UFC 3-280-03

23 JULY 2003

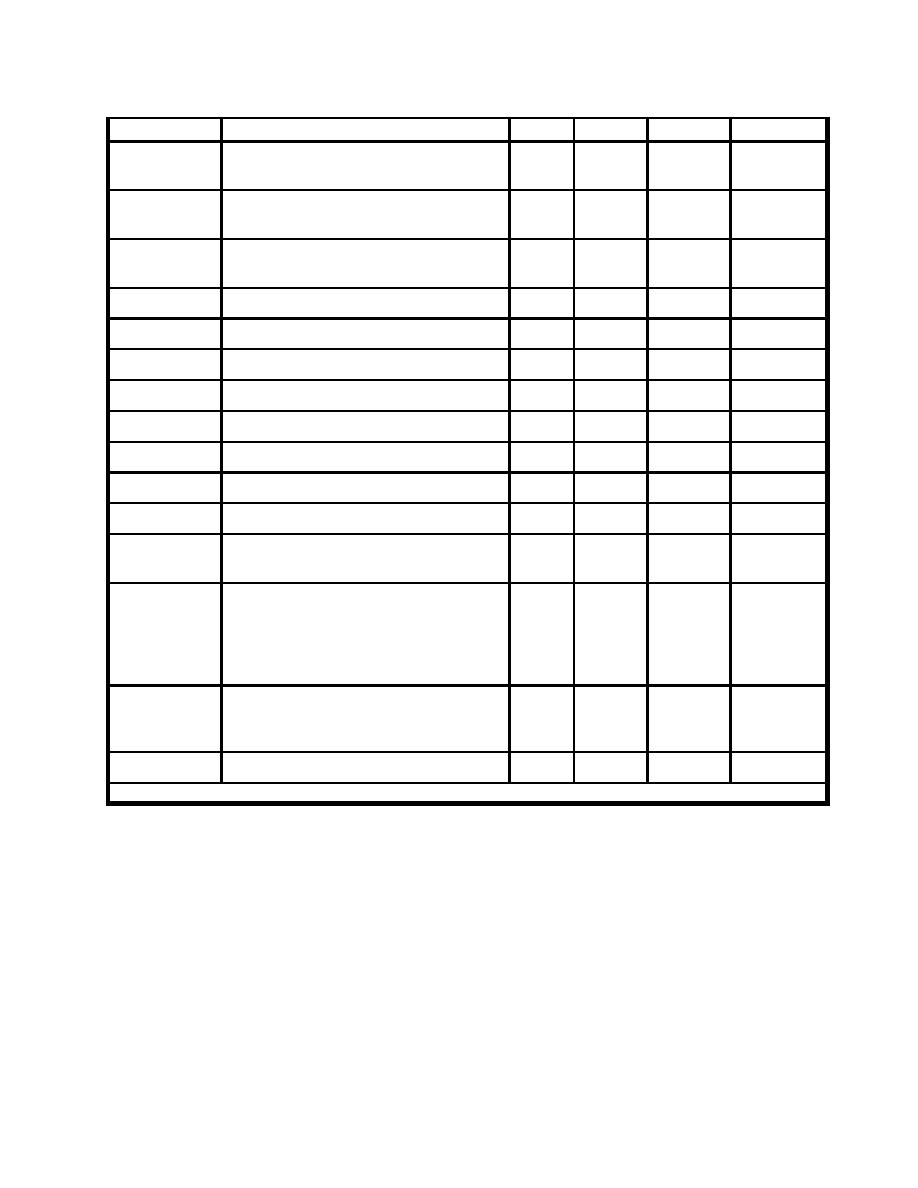

Cloth

caulking grooves

Replace gaskets that have cuts, abraded

X

areas, or separations (if applicable)

Clean sealing areas of excessive solids

X

buildup

Wash cloths with either water or acid or

X

both

Replace cloths and gaskets

X

Inspect for leakage

X

Check for correct clamping pressure

X

Check for correct relief valve setting

X

Check oil level in hydraulic reservoir

X

Replace oil in hydraulic reservoir

X

Clean oil filter element

X

Replace oil filter element

X

Bleed water traps to plant water to press

X

and feed pumps

Clean, or replace, air filter elements

Hydraulic Cabinet

X

Shifter

X

Feed Pump

X

Clean Exhaust Silencers

X

Hydraulic Cabinet

X

Feed Pump

Clean Plate Shift or Guide Rods

X

* More frequent filter medial washing with water may be required.

2-9.6.1 Cleaning. Equipment should be cleaned for general housekeeping as well as

for maintaining it in proper operating conditions.

2-9.6.1.1 Filter Plates and Filter Media Cleaning. Cleaning of filter plates and filter

media is an important aspect of maintaining filter press performance, as well as pre-

venting damage to equipment. During the filter cycle, sludge particles remain on the

filter media owing to repeated use or because of poor cake release and eventually

become imbedded in the cloth, causing blinding. Blinding results in poorer sludge cake

quality and longer cycle times because a less effective area is available for filtrate to

exit. Blinding can also result in plate damage from deflection caused by unequal filter

cake formation and unequal pressure distribution.

2-85

Previous Page

Previous Page