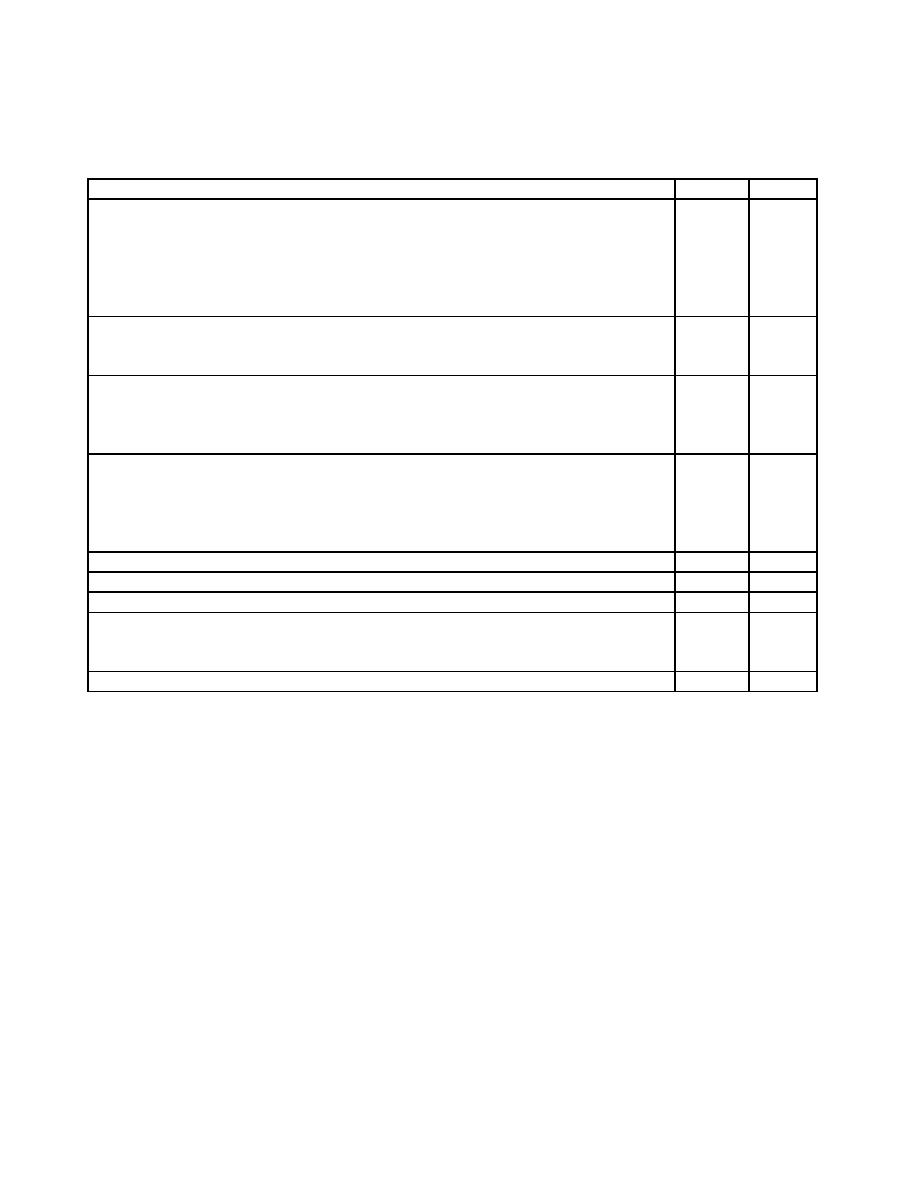

Table 10-2: Mechanical and Electrical Components Coefficients

Mechanical and Electrical Component or Elementc

ap a

Rp b

General Mechanical

Boilers and furnaces

1.0

2.5

Pressure vessels on skirts and free-standing

2.5

2.5

Stacks

2.5

2.5

Cantilevered chimneys

2.5

2.5

Other

1.0

2.5

Manufacturing and Process Machinery

General

1.0

2.5

Conveyors (nonpersonnel)

2.5

2.5

Piping Systems

High deformability elements and attachments

1.0

3.5

Limited deformability elements and attachments

1.0

2.5

Low deformability elements and attachments

1.0

1.25

HVAC System Equipment

Vibration isolated

2.5

2.5

Non-vibration isolated

1.0

2.5

Mounted in-line with ductwork

1.0

2.5

Other

1.0

2.5

Elevator Components

1.0

2.5

Escalator Components

1.0

2.5

Trussed Towers (free-standing or guyed)

2.5

2.5

General Electrical

Distributed systems (bus ducts, conduit, cable tray)

1.0

3.5

Equipment

1.0

2.5

Lighting Fixtures

1.0

1.25

a A lower value for ap is permitted provided a detailed dynamic analysis is performed which justifies a lower limit.

The value for ap shall not be less than 1.00. The value of ap = 1 is for equipment generally regarded as rigid or

rigidly attached. The value of ap = 2.5 is for flexible components or flexibly attached components. See Chapter 2 of

FEMA 302 for definitions of rigid components and flexible components, including attachments.

b Rp = 1.25 for anchorage design when component anchorage is provided by expansion anchor bolts, shallow

chemical anchors, or shallow low deformability cast-in-place anchors or when the component is constructed of

nonductile materials. Powder-actuated fasteners (shot pins) shall not be used for component anchorage in Seismic

Design Categories D, E, or F. Shallow anchors are those with an embedment length-to-diameter ratio of less than

8.

c Components mounted on vibration isolation systems shall have a bumper restraint or snubber in each horizontal

direction. The design force shall be taken as 2FP.

10 4

Previous Page

Previous Page