UFC 3-280-03

23 JULY 2003

After completing several recirculation cycles, turn the acid pump off. After the

acid pump is turned off, follow with an air blowing cycle, similar to that

described for the normal sludge filtration cycle, to purge acid from the filter

press.

Close all acid feed and recirculation valves.

Open all normal press operation valves.

2-9.5.2 Variable-Volume Press Operation. A typical sequence of operation for a

variable-volume plate and frame filter press is described below. For this sequence of

operation, it is assumed that the variable-volume press system is fully automatic and

equipped with a core blowing system and a fully automatic wash system that allows a

high-pressure water wash on both sides of the filter media. The typical automatic

operation sequence is as follows:

2-9.5.2.1 The closure device is engaged, closing all the chambers of the press.

2-9.5.2.2 The feed pump is started, and the feed is introduced at the initial specified fill

flow rate and pressure.

2-9.5.2.3 After the initial fill cycle is completed, high-pressure water is pumped into the

diaphragms at the minimum specified pressure, causing the diaphragms to expand and

the sludge to dewater to its appropriate dryness.

2-9.5.2.4 After the sludge is dewatered to the appropriate dryness, the feed pump is

stopped and compressed air is blown through the feed pipe and filtrate manifold to

remove any remaining liquids. The water in the diaphragms is also removed, and the

diaphragms are returned to their original position.

2-9.5.2.5 The hydraulic closure device is then depressurized and the filter plates are

separated, allowing the sludge cake to discharge.

2-9.5.2.6 Following sludge cake removal, the filter media are washed on both sides, if

required, and then returned to its original position.

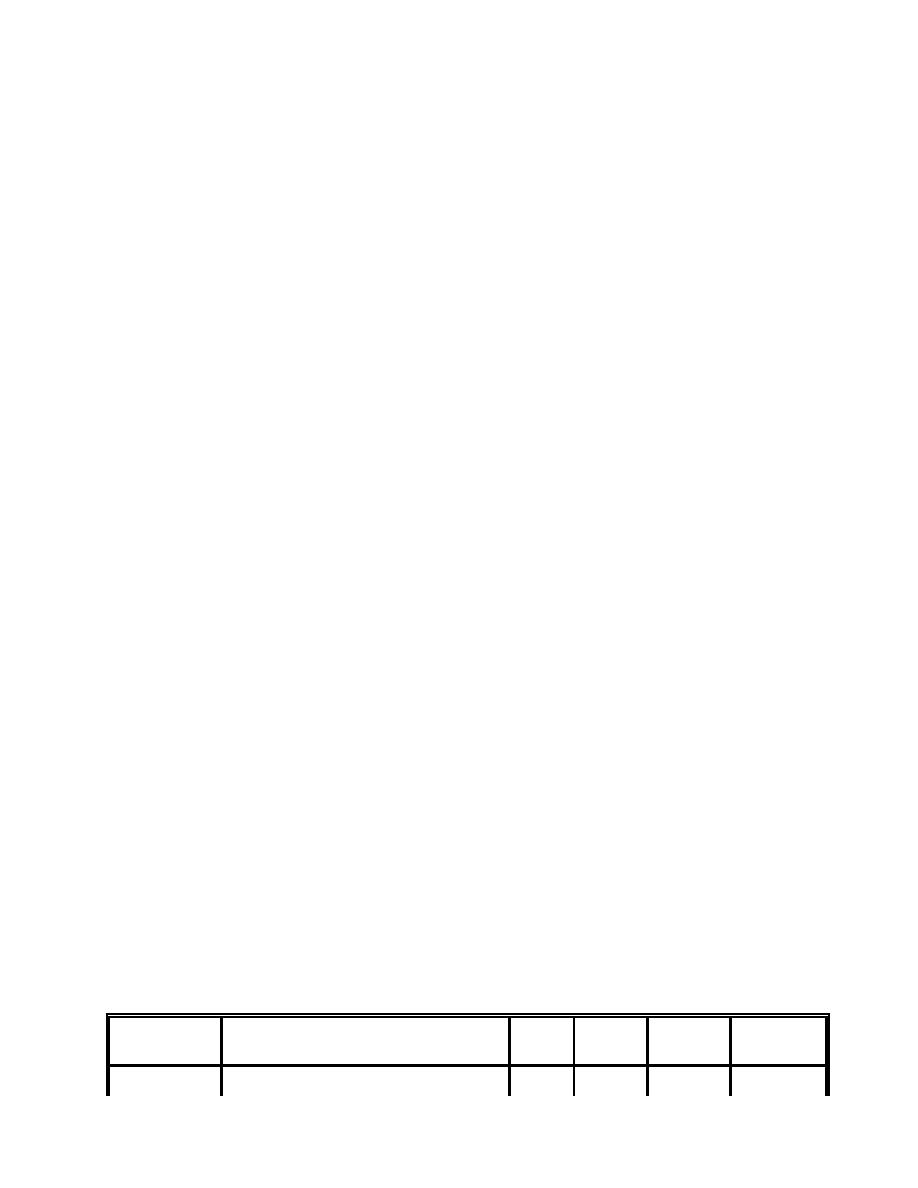

2-9.6

Maintenance Requirements. Maintenance for filter presses includes

measures to keep normal operation on track, such as cleaning and lubrication, and

preventive maintenance, such as periodic inspections and replacement of worn

equipment. A summary of typical parameters and schedule of normal and preventative

maintenance is presented in Table 2-10.

Table 2-10. Typical parameters and schedule for normal and preventive mainte-

nance for filter press equipment.

General

Category

Item

Daily

Weekly

Monthly

Annually

Plate and

Check for cloth holes or cloths out of

X

2-84

Previous Page

Previous Page