UFC 3-280-04

17 DEC 2003

C-2.3

Establish Effluent Requirements and Confirm Need For Filtration. When-

ever the effluent suspended solids requirement is 30 mg/L or above, consider use of

sedimentation in lieu of filtration; this gives the same effect with less maintenance. Con-

sider what the effect on the suspended solids may be. From experience at other sites

and discussions with filter suppliers, install a downflow continuous backwashing filter to

prevent exceeding the suspended solids limit.

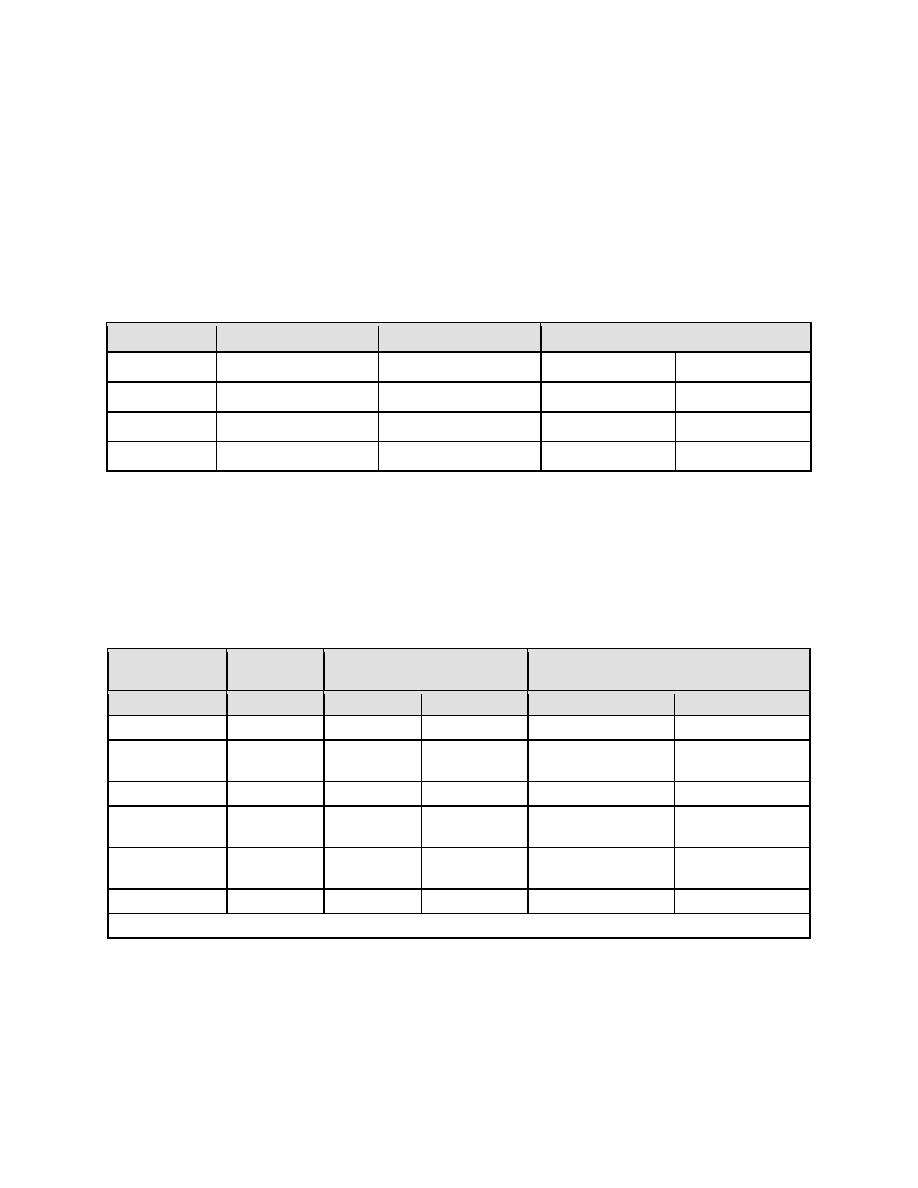

Table C-2. Suspended Solids Removal Requirements

at 12 L/s (190 gpm) = 1,036,800 L/day (273,900 gpd)

Effluent Standard

Influent

Removal Requirement

mg/L

10

100

90

90%

kg/day

10.368

103.680

93.312

90%

lb/gal.

0.000083

0.000834

0.00075

90%

lb/day

22.86

228.56

205.7

90%

C-2.4

Develop the Design Basis. Conversion units for filter loading

1 L/m2s = 1.473 gpm/ft2

1 gpm/ ft2= 0.679 L/m2s

Table C-3. Performance Capabilities

Particle

Application

Loading Rates

TSS [mg/L]

Sizes

[L/m2 s]

[gpm/ft2]

[microns]

Influent

Filtrate

Algae removal

912

22.7

34

20150

120

Metal

912

24

36

20100

25

hydroxides

Mill scale

912

27.5

311

20250

510

Phosphorus

912

23.4

35

20100

510

removal

10100

0.10.5

Surface water

912

24

36

[NTU]

[NTU]

direct filtration

Tertiary filtration

912

23.4

35

20150

110

Reference: Vendor B internet catalog

Determine filter size based on flow rate and hydraulic loading. Select a load-

ing rate for preliminary design. Table C-3 gives generally acceptable loading rates listed

by Vendor B for selected water treatment applications. For the applications given, the

maximum hydraulic loading varies from 2.7 to 7.5 L/m2s (4 to 11 gpm/ft2); the minimum

hydraulic loading is 2 L/m2 s (3 gpm/ft2) for all, with a typical rate of 4.1 L/m2s (6

gpm/ft2). Relatively little flexibility is available in sizing the unit because continuous

C-8

Previous Page

Previous Page