TM-5-855-4

horse-power for air movement. Blast closure devices, debris shields, and dirt traps in the supply and

exhaust ducts will increase the level of protection.

(2) Underground radiator vaults will have provisions to wash down the radiators and pump out

material deposited on the coil surfaces. The material poses no contamination problem for the cooling

liquid but does reduce thermal efficiency of the radiator coils.

(3) An average air velocity of 1,500 fpm through the core, as measured by an anemometer in front

of the core, is recommended. This air velocity causes a slight hum or noise, but the noise is not

objectionable.

b. The fan will be operated at the speed necessary to obtain the recommended 1,500 fpm air velocity but

will never be operated at more than 12,500 fpm speed when using a centrifugal type.

(1) For larger fan sizes the fan speed will fall below 1,150 rpm, the lowest recommended speed for

directly connecting the fan to the motor. Fan speeds below 1,150 rpm will require provisions for reducing

the electric motor shaft speed to the desired fan speed. For small installations using centrifugal type

fans, the fan will be directly connected to the motor. Specifically designed propeller-type fans will be

operated at higher speeds and direct-connected to electric motors running at 1,750 or 1,150 rpm.

(2) A centrifugal fan operating at a peripheral speed of 10,000 fpm is a source of noise. Sound

pressure levels will not exceed 85 dBA in occupied areas. If they do, the noise will be reduced by lowering

the fan speed, isolating the fan, or using inlet and outlet silencers. An average air velocity of 1,500 fpm

can be obtained using relatively large fans running at lower than 10,000 peripheral fpm. A large fan

running at a low speed is more practical than a small fan running at a high speed.

(3) Propeller-type fans require less power than centrifugal types. For best results they will be used as

a blower-type fan and will be located from 6 inches to 10 inches in back of the core and have a shroud.

Their cost, including installation, is generally greater.

(4) Forced draft produces more turbulence than induced draft, thus increasing the heat transfer

rate. Induced draft provides more uniform airflow and less turbulence, handles hot air, and requires

from 1 to 8 percent more fan horsepower.

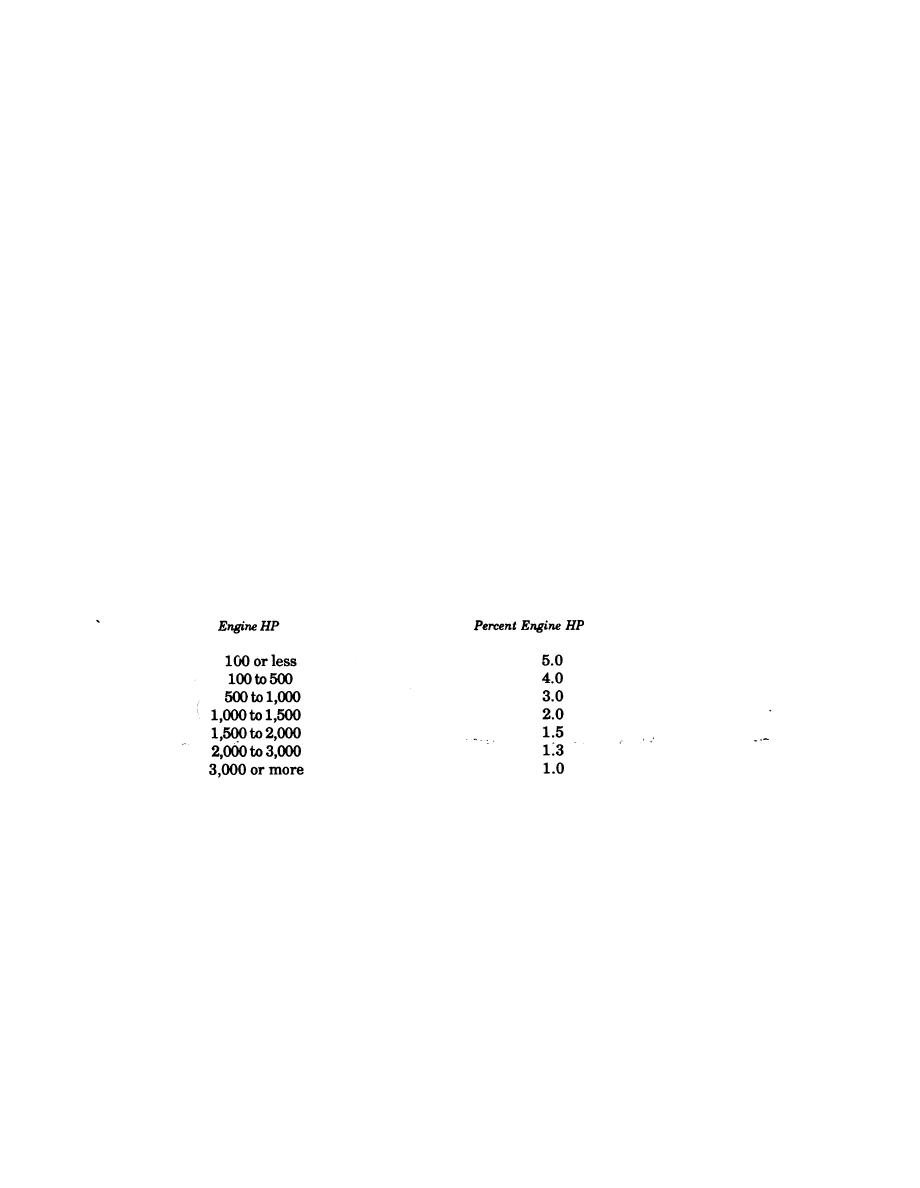

(5) Values for the average power required to drive engine radiator fans are given below as a

percent of the engine hp. These values are considered reasonable but may vary with coolant temperatures

and ambient air temperature.

(6) Two-speed motor drives are frequently used to save fan power when the maximum cooling

effect is not required, because power requirements decrease faster than the degree of cooling. At half-

speed, fans will produce 50 percent or more of total cooling capacity but will require only 20 percent of the

power needed for full-speed operation. Control of airflow is another method of modulating the cooling

affect. Use of two-speed motors is preferable if the heat dissipation requirements frequently vary.

5-15

Previous Page

Previous Page