UFC 3-280-04

17 DEC 2003

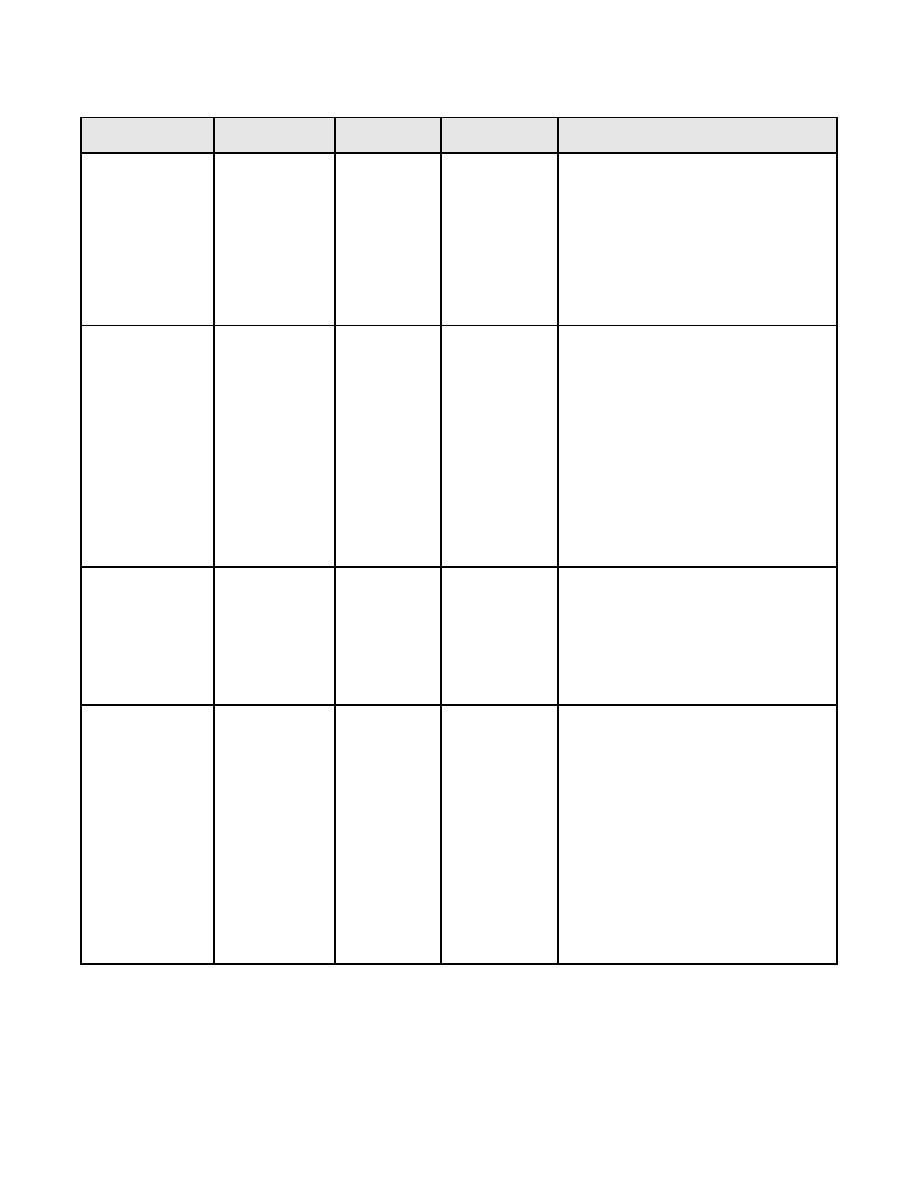

Filtration

Influent

Effluent*

Backwash

Advantages and Disadvantages

Process

Granular media

>2 L/s (30

46 microns

23% of

Low head.

Gravity filter

design flow.

High removal.

gpm)

1.4 (L/s)/m2 (2

10.5 to 14

Larger footprint than pressure filter.

(L/s)/m2 (15 to

gpm)

Needs pump for backwash.

20 gpm/ft2).

< 50 mg/L TSS

Backwash disposal required.

Minimum

High capital cost.

once/day.

Medium operating and labor cost.

Not as susceptible to upsets.

Moderate complexity of control and

operation.

Granular media

>2 L/s (30

510

3 to 5% of

Low head.

Traveling

gpm)

No clear well and no mud well.

microns

design flow.

1.4 (L/s)/m2 (2

bridge filter

Small Footprint.

Controlled by

gpm) dosing.

Air scour available (requiring auxiliary

timer, max

3.5 (L/s)/m2 (5

air supply).

level.

gpm) peak flow

Cannot have high level of solids or oil

Minimum

30 mg/L TSS

and grease.

once/day.

17.5 (L/s)/m2

avg.

Not as high removal efficiency as

(25 gpm/ft2) for

(50 mg/L TSS

gravity up pressure filters.

90 s/cell.

peak)

Backwash disposal required.

High capital and operating cost.

Medium labor cost.

Susceptible to upset.

Complex control and maintenance.

Granular media

>2.5 L/s (40

1030

10 to 25% of

Continuous; no shutdown.

Continuous

gpm) design

microns

design flow.

Not as high removal.

backwash filter

(can operate at

Continuous.

Backwash disposal required.

lower flow)

Auxiliary air required.

30 mg/L TSS

High capital cost.

More susceptible to upset than

pressure filters.

Moderate controls and maintenance.

Cartridge

1 to 2 mg/L

< 1 micron

None with

High removal.

filter

TSS

Flow and

disposable

Not economical for high solids.

at <3 L/s (48

removal

filter elements.

Certain solids can qualify used

gpm).

rating varies

elements as a hazardous waste.

5 to 10 mg/L

per filter

Low capital, operating and labor cost

TSS

element.

for correct application.

at 0.3 to 0.6

Common

Not susceptible to upsets but may be

L/s (5 to 10

filter

easily blinded by high solids loading

gpm).

elements:

system.

10 to 15 mg/L

Woven wire

Is not complex and requires little

TSS

5 m.

maintenance other than element

at < 0.3 L/s (5

Woven fabric

change out.

gpm).

10 um.

Few controls and little auxiliary

Cartridge 1

equipment.

um.

4-2

Previous Page

Previous Page