UFC 3-410-04N

25 October 2004

c. Isolate the abrasive blasting rooms from other processes, functions

and activities, whenever possible. Place blasting rooms outside, away

from administration and other spaces. Protect the blasting room and

related equipment from rainwater and moisture intrusion. As a minimum,

put a roof or cover over the blasting room.

6-3.3.1

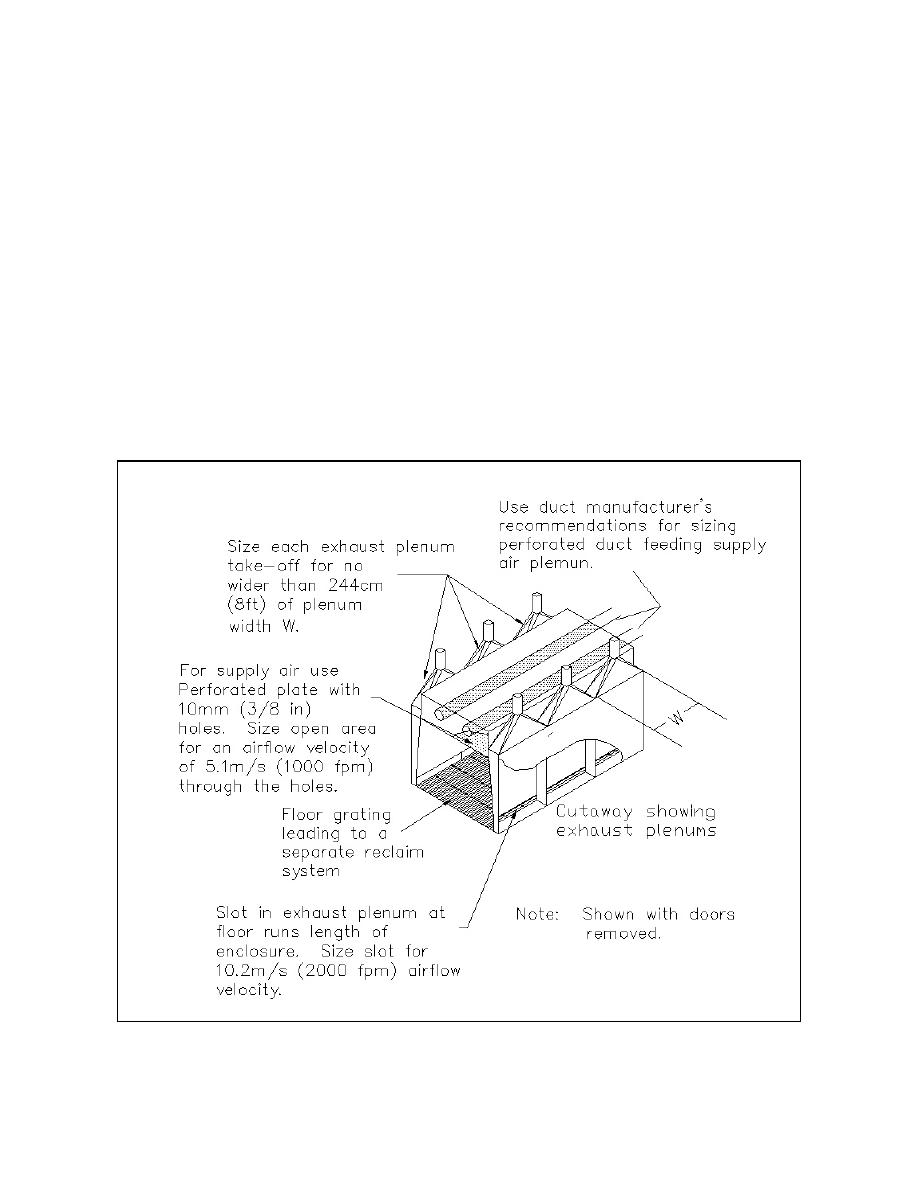

Downdraft. The downdraft design provides superior visibility. In addition,

a downdraft design is preferred since contaminated air is usually drawn away from the

worker's breathing zone. When more than one operator works in an enclosure,

contaminated air generated from one operation is less likely to migrate into the other

operator's breathing zone. Use a perforated plate with 9.53-mm (3/8-in) diameter holes,

as shown in Figure 6-1, to uniformly distribute the airflow over the entire cross-section of

the enclosure. Use a perforated duct inside the plenum to help evenly pressurize the

plenum.

Figure 6-1. Downdraft blast enclosure.

6-3.3.2

Crossdraft. Consider the work locations of operators when positioning

the replacement and exhaust air plenums. Do not allow any operator to blast upstream

of coworkers. Use a perforated plate with 9.53 mm (3/8-in) diameter holes; see Figure

6-2

Previous Page

Previous Page