UFC 3-410-04N

25 October 2004

of the airflow. Construct hoods of noncombustible materials. Ensure the hoods do not

interfere with worker operations. In some cases, the exhaust hood may be utilized as a

safety guard. Refer to the ACGIH IV Manual, Chapter 10 for woodworking hood

designs. Modify the drawings as necessary to meet the specific equipment and process

requirements.

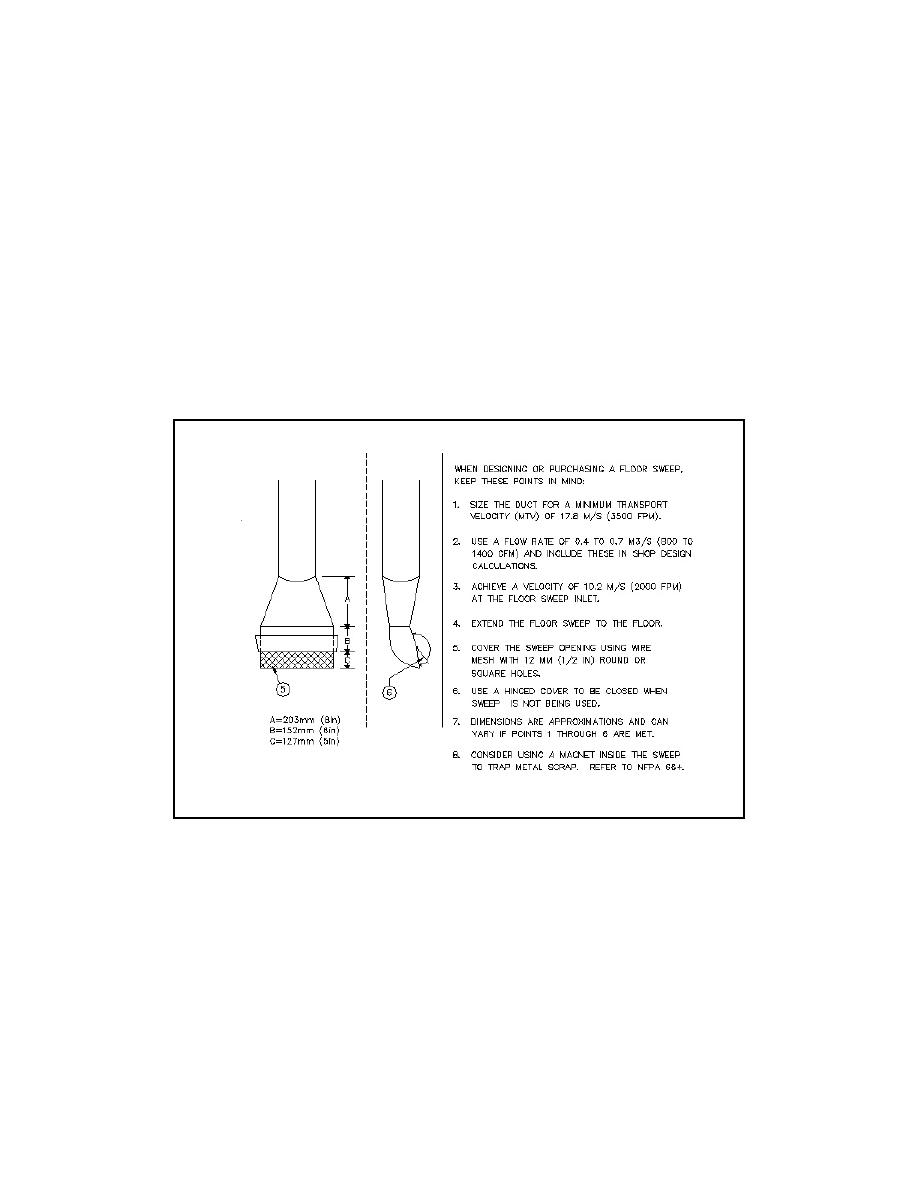

7-4.3

Floor Sweeps. If the design includes floor sweeps, include a means,

such as magnetic separators, to prevent scrap metal from entering the system. Figure

7-1 shows a basic floor sweep design. The floor sweep is only opened during shop

clean up. If the system design calculations indicate that, when opened, the floor sweep

provides a transport velocity of less than 17.78 m/s (3,500 fpm,) design the system to

include floor sweeps in the normally opened position without a hinged cover.

Figure 7-1. Floor sweep

7-4.4

Ductwork. See paragraph 2-4.1 for general ductwork design. See NFPA

664 for specific requirements on wood shop ductwork construction. Size the ductwork

to maintain a minimum transport velocity as specified in the ACGIH IV Manual, Chapter

10, Woodworking. Use only metal ductwork and conductive flexible hose. Bond and

ground all ductwork in accordance with NFPA 664. The ductwork must be designed on

the basis that all hoods and other openings connected to the system are open.

7-4.5

Blast Gates. Provide blast gates only for the specific purpose of

balancing the airflow. Do not use blast gates to isolate equipment from the exhaust

system with the intent to reduce the overall airflow requirement. When possible, install

blast gates on horizontal runs and orient the gate so the blade is on the top half of the

duct and opens by pulling the blade towards the ceiling. When possible, blast gates

7-2

Previous Page

Previous Page