UFC 3-280-04

17 DEC 2003

chemical interaction, electrostatic forces, electro-kinetic forces, or van der Waals forces

are strong enough to cause particles to deviate from streamlines. Adsorption is not be-

lieved to be a significant removal mechanism under normal filtration conditions.

3-1.2.4 The effect of filter rates on the quality of filtrate can vary widely, depending on

application. Both the waste stream and any upstream pretreatment (e.g., polymer addi-

tion) can result in changes in the acceptable range of feed rates. Generally, large solids

are removed initially at the surface by straining. As the hydraulic gradient increases,

these flocs may break up and penetrate further into the filter media. As the solids be-

come lodged between the media grains, the void space decreases, and resistance to

flow increases. The rate of flow increases through the larger openings and lessens

though the clogged openings. There is little or no deposition in the channels where ve-

locities are high. Backwash is initiated when the resistance increases to a limiting level

or breakthrough occurs.

3-1.3

Filtration Applications. When specifying a filtration system, it should be

noted that numerous solids separation techniques other than filtration may be applicable

to a given situation. More importantly, from a design standpoint, filtration may not be the

most efficient means of removing solids and the design professional should be aware of

its limitations.

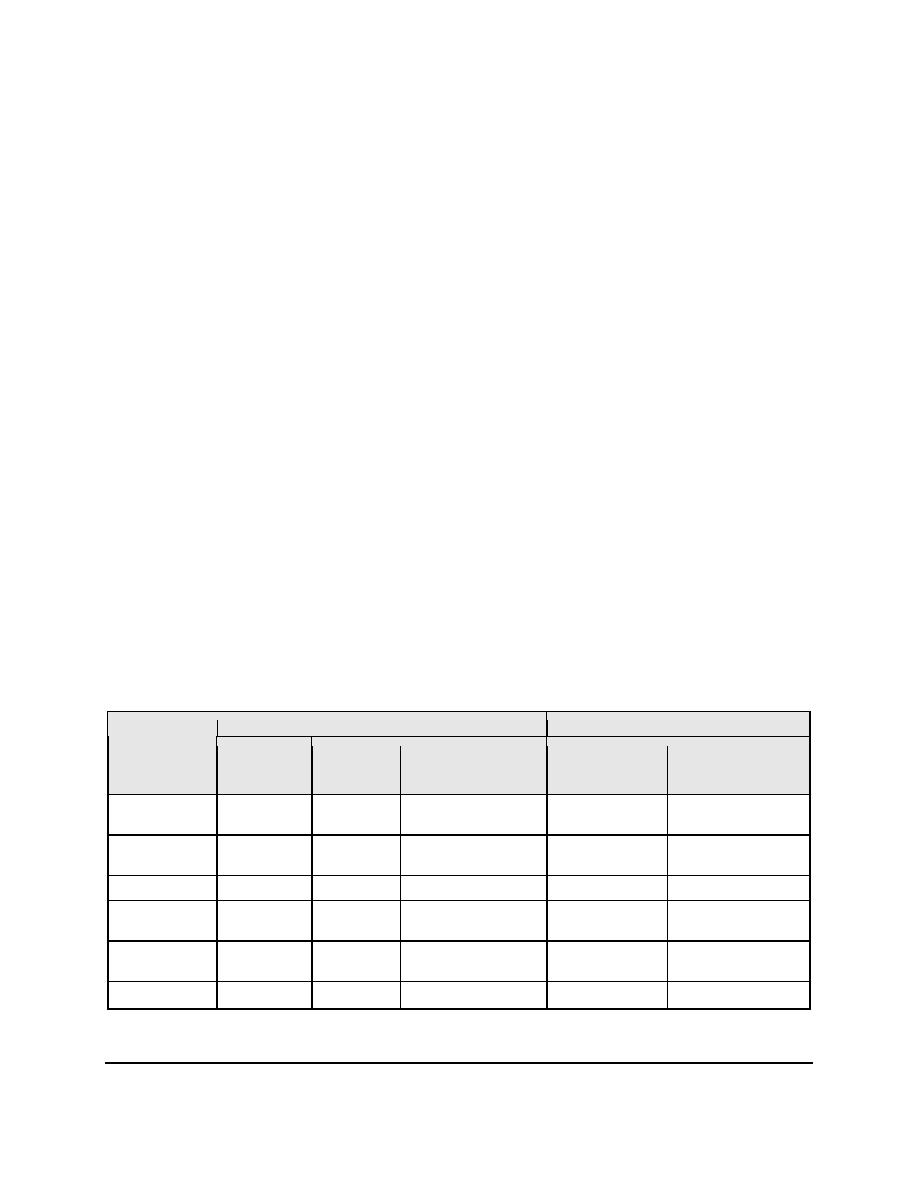

Ideally, the design professional should have a detailed knowledge of all avail-

able options to make proper design decisions. However, Table 3-1 provides a compara-

tive summary of solids separation techniques that can be used as a starting place for

assessing options. Similarly, Figure 3-1 provides a visual representation of available

treatment options based on particle size.

Table 3-1. Comparative Summary of Solids Separation Techniques

Product parameters

Favorable field conditions

Unit

Solid in

Liquid in

Suitability of

Solids

Solids

Operation

Liquid

Solid

Filtrate for use as

Concentration

Characteristics

Stream

Stream

Backwash Water

Filtration

Fair to Good

Good

Good

High to medium

Light, coarse to

med. floc. fine

Sedimentation

Fair to

Poor

CCD*, low efficiency

Medium to low

Dense, medium or

excellent

flocculated fine

Centrifugation

Fair

Poor

Fair to excellent

Medium to low

Dense fine

Cycloning

Poor

Poor

Poor

Low to medium

Dense, coarse to

medium

Screening

Poor

Poor to fair

Poor

High to medium

Coarse to medium

(DSM)†

Ultrafiltration

Excellent

Poor to Fair

Poor

Low

Very Fine

* Counter current decantation

†

Dutch State Mines

Source: Swilzbin (1996)

3-2

Previous Page

Previous Page