CEMP-E

TI 809-26

1 March 2000

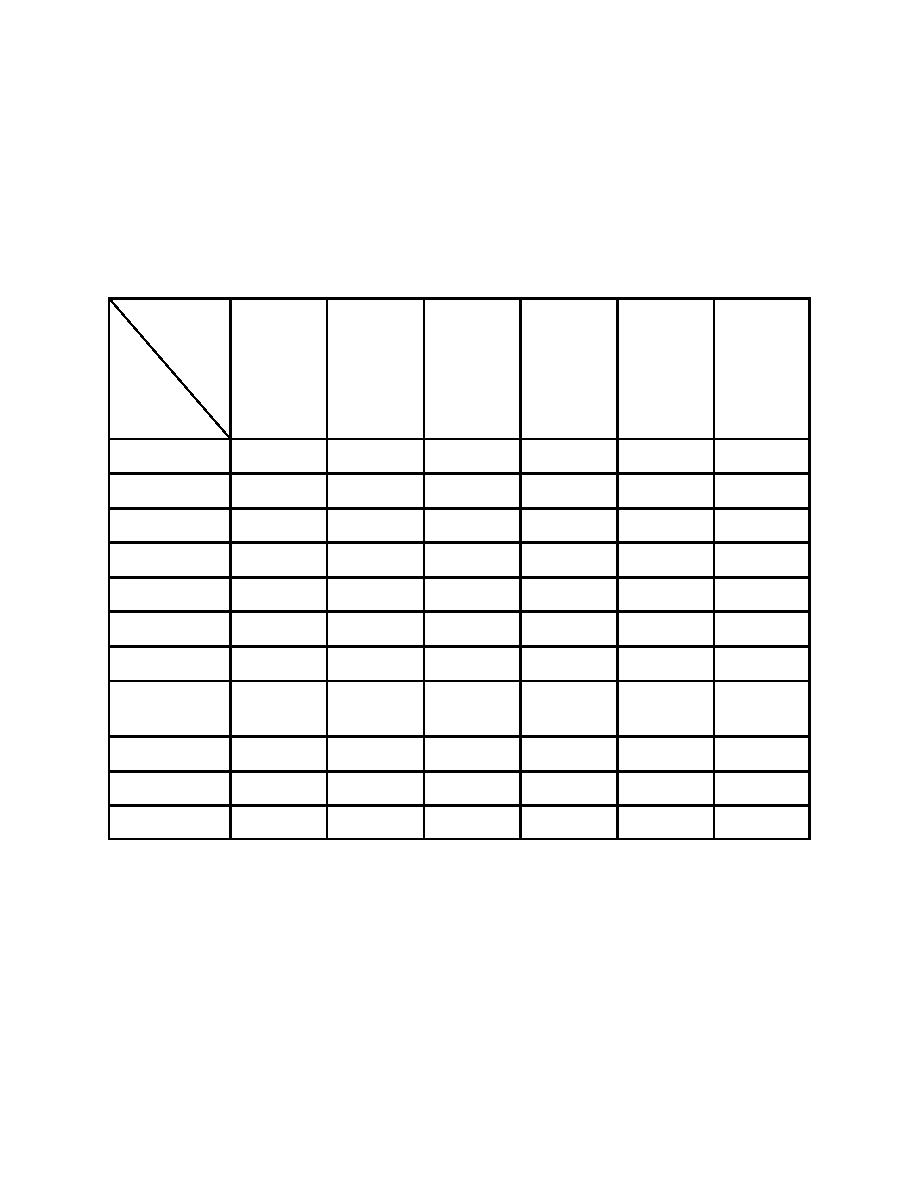

Table 4-3. Chemical Requirements for Sample Structural Steels

Table

(heat analysis, %, maximum, unless range is provided)

(Refer to ASTM specifications for complete information, including applicable

thickness ranges, grades, types, combinations of elements, etc.)

Steel

A572

A572

A36

grade 50

grade 50

A588,

A992

A852

(shapes)

(shapes)

(shapes)

grade B

Compositio

Type 1

Type 2

n

C

0.26

0.23

0.23

0.23

0.20

0.19

Mn

---

1.35

1.35

0.50-1.50

0.75-1.35

0.80-1.35

P

0.04

0.04

0.04

0.035

0.04

0.035

S

0.05

0.05

0.05

0.045

0.05

0.04

Si

0.40

0.40

0.40

0.40

0.15-0.50

0.20-0.65

Cu

#

#

#

0.60

0.20-0.40

0.20-0.40

V

---

0.01-0.15

0.11

0.01-0.10

0.02-0.10

Co

0.005-

---

---

0.05

---

---

0.05

Ni

---

---

---

0.45

0.50

0.50

Cr

---

---

---

0.35

0.40-0.70

0.40-0.70

Mo

---

---

---

0.15

---

---

Shapes composition limits are listed for sections up to 634 kg/m (426 plf).

# minimum 0.20% when specified

3. PROPERTY ENHANCEMENTS FOR STRUCTURAL STEELS.

a. Yield to Ultimate Strength Ratio. AISC design equations assume some margin in structural steel

from the point of yielding to the point of fracture to allow for the redistribution of stress. Some structural

steels have been produced with Fy:Fu ratios as high as 0.95, considerably higher than that considered by

4-9

Previous Page

Previous Page