TM 5-809-3/NAVFAC DM-2.9/AFM 88-3, Chap. 3

CHAPTER 4

DESIGN FOR CRACK CONTROL

4-1. Introduction. This chapter provides criteria

to limit the shrinkage of the unit in the wall to a

and methods to control cracking in concrete and

level sufficient to control cracking. Masonry units

brick masonry walls, composite walls, and an-

delivered and stored at the site should be protected

chored veneer wythes. Normally, cracking in ma-

from rain and snow, which would increase their

sonry results from shrinkage in concrete masonry

moisture content.

b. Control joints. To control shrinkage cracking,

unit construction and expansion in brick masonry

unit construction. Uncontrolled cracking is a sig-

control joints should be placed and spaced to divide

nificant problem in the masonry industry. Cracking

walls or wythes into a series of rectangular panels.

is controlled by proper placement of joints, proper

Control joints should also be placed in areas of high

material selection, and by steel reinforcement, or a

stress concentration where cracking is most likely

combination thereof. Although the cracking of

to occur. Normal spacing and desirable locations

masonry is not normally a structural design

for control joints are noted in table 4-1. Control

consideration, the locations of joints placed in

joints should not be located at openings due to

masonry walls to control cracking can affect the

construction and performance problems and

structural performance of the wall. The crack

minimum reinforcement requirements. For struc-

control criteria contained herein is based on loca-

tural walls, the minimum reinforcement around

tions where environmental changes (temperature

openings is given in chapter 5. For non-structural

and moisture fluctuations) are large. When sup-

partitions, the minimum reinforcement around

ported by successful local practice; the designer

openings will consist of one No. 4 bar at each side

may deviate from the joint locations, material

and at the top and bottom of each opening.

selections, and reinforcement criteria contained in

Reinforcing bars will extend 24 inches beyond the

this manual. Locations and details of control joints,

edge of the opening.

bond beams, brick expansion joints, and structural

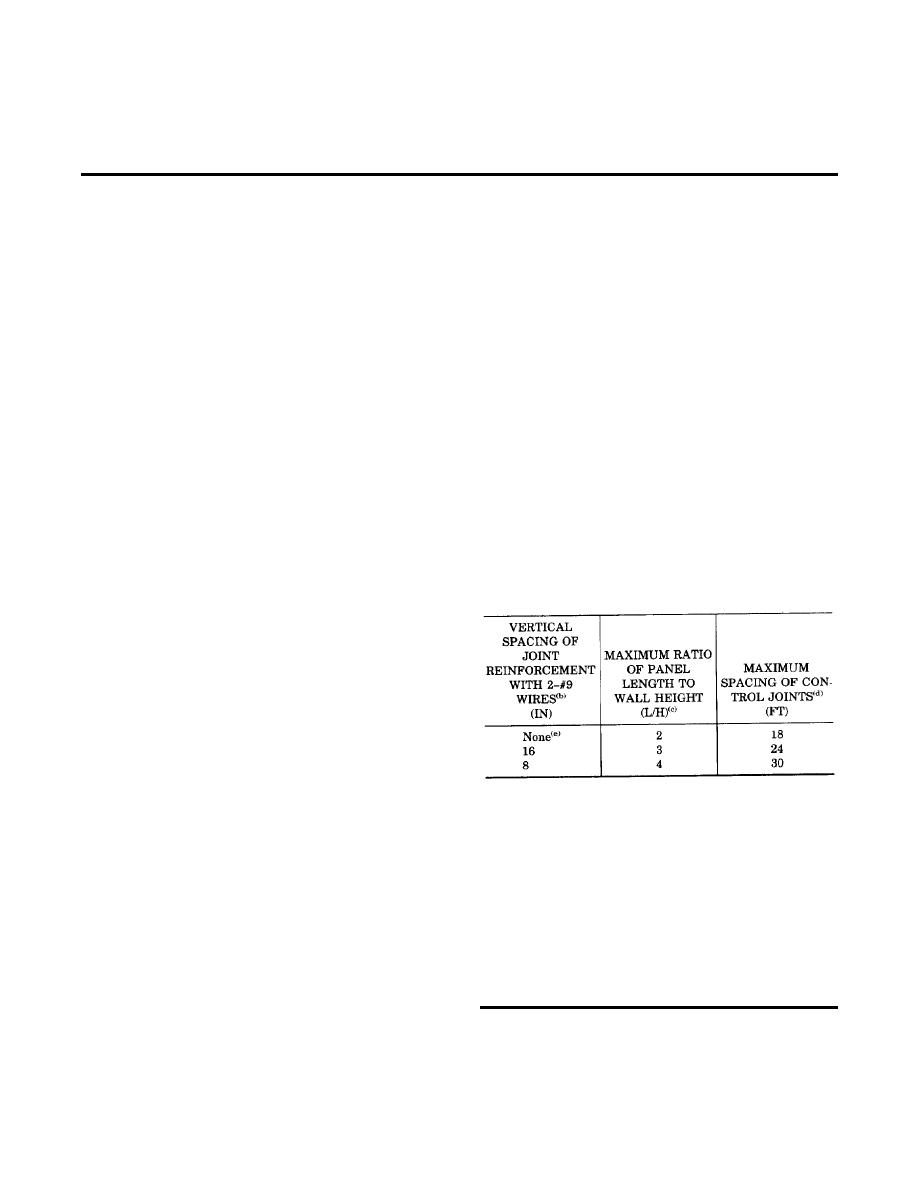

Table 4-1. Recommended control joint spacing (a)

expansion joints will be shown on the contract

drawings on both plan and elevation views.

4-2. Concrete masonry walls. Cracking of con-

crete masonry walls is generally caused by shrink-

age due to moisture loss in the units. Methods used

to control cracking in concrete masonry structures

are materials specifications to limit the drying

shrinkage potential, control joints (CJ*s) to

accommodate movement, and reinforcement to

(a)

based on moisture-controlled, type I, concrete masonry in

control crack size and location.

intermediate humidity conditions (ASTM C 90). The designer should

a. Material specifications. The type of unit to

adjust the control joint spacing for local conditions. The recommended

be used in all construction will be ASTM C 90,

spacing may be increased 6 feet in humid climates and decreased 6

moisture controlled, type I, units. Type II units,

feet in arid climates.

which have no moisture control, will not be used.

(b)

Joint reinforcement will he cold-drawn deformed wire with a

The ASTM C 90 standard provides limits on

minimum 9 gauge longitudinal wire size.

(c)

L is the horizontal distance between control joints. H is generally the

moisture content for moisture controlled units

vertical distance between structural supports.

depending on linear shrinkage potential and aver-

(d)

The spacing will be reduced approximately 50% near masonry

age annual relative humidity at the place where the

bonded corners or other similar conditions where one end of the

units will be installed. For example, in an area

masonry panel is restrained.

where the average annual relative humidity is 50 to

(e)

Not recommended for walls exposed to view where control of

75 percent and the linear shrinkage potential of the

cracking is important.

unit is 0.03 percent, the units should be delivered to

Recommended control joint locations

the site with a maximum moisture content of 40

a. At regular intervals as noted in table above.

b. At changes in wall height or thickness. (This does not include

percent. Units with a linear shrinkage potential of

at pilasters.)

0.045 to 0.065 percent, delivered to the same site,

c. Near wall intersections in "L", "T", and "U" shaped buildings

should have a maximum moisture content of 30

at approximately 50% of the spacing required above.

percent. The purpose of this part of the standard is

d. At other points of stress concentration.

4-1

Previous Page

Previous Page