TM 5-809-6/AFM 88-3, Chap. 6

Handbook by Gaylord & Gaylord for circular steel stacks.

conveying a gas of different specific gravity than atmospheric

Components will be proportioned so that resonance due to

conditions and to temperature differential stresses caused by

vortex shedding at low wind velocities is avoided. For duct

an uneven temperature distribution within the stack. See also

of rectangular cross section, structural design will be in

ASCE Design and Construction of Steel Chimney Liners.

(1) Reinforced concrete stacks. Reinforced concrete

accordance with the AISI Design of Plate Structures, Design

of Welded Structures by Blodgett, and applicable portions of

stacks will be designed in accordance with ACI 307.

(2) Aluminum stacks. If constructed of aluminum,

the American Institute of Steel Construction (AISC)

Specification for Structural Steel Buildings Allowable Stress

design of stacks will follow similar design guidance and

Design and Plastic Design that relates to plate girders.

general references given for design of steel stacks.

(3) Steel stacks.

Design will include a determination of plate thickness

(a) Design of steel stacks will be in accordance with

required to resist flexural loading, the size and spacing of

stiffeners, the size and location of internal bracing, and

the AISC Specification for Structural Steel Buildings

additional plate thickness and features which may be

Allowable Stress Design and Plastic Design; Structural

required if the duct is designed as a spanning box girder.

Engineering Handbook by Gaylord & Gaylord; SMACNA

b. Stacks. In addition to maximum loadings, stacks will

Guide for Steel Stack Design and Construction; and ASME

be designed to resist the effects of vortex shedding or

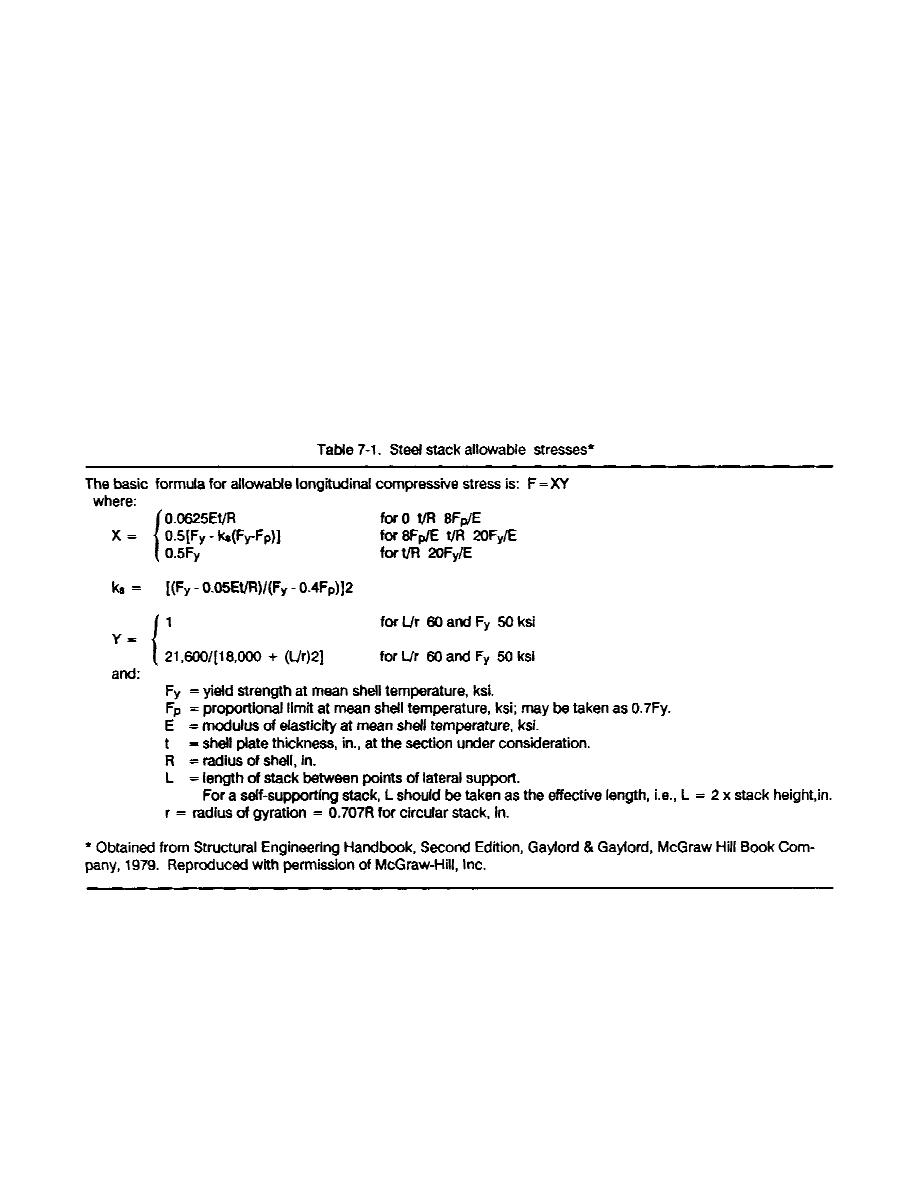

STS-1. Allowable stresses will be in accordance with table

fluttering caused by steady wind. Stack designs will consider

7-1. The allowable stress is for a design condition of dead

pressure differential stresses caused by virtue of the stack*s

load combined with either seismic or wind loads.

(b) Shell thickness will be at least 1/4 inch for lined

bolt hole areas) will be used to determine actual stresses.

stacks and 5/16 inch for unlined stacks. The computed shell

Allowable stresses for parts other than the shell plate will be

thickness will be increased by 1/16th inch to allow for

in accordance with AISC Specification for Structural Steel

possible corrosion. The net section area (gross area minus

Buildings Allowable Stress Design and Plastic Design.

7-2

Previous Page

Previous Page