0.19

LF

Cabinets

2.75

0.5

3.25

0.27

EA

Plumbing fixtures

7.75

1.75

9.5

0.59

EA

3-6

Previous Page

Previous Page