UFC 3-280-04

17 DEC 2003

5-3.2.2.2 Cartridge filters generally come as disposable pleated filters, where filter ele-

ments fit into a cylindrical container or housing. These filters come in 500 mm (20 in.) to

1500 mm (60 in.) lengths, with diameters on the order of 150 mm (6 in.), depending on

the style and manufacturer. They are typically installed in parallel to provide more sur-

face area. To determine how much filter area may be required for a particular operation,

the designer must first know the system flow rate. Most filter elements have throughputs

of 0.1 (L/min.)/m2 to 1 (L/min.)/m2 (0.254.0 gpm/ft2). Therefore, the number of filters

required can be calculated using the following equation:

Q

N=

J ( A)

where:

N

=

number of filter units required

Q

=

system flow rate (gpm)

flow density (surface loading) through the filter medium (gpm/ft2)

J

=

surface area available in each unit (ft2).

A

=

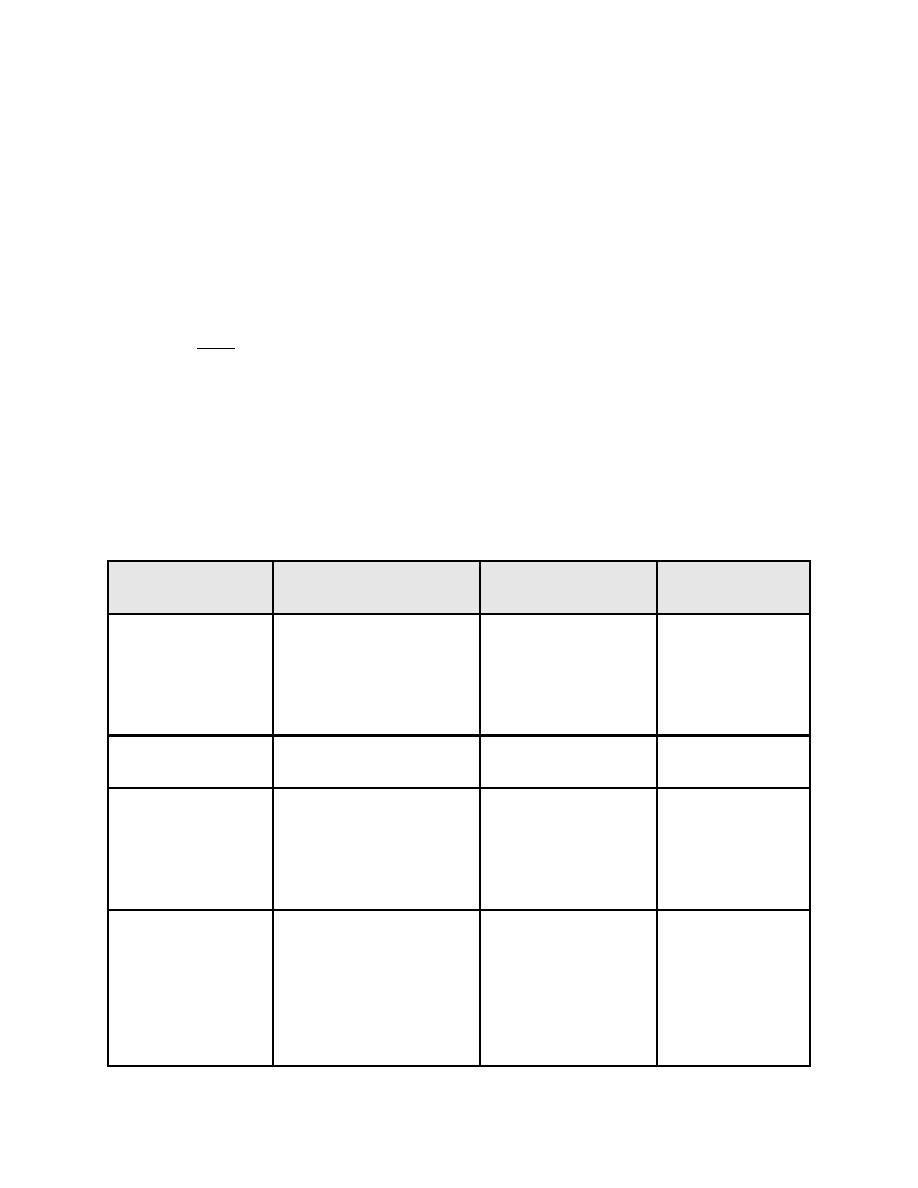

Table 5-7. Chemical Resistance Chart

Material

Resistance

Max Permissible

Max Permissible

Temp. (Water)

Temp. (Water)

Constant

Short-Term

Polyvinyl Chloride

Resistance to most

60 degrees C

60 degrees C

(PVC, UPVC)

solutions of acids, alkalis,

140 degrees F

140 degrees F

and salts and organic

compounds miscible with

water. Not resistant to

aromatic and chlorinated

hydrocarbons.

Chlorinated Polyvinyl

Can be used similarly to

90 degrees C

110 degrees C

Chloride (CPVC)

PVC but at increased

195 degrees F

230 degrees F

temperatures

Polypropylene (PP)

Resistant to water solutions

60 degrees C

80 degrees C

of acids, alkalis, and salts,

140 degrees F

175 degrees F

as well as to a large

number of organic

solvents.

Unsuitable for concentrated

oxidizing acids.

Polyvinylidene

Resistant to acids, solutions

90 degrees C

110 degrees C

(PVDF)

of salts, aliphatic, aromatic,

195 degrees F

130 degrees F

and chlorinated

hydrocarbons, alcohols,

and halogens.

Conditionally suitable for

ketones, esters, ethers,

organic bases, and alkaline

solutions.

5-33

Previous Page

Previous Page