UFC 3-280-04

17 DEC 2003

CHAPTER 4

PROCESS SCREENING AND SELECTION

4-1

QUICK GUIDE. Table 4-1 provides a quick guide for selecting filtration sys-

tems based on the waste stream parameters described in Chapter 3. The design pro-

fessional can use this table to identify one or two filtration system options upon which to

base his or her design. Using Chapter 5, the design professional can then become fa-

miliar with the specific filtration system and complete the design process. Where two fil-

tration systems appear to be applicable, system-specific costs can be examined to de-

termine which is more cost effective.

4-2

GENERAL. It should be noted that all filters are susceptible to upsets or foul-

ing that will manifest themselves as either blinding or poor effluent quality. For some

systems, recovery, after the problem causing the upset has been corrected, can be as

simple as replacing the filter elements (in the case of cartridge and bag filters) or back-

washing the filters for the prescribed backwash cycle (in the case of pressure and grav-

ity deep bed filters). In other cases, the fouling may have permeated the entire filter.

This is particularly the case with traveling bridge filters, which have relatively shallow

filter beds, and continuous backwash filters, which use the entire bed. Recovering from

an upset with these filters generally involves more extensive backwashing and clean-

sing and can often require that supplemental backwash water or clean process water be

provided to effectively clean the filter medium.

All systems require some manner of process control. Controls may be rela-

tively simple, such as a head loss shutoff for cartridge and bag filter systems to the

complex flow equalization and backwash controls required for traveling bridge and pres-

sure filter systems. Controls required for continuous backwash and gravity filters are

generally of moderate complexity, lying somewhere between these extremes.

As with all process equipment, manufacturers generally offer add-on controls

and system monitoring options to suit individual application needs.

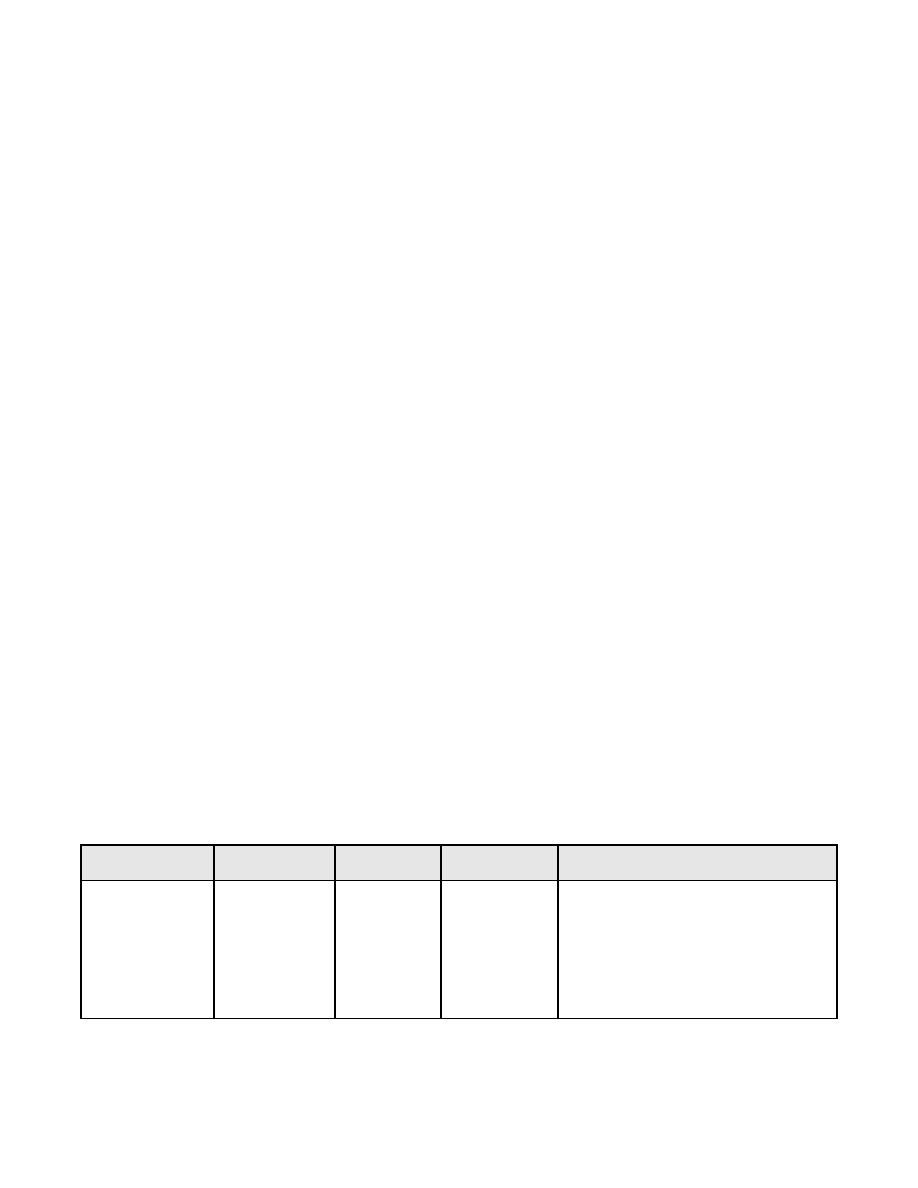

Table 4-1. Filtration System Selection Guide

Filtration

Influent

Effluent*

Backwash

Advantages and Disadvantages

Process

Granular media

>2 L/s (30

46 microns

1% of design

High removal.

Pressure filter

gpm)

flow.

Does not require flow equalization.

3.5 (L/s)/m2 (5

10.5 to 14

Backwash disposal required.

(L/s)/m2 (15 to

gpm)

High capital cost.

(7 (L/s)/m2 (10

20 gpm/ft2).

Medium operating and labor cost.

gpm peak)

Minimum

Not as susceptible to upsets.

< 50 mg/L TSS

once/day.

Moderate complexity of control and

operation.

4-1

Previous Page

Previous Page