UFC 3-280-04

17 DEC 2003

filter media with the filtered water. For conventional systems, a layer of gravel is often

placed between the media and the underdrain to aid in preventing media loss. The prin-

cipal consideration in underdrain design is the uniform distribution of backwash water.

Some common underdrain systems include pipe laterals with orifices or nozzles; ce-

ramic or plastic block laterals with holes, nozzles, or porous plates; lateral T-Pees; ple-

num, precast, or monolithic concrete, with holes, nozzles or porcelain spheres

(Wheeler-type); plenum with porous plates; and porous plates in ceramic block laterals.

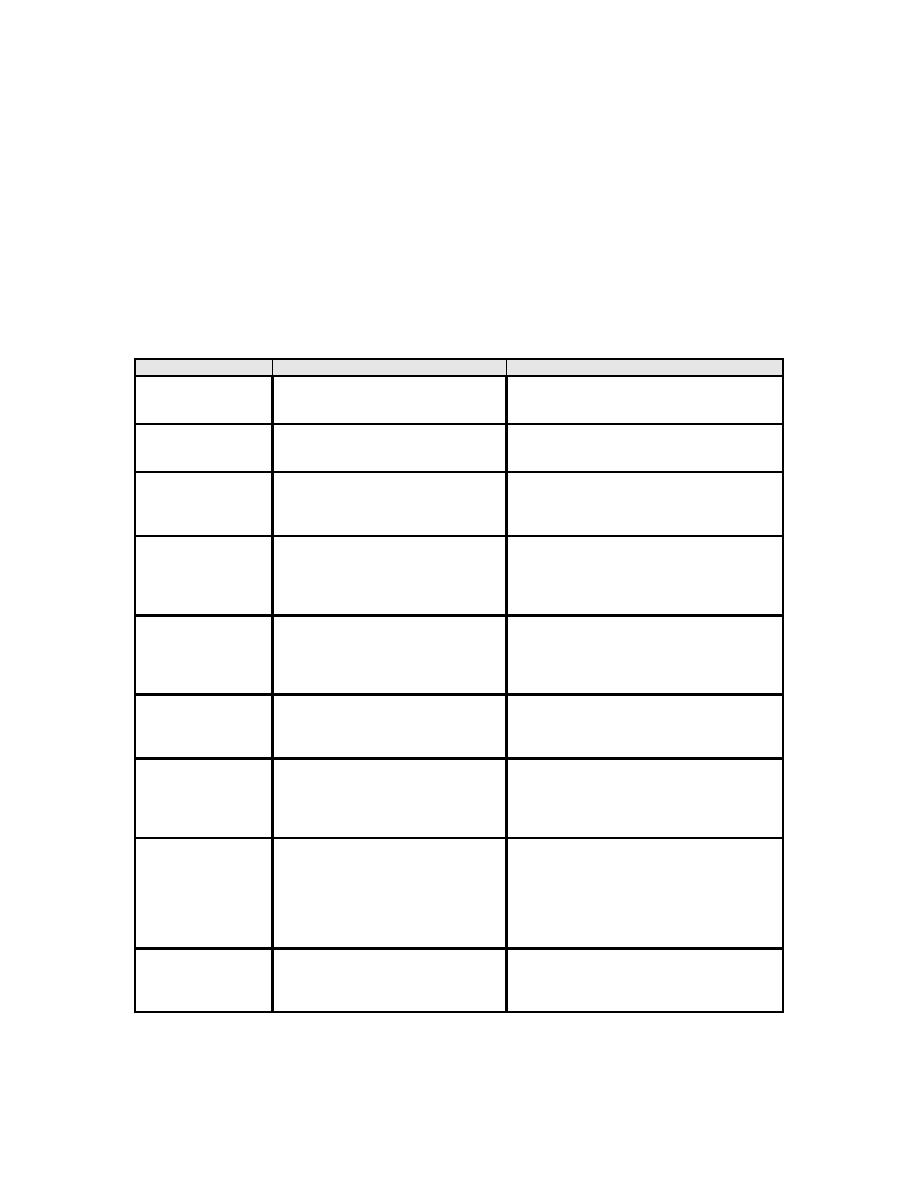

Table 5-5, taken from Monk and Willis (1987), compares some conventional underdrain

systems.

Table 5-5. Comparison of Underdrain Systems

TYPE

ADVANTAGES

DISADVANTAGES

Nozzles result in greater head loss

Pipe laterals with

Air-scour can be used

Cannot use concurrent air and water

nozzles

Less gravel layers needed

Shallower filter box required

Multiple gravel layers needed

Pipe lateral with

Relatively inexpensive material

Integral air-scour cannot be used

orifices

costs

Gravel layers increase depth of filter box

Simple to construct and install

Precast concrete

Very little head loss

Multiple gravel layers needed

T-Pees

Can be used to form plenum

Integral air-scour cannot be used

Casting and laying is labor intensive

Gravel layers increase depth of filter box

Integral air-scour cannot be used

Ceramic tile block

Good backwash distribution

Requires up to seven layers of gravel

Small head loss

Blocks difficult to handle

Relatively easy to install

Deeper filter box because of gravel and

depth of block

Requires up to seven layers of gravel

Plastic dual lateral

Light to handle

Deeper filter box because of gravel and

block

Small head loss

depth of block

Water and air can be used

Limited flexibility in range of air-scour rates

concurrently

Blocks require care in laying correctly

Good water-to-air distribution

Difficult to construct

With appropriate nozzles air-scour

Plenum with

Deeper box because of plenum

can be used

precast concrete

Extra care is needed to avoid nozzle

Good water-to-air distribution

block and nozzles

clogging

Gravel layer not needed

Wheeler-type

Low head loss

Multiple gravel layers required

System

Good water distribution

Integral air-scour cannot be used

Costly construction requirement

Deeper filter box because of plenum and

gravel layers

Deeper box because of plenum

Water and air can be used

Plenum with

Extra care is needed to avoid nozzle

concurrently

monolithic floor

clogging

Little or no gravel required

and nozzles

Nozzle type must be carefully specified

Nozzles available that can be

adjusted to ensure uniform air

distribution

Air-scour rates can be varied

Deeper filter box because of plenum

Water and air can be used

Plenum with

Less reliable than a monolithic floor

concurrently

precast concrete

Extra care is needed to avoid nozzle

Little or no gravel required

blocks and nozzles

clogging

5-11

Previous Page

Previous Page