UFC 3-280-04

17 DEC 2003

rials compatibility. While these tables are a generic guide to compatibility, corrosion

handbooks, field experience, and vendor literature should be reviewed to determine

compatibility with specific known compounds and characteristics of the waste stream.

Additional material compatibility information is contained in EM 1110-1-4008.

5-3.2.2 Configuration. Cartridge assemblies are units that contain one or more re-

placeable filter elements. The housings are constructed of material that is compatible

with the system operating pressure. Typical materials of construction include PVC and

stainless steel.

5-3.2.2.1 Filters are selected based on the desired particulate effluent quality and com-

patibility with the waste stream to be treated. Where high effluent quality, low particle

counts (i.e., number of particles remaining after filtration with a specified micron rating),

or removal of sub-micron particles is required, the filter pore size can be staged in se-

ries with progressively finer removal ratings to minimize the cost of the more expensive

sub-micron particulate filters. Most often, the method for selecting filter sizes for staging

is determined in the field. Alternatively, filtration rates using multiple pore size mem-

branes can be tested in the laboratory prior to field-testing.

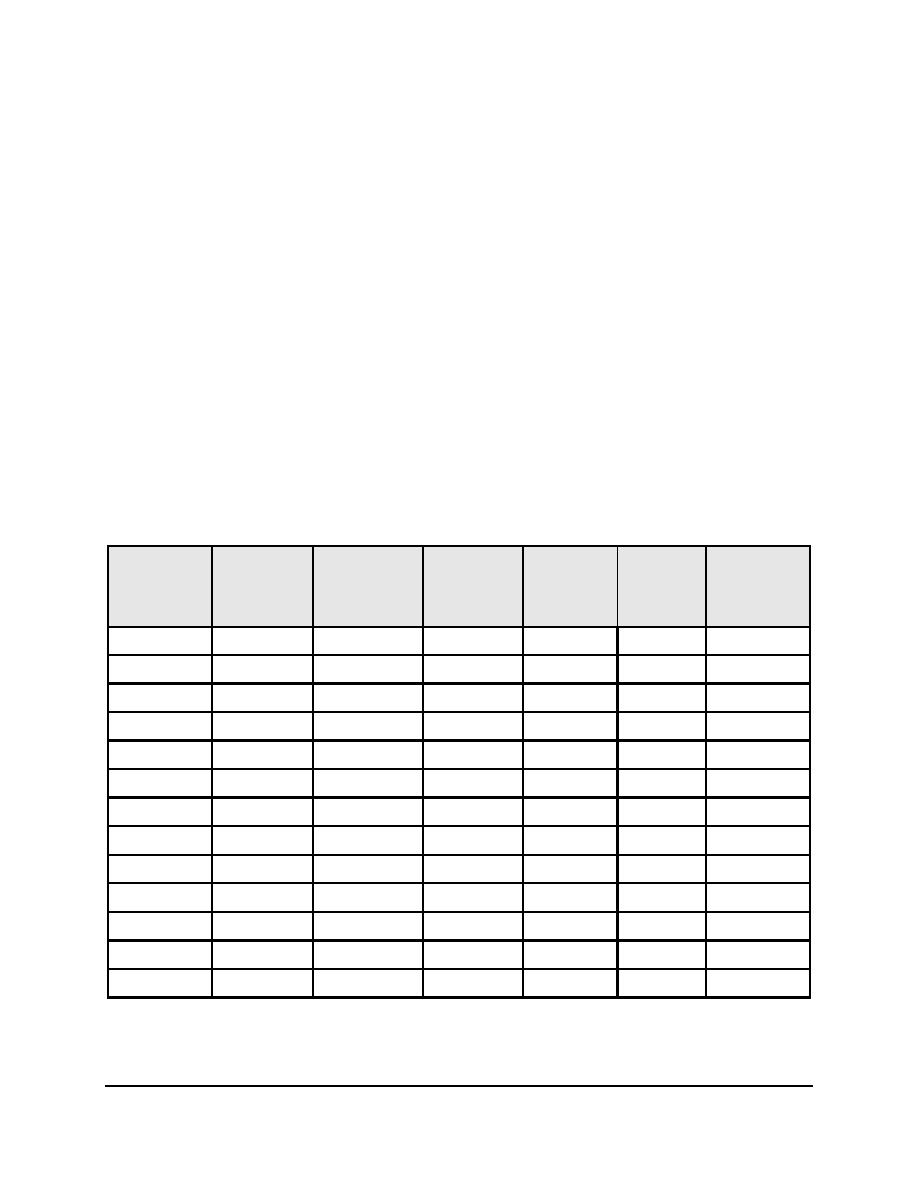

Table 5-6. Characteristics of Filter Materials

Maximum

Operating

Generic

Abrasion

Resistance to

to Oxidizing

Temperature,

Name

Acids

to Alkalis

to Solvents

Agents

Degrees C

(Degrees F)

Acetate

G

F

P

G

G

99 (210)

Acrylic

G

G

F

G

E

150 (300)

Glass

P

E

P

E

E

316 (600)

Metallic

G

varies

varies

varies

varies

varies

Modacrylic

G

G

G

G

G

82 (180)

Nylons

E

F-P

G

F-P

G

107 (225)

150 (3002)

Polyester

E-G

G

G-F

G

G

74 (1653)

Polyethylene

G

G

G

F

G

Polypropylene

G

E

E

G

G

121 (250)

Rayon

G

P

F-P

F

G

99 (210)

Saran

G

G

G

F

G

72 (160)

Cotton

G

P

F

G

E-G

99 (210)

288 (5504)

Fluorocarbons

F

E

E

E

G

Symbols have the following meaning: E = excellent; G = good F = fair; P = poor.

1. degree C = (degree F 32)/1.8; K = (degree F + 459.7)/1.8

2. Low-density polymer. Up to 230 degrees F, for high-density.

3. Heat-set fabric; otherwise lower.

4. Requires ventilation because of release of toxic gases above 400 degrees F.

5-32

Previous Page

Previous Page