UFC 3-410-04N

25 October 2004

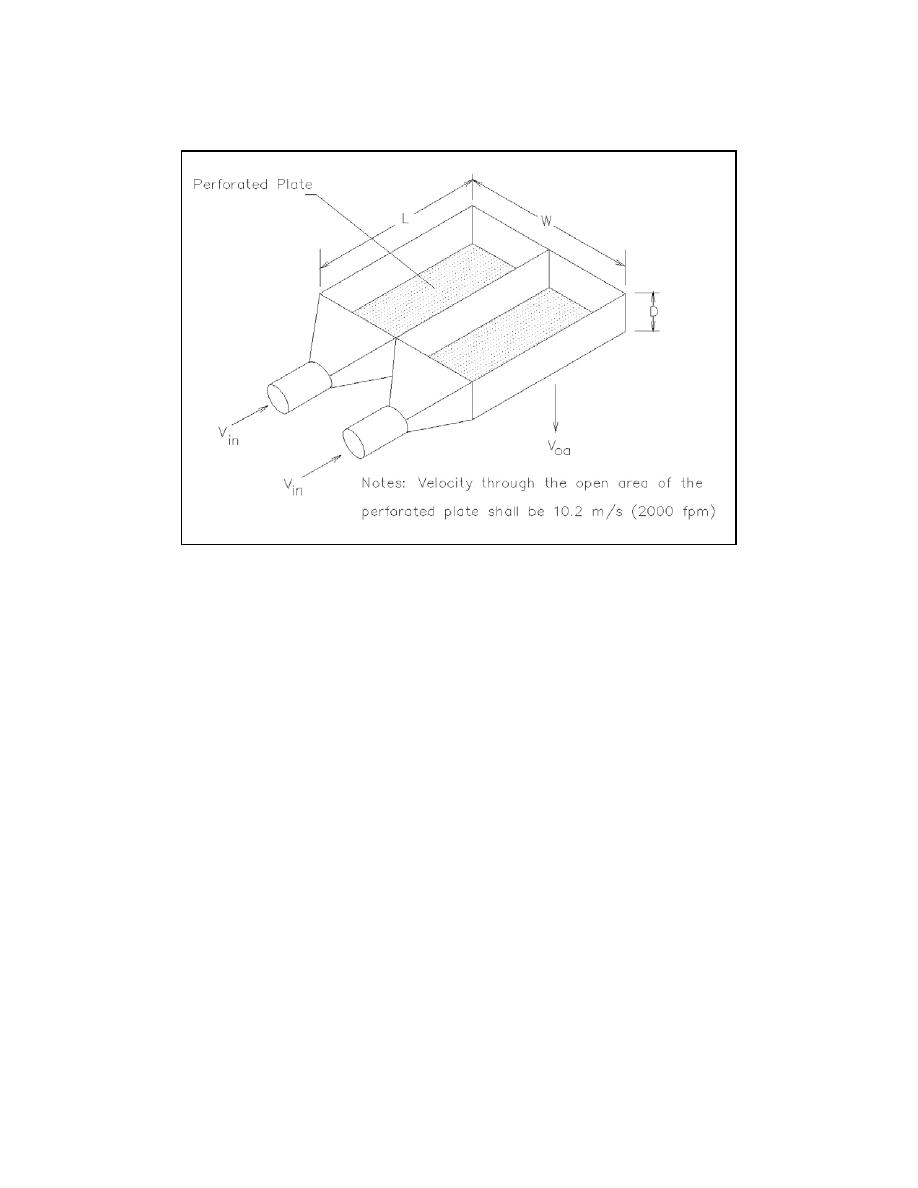

Figure 2-4. Plenum design without perforated duct.

2-4.5.3

Perforated Duct Design. Use perforated duct to evenly distribute the

flow of replacement air inside a plenum or use alone when ceiling height is greater than

4.58 m (15 ft). Manufacturers provide several different types and sizes of perforated

duct. Use recommendations from the manufacturer for duct design. The manufacturer

will not only recommend the size, shape, and type of the required perforated duct, but

also the location of the orifices and reducers to distribute the air properly.

2-5

CONTROLS. Provide industrial ventilation system controls and

associated alarms to ensure contaminant control, space specific balance and

conditioning, a safe and healthy work environment, and system malfunction notification.

2-5.1

Gauges and Sensors. Specify gauges and sensors to provide

continuous monitoring of system performance. The minimum requirements are:

2-5.1.1

Differential pressure sensors, with gauge readouts, across each

replacement air filter section. Set points on the gauge to trigger an alarm when the

pressure drops or gains across the filter exceed the manufacturer's recommended

value. A pressure drop occurs when there is a blow through a filter and a pressure gain

occurs when the filter gets loaded.

2-5.1.2

Operating light on replacement air system fan motor.

2-8

Previous Page

Previous Page