UFC 3-280-04

17 DEC 2003

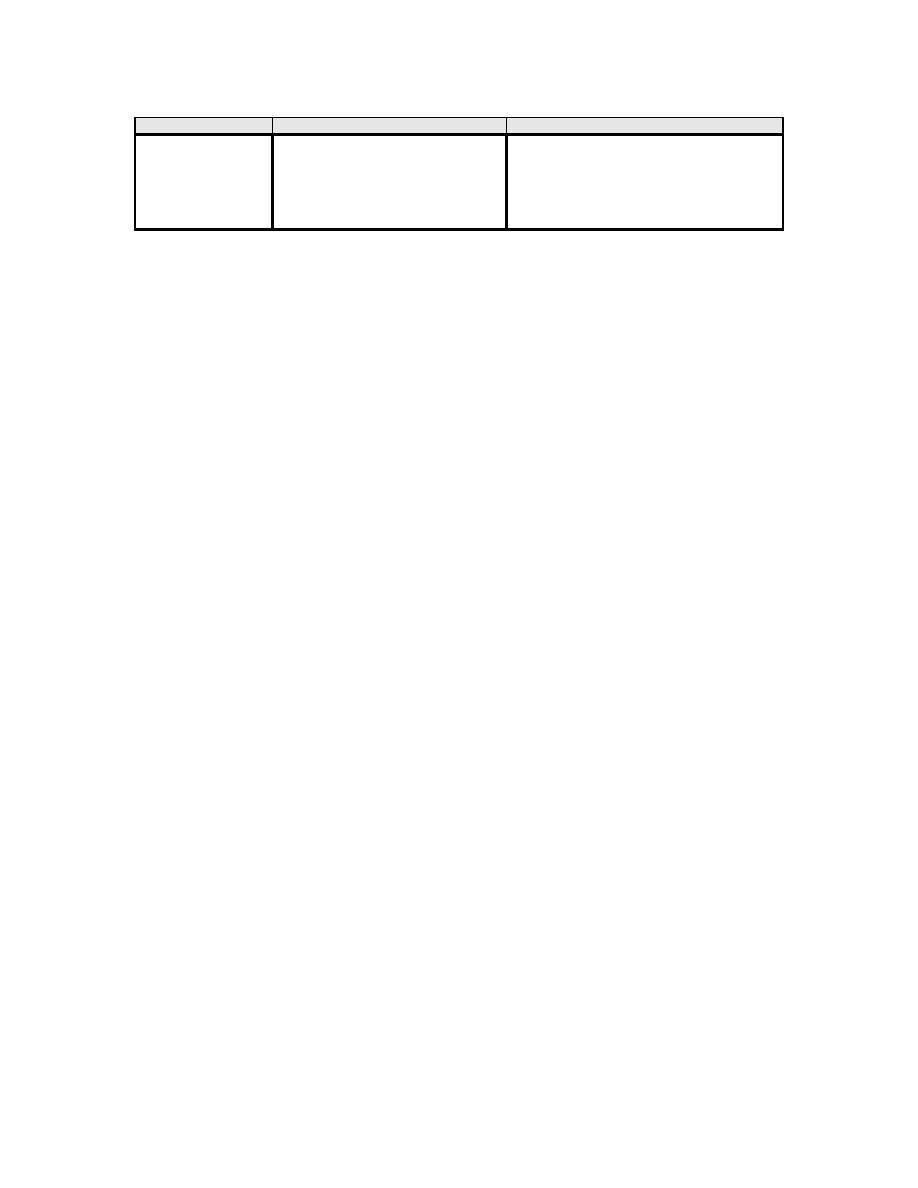

TYPE

ADVANTAGES

DISADVANTAGES

Plenum with porous

Excellent water distribution

Integral air-scour cannot be used

plates

No gravel layers needed

Filter box is deeper because of plenum

History of damaged plates

Little, if any, competitive market

Usually not recommended for wastewater

filtration

Source: Monk and Willis (1987)

Considerations in selecting an underdrain system include the size of the

underdrain, depth of the gravel layer, head loss during backwash, and material of con-

struction. The size of the underdrain will affect the depth of the filter box. The gravel

layer depth depends on the orifice size and spacing. Orifice size will greatly affect head

loss during backwash. The underdrain should be constructed of a material that will be

resistant to any contaminants in the water to be filtered.

Concrete filters are not generally used for flows less than 12 L/s (200 gpm).

Package systems used for low-flow applications will generally have standard under-

drains designed for the system. The manufacturers will provide guidance on whether

the particular application requires a different underdrain system.

5-1.2.10 Number of Cells. The number of filtration cells must be sufficient to assure

that the backwash flow rates do not become excessively large and that when one filter

cell is taken out of service for backwashing, routine maintenance, or repairs, the loading

on the remaining cells is within acceptable design criteria. The number of cells should

be kept at a minimum to reduce the cost of piping and construction. After peak filtration

and plant flow rates are established, the number of cells should be determined based

on total required surface area and space, and cost. Where multiple cells are specified,

the number of cells should be based on one cell being out of service at all times. Usu-

ally, the minimum number of cells is two, with four often recommended. For package

pressure filter systems, it is common to size the system with three cells, anticipating that

the design load through two cells will be exceeded for short periods of time while the fil-

trate from those two cells is used to backwash the cell requiring cleaning. For some low-

flow HTRW applications and continuous backwash systems, one cell may be sufficient if

it is acceptable to interrupt filtration (e.g., shut off recovery wells or increase equaliza-

tion storage) for backwash or maintenance.

5-1.2.11 Filter Size. Generally, the surface area required is based on the peak filtra-

tion and peak flow rate. Bed depth, filtration rate, head loss, and filter run length also

help determine the required filter size. Capital and operating costs must also be consid-

ered in designing the filter. The filter box must be large enough to house the media, un-

derdrain, any control mechanism, and troughs. Additionally, the filter box size will be, in

part, determined by the backwash requirements (the bed expands during backwash)

and control system.

5-1.2.12 Valves and Piping. The necessary valves and piping are for influent flow

control, effluent flow control, and the backwash cycle. Additionally, washwater troughs

must be designed.

5-12

Previous Page

Previous Page